Permanent Magnet Synchronous Motor Price Guide: How to Find the Best Deal for Your Needs

The demand for PMSMs is increasing due to the growing adoption of electric vehicles (EVs), renewable energy systems (like wind turbines), and robotics. EVs are a particularly large market for PMSMs, with PMSMs used in nearly 90% of modern electric vehicle motors. The global PMSM market was valued at USD 19.28 billion in 2022 and is projected to reach USD 30.92 billion by 2030, growing at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. When it comes to industrial machinery, robotics, renewable energy systems, or electric vehicles, Permanent Magnet Synchronous Motors (PMSMs) have become a top choice due to their efficiency, compact design, and performance. However, the permanent magnet synchronous motor price can vary significantly depending on several factors. For businesses or individuals looking to invest in a PMSM motor, understanding the elements that influence its cost and how to find the best deal for your needs is crucial. This comprehensive guide will help you navigate the complexities of PMSM motor pricing, providing tips on what to look for, where to buy, and how to get the best value for your investment.

Introduction

The PMSM motor is becoming increasingly popular in a range of applications due to its high efficiency, compact design, and low maintenance requirements. Unlike traditional motors, PMSMs utilize permanent magnets in the rotor, which eliminate the need for external power excitation. This results in lower energy consumption, reduced size, and enhanced performance.

However, when considering the purchase of a permanent magnet synchronous motor, the price is a key factor in the decision-making process. The cost of PMSMs can vary based on several factors such as power rating, brand, material quality, and application. Whether you're an engineer sourcing motors for a manufacturing project, or an entrepreneur interested in a high-performance motor for an electric vehicle, understanding what impacts the PMSM motor price will help you make a more informed choice.

What is a Permanent Magnet Synchronous Motor?

Before delving into the pricing factors, it's important to understand what a PMSM motor is and how it works.

A Permanent Magnet Synchronous Motor is a type of synchronous motor that uses permanent magnets embedded in the rotor to generate the magnetic field necessary for operation. This eliminates the need for additional current-carrying windings in the rotor, which is a characteristic of traditional synchronous motors. PMSMs offer several advantages over other motor types, such as:

- Higher Efficiency: PMSMs are known for their high efficiency, with typical efficiency rates between 90% to 96%, depending on the quality of the motor. This is higher than the typical AC induction motors, which usually range between 80% to 90%.

- Compact Design: The absence of rotor windings allows for a more compact design, making PMSMs ideal for applications where space is limited.

- Low Maintenance: Because there are no brushes or commutators, PMSMs have lower maintenance requirements compared to other types of motors.

- Precise Speed Control: The synchronous nature of PMSMs allows for highly accurate speed and torque control, making them ideal for precision applications.

These benefits make PMSMs particularly useful in applications ranging from industrial automation and robotics to electric vehicles and renewable energy systems.

Factors Affecting the Price of Permanent Magnet Synchronous Motors

The permanent magnet synchronous motor price can vary depending on a variety of factors. Understanding these elements will help you better assess the motor’s value and make the right purchasing decision.

Motor Size and Power Rating

The power rating and size of a PMSM motor are directly linked to its cost. Larger, more powerful motors with higher torque capabilities will generally come with a higher price tag. For example, motors used in electric vehicles or industrial machinery may have a much higher power rating than those used in smaller applications, which drives up the price.

- Low-Power Motors: These typically range from 0.5 kW to 5 kW and are more affordable, often used in smaller devices or light industrial applications.

- High-Power Motors: Motors used in large industrial machinery, wind turbines, or electric vehicles can range from 10 kW to over 100 kW. These high-power PMSMs tend to be more expensive due to the complexity and materials used.

Material Quality (Magnets and Windings)

One of the most significant factors influencing the permanent magnet synchronous motor price is the quality of the materials used in its construction. The rotor of a PMSM motor is equipped with permanent magnets, and these magnets can vary significantly in quality. High-performance magnets, such as rare-earth magnets (e.g., neodymium), contribute to higher costs but provide better efficiency and performance. On the other hand, ferrite magnets are less expensive but offer lower performance.

- Rare-Earth Magnets: These are used in premium PMSM motors and offer excellent magnetic strength, which results in better overall efficiency and performance.

- Ferrite Magnets: More cost-effective and often used in budget-friendly motors, ferrite magnets offer lower efficiency but are a viable option for less demanding applications.

Additionally, the type of winding material used in the motor also affects its cost. Copper windings are common due to their superior conductivity, but they are more expensive than aluminum windings.

Motor Efficiency and Performance

Efficiency plays a critical role in determining the cost of a PMSM motor. Motors with higher efficiency ratings are typically priced higher due to the precision manufacturing and high-quality components involved. Higher efficiency motors also provide long-term cost savings, as they consume less energy and have longer lifespans, making them ideal for industries where continuous operation is crucial.

Higher-performance PMSMs with precise speed control, high torque, and minimal loss are typically priced at the premium end of the market. These motors are used in applications where reliability, precision, and energy efficiency are paramount.

Manufacturer and Brand

The reputation of the manufacturer or brand can significantly affect the PMSM motor price. Renowned brands often charge a premium due to their reputation for quality, reliability, and customer support. These companies also provide warranties, technical support, and higher-grade components.

However, lesser-known or emerging brands may offer PMSM motors at a lower price point, but they may not always deliver the same level of performance or durability. It's essential to balance brand reputation with motor performance and application requirements when making your purchase.

Customization and Special Features

Another factor affecting the permanent magnet synchronous motor price is the customization or specialized features you require. Custom motors designed for specific applications (e.g., motors with unique size, shape, or torque requirements) can be significantly more expensive than standard models. Additional features, such as built-in encoders, cooling systems, or advanced control systems, can also add to the cost of the motor.

Types of Permanent Magnet Synchronous Motors

There are several types of PMSM motors, each with its own set of advantages and price points.

Surface-Mounted PMSMs

Surface-mounted PMSMs have magnets attached to the surface of the rotor. These motors are simpler in design, making them less expensive compared to other types. They are commonly used in applications requiring moderate power and efficiency, such as fans, pumps, and small electric vehicles.

- Advantages: Simpler design, lower cost, and reliable performance.

- Applications: Electric vehicles, home appliances, robotics.

Interior Permanent Magnet Synchronous Motors (IPMSMs)

In IPMSMs, the magnets are embedded within the rotor. This design offers higher performance, particularly in terms of torque density and efficiency. IPMSMs are generally more expensive due to the complexity of their design and the materials used.

- Advantages: High torque density, greater efficiency, and superior performance.

- Applications: High-performance electric vehicles, industrial automation, wind turbines.

Axial Flux PMSMs

Axial flux PMSMs are a newer type of motor that uses a different rotor configuration to achieve greater efficiency in a more compact design. These motors have gained attention for their potential use in electric vehicles and other applications requiring high power-to-weight ratios. Due to their innovative design, axial flux PMSMs tend to be more expensive than conventional motors.

- Advantages: High efficiency, lightweight, and compact.

- Applications: Electric vehicles, renewable energy systems, drones.

Where to Buy Permanent Magnet Synchronous Motors

Direct from Manufacturers

Purchasing PMSM motors directly from manufacturers may offer cost advantages, particularly if you're buying in bulk. Manufacturers often provide discounts for large orders and can offer customized motors that meet your specific requirements. However, dealing directly with manufacturers may require more effort in terms of communication and negotiation.

- Pros: Bulk discounts, customized options, direct support.

- Cons: Limited product variety, longer lead times.

Distributors and Retailers

Authorized distributors and online retailers offer a wide variety of PMSM motors from multiple manufacturers. These platforms often provide excellent customer service, warranties, and return policies, making it easier for buyers to navigate the process.

- Pros: Wide selection, reliable customer service, warranties.

- Cons: May have higher prices due to reseller margins.

International vs. Local Suppliers

When purchasing PMSM motors, it’s important to consider whether to buy locally or internationally. Local suppliers may have higher prices due to shipping and import duties, but they offer quicker delivery times and easier access to customer service. On the other hand, international suppliers may offer lower prices, but shipping and customs fees can add up quickly.

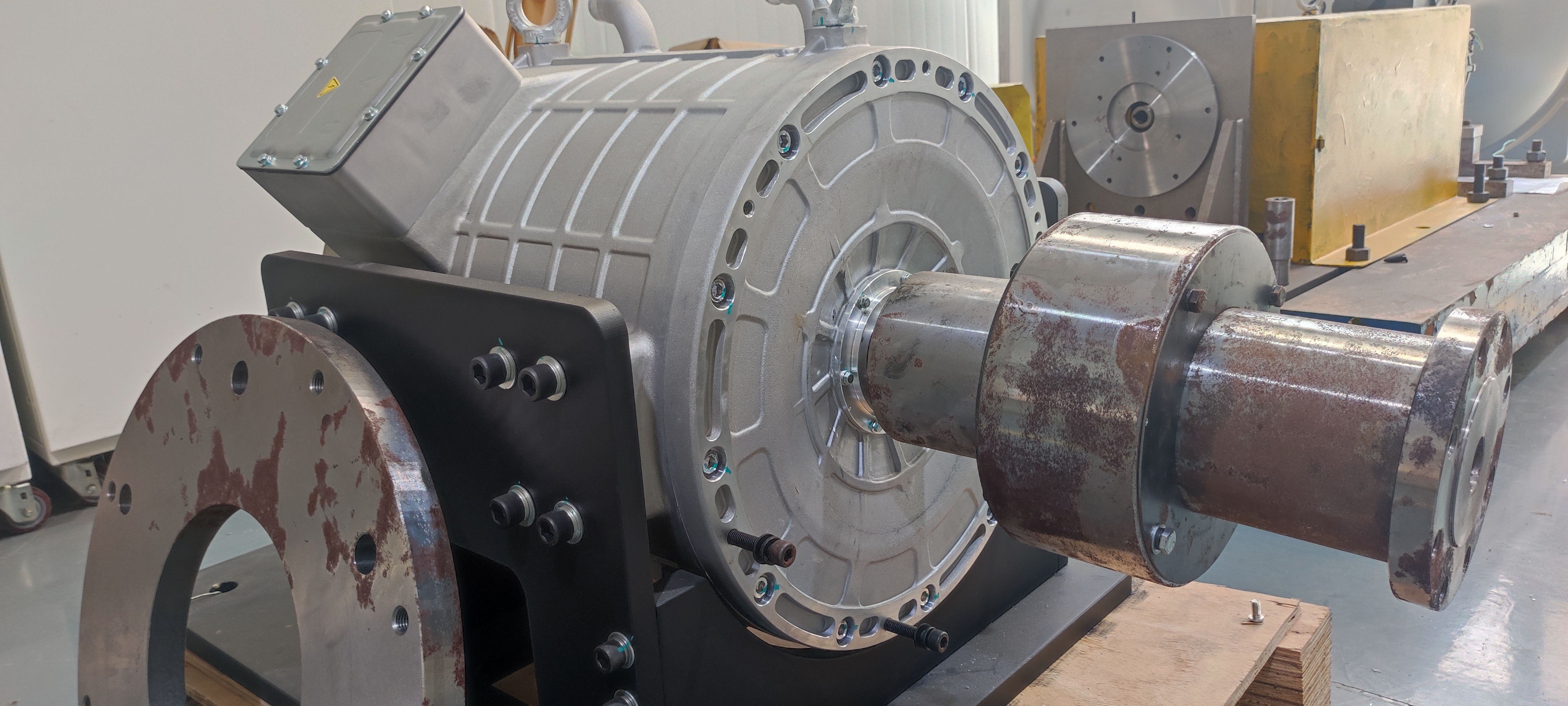

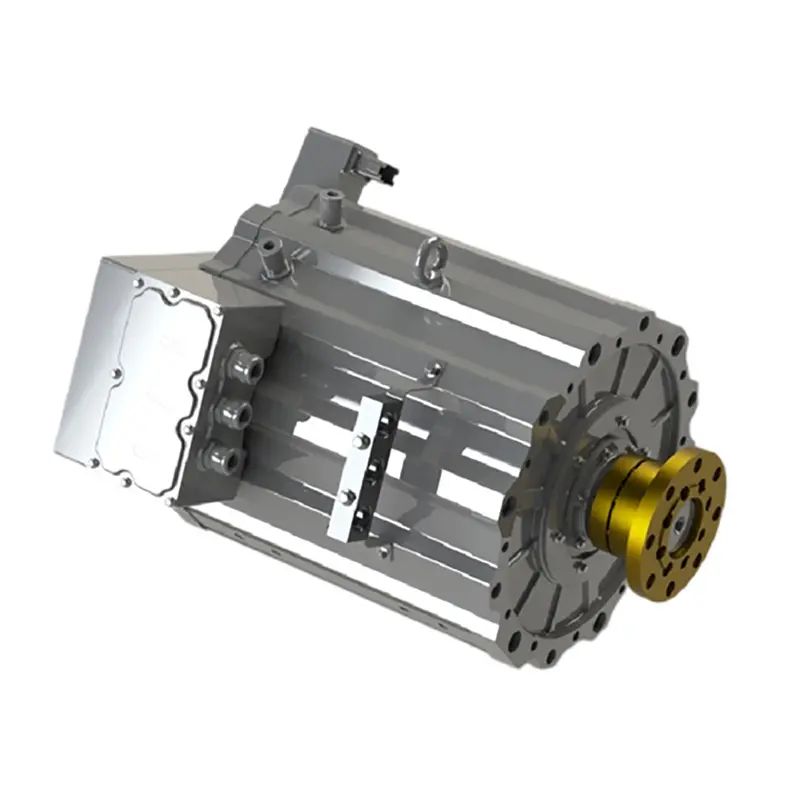

PUMBBA is a prominent provider of high-efficiency electric vehicle drive systems. We specialize in designing and manufacturing permanent magnet synchronous motors (PMSM), electric vehicle motor controllers (MCU), vehicle controllers (VCU), and power supply systems for electric vehicles (DCDC, DCAC, OBC, PDU), all tailored to suit a diverse range of commercial electric vehicles. Our integrated solutions are designed to meet the varying needs of electric vehicle drive platforms.

Price Range and Cost Estimates

- Low-End PMSMs

- Low-power PMSMs, typically ranging from 0.5 kW to 5 kW, are suitable for less demanding applications and are priced between $100 to $1,000 depending on the motor's size and features. These motors are often used in smaller devices like appliances or light-duty industrial equipment.

- Mid-Range PMSMs

- Mid-range motors, typically with power ratings between 5 kW and 30 kW, can cost anywhere from $1,000 to $10,000. These motors are commonly used in applications such as small electric vehicles, robotics, and automated systems.

- High-End PMSMs

- High-power PMSMs used in large-scale applications, such as electric vehicles, industrial automation, and renewable energy systems, can cost anywhere from $10,000 to $100,000 or more, depending on the motor's specifications, efficiency, and additional features.

Cost Comparison with Other Motor Types

- PMSM vs. AC Induction Motors: While PMSMs are more expensive upfront than AC induction motors, their lower energy consumption and higher efficiency can lead to significant cost savings over time. For example, a PMSM might cost 30-50% more than an AC induction motor, but the operational costs of the PMSM are usually 10-20% lower.

- PMSM vs. Brushless DC Motors (BLDC): Although BLDC motors are similar to PMSMs, PMSMs tend to be more expensive due to their high-performance characteristics and greater torque density. However, PMSMs offer better efficiency and longer life spans compared to BLDC motors.

How to Find the Best Deal for Your Needs

To find the best permanent magnet synchronous motor price for your needs, it's important to:

- Understand Your Requirements: Match motor specifications to your application. Don’t overpay for features you don’t need.

- Compare Multiple Suppliers: Request quotes from different suppliers and compare their offerings.

- Consider Long-Term Costs: Factor in the total cost of ownership, including maintenance, energy consumption, and potential repairs.

- Negotiate: Don’t hesitate to negotiate with suppliers, especially if you’re making a bulk purchase.

Common Mistakes to Avoid When Buying PMSMs

- Overestimating Power Needs: Avoid overspending on high-power motors if your application doesn't require them.

- Ignoring Efficiency: Lower-efficiency motors may seem cheaper upfront but cost more in the long run due to higher energy consumption.

- Neglecting Warranties and Support: Ensure you’re buying from a reliable vendor that offers warranties and after-sales support.

Conclusion

Choosing the right permanent magnet synchronous motor requires careful consideration of several factors, including motor size, material quality, efficiency, and application. By understanding what influences the PMSM motor price, you can make a more informed decision and find a motor that offers the best value for your needs.