The Ultimate Guide to Electric Drive Axle

Electric vehicles (EVs) are rapidly changing the automotive landscape, and at the heart of this transformation is a range of innovative technologies. One of the most vital components in modern EVs is the electric drive axle. Understanding this crucial element is key to grasping how electric vehicles deliver power efficiently and effectively. This ultimate guide will delve deep into the workings, components, and importance of electric drive axles.

Introduction to Electric Drive Axles

The rise of electric vehicles (EVs) has triggered a wave of innovation in the automotive sector, shifting the way cars are powered, designed, and manufactured. A critical part of this transformation is the electric axle, which plays a vital role in how electric vehicles operate. Unlike traditional vehicles that rely on combustion engines and complex mechanical linkages, electric axles harness the power of electricity to drive the wheels directly.

The shift towards electric powertrains means that the drivetrain components, such as the axle, must be rethought for the demands of an EV. The electric drive axle is at the forefront of this change, offering simpler, more efficient, and more reliable solutions compared to traditional axles. Understanding the components, advantages, and future potential of electric drive axles is crucial for anyone interested in the future of the automotive industry.

What is an Electric Drive Axle?

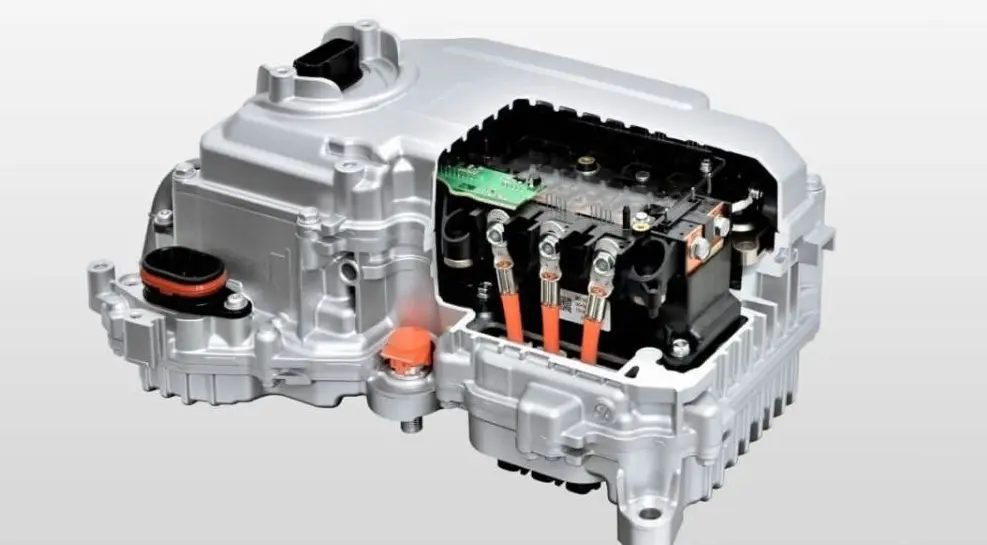

An electric drive axle is a specialized axle system used in electric vehicles to transmit power from the motor to the wheels, ultimately propelling the vehicle forward or backward. Unlike conventional internal combustion engines (ICE) that require complex transmissions, gearboxes, and other mechanical components, the electric axle integrates several components into a unified unit, simplifying the drivetrain.

At its core, an electric drive axle consists of an electric motor, gears, a differential, and often additional systems for cooling and power management. The electric motor is typically powered by a battery pack, which stores and supplies electrical energy to the motor. This streamlined design allows for improved energy efficiency, reduced weight, and more precise control over the torque delivered to each wheel.

The key advantage of the electric axle is that it integrates all necessary components into a single, compact unit, reducing the number of mechanical parts that require maintenance or adjustment. This results in lower operational costs and less wear and tear on the vehicle.

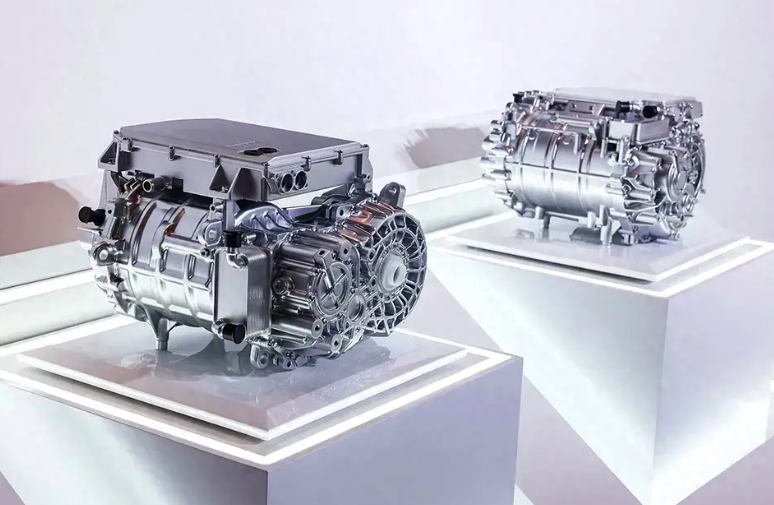

Components of an Electric Drive Axle

To fully appreciate the functionality of the electric drive axle, it's important to understand its various components. These elements work together to ensure smooth and efficient power transfer from the electric motor to the wheels. Here’s a breakdown of the primary components:

a. Electric Motor

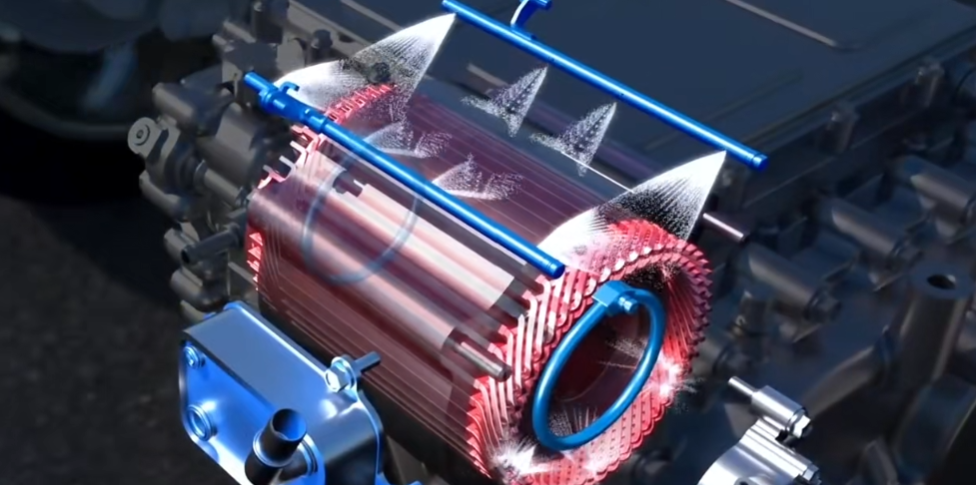

The electric motor is the most important part of the electric axle. It converts electrical energy from the vehicle’s battery into mechanical energy, which is used to turn the wheels. Electric motors can vary in size, design, and power output, but they typically operate on the principle of electromagnetic induction, where electrical current creates a magnetic field that causes a rotor to spin.

Electric motors used in electric drive axles are designed to be highly efficient and provide excellent torque characteristics, especially at low speeds. This makes electric motors ideal for vehicles that need instantaneous acceleration, like EVs. Additionally, because electric motors can deliver torque directly to the wheels, they eliminate the need for a complex transmission system, simplifying the drivetrain.

b. Differential

The differential is a critical component of the axle that allows the wheels on the same axle to rotate at different speeds. This is particularly important when the vehicle turns. When a car turns a corner, the inside wheel needs to rotate slower than the outside wheel to avoid excessive tire wear. The differential is responsible for adjusting the rotational speed of each wheel to accommodate these differences in speed.

In the case of electric axles, the differential is often integrated with the electric motor and other drivetrain components into a single unit, reducing the complexity of the entire system. The use of an electric motor means that the differential is directly driven by electricity rather than through mechanical linkages, which improves overall efficiency.

c. Transmission/Gearbox

While traditional vehicles often use multi-speed gearboxes to adjust the vehicle's speed and torque, most electric drive axles utilize a simpler single-speed transmission. This is because electric motors can deliver a broad range of speeds without the need for complex gear shifting, making a multi-speed transmission unnecessary in many cases.

However, some advanced electric drive axles—particularly those in high-performance electric vehicles—may include a multi-speed transmission or a system that can optimize torque delivery to improve acceleration or energy efficiency. This allows for more precise control over the power output and can enhance driving performance in specific applications.

d. Axle Shaft

The axle shaft is a long metal rod that connects the electric motor to the wheels. It transmits the rotational force (torque) generated by the motor to the wheels, causing them to spin. The axle shaft plays an important role in maintaining the structural integrity of the drivetrain while ensuring that power is efficiently delivered to the wheels.

e. Cooling System

Electric motors generate significant heat during operation, especially when delivering high torque. To prevent overheating, electric axles are equipped with cooling systems that regulate the temperature of the motor and other critical components. These systems typically use a combination of air and liquid cooling, with specialized radiators, pumps, and heat exchangers to maintain optimal performance levels.

In high-performance applications, such as electric sports cars, cooling becomes even more critical, as the electric motor and drive components are under constant heavy load. Effective cooling helps prevent thermal degradation of components and ensures that the vehicle operates at peak efficiency.

How Electric Drive Axles Work

The working principle of an electric drive axle is based on the same basic principles as any other electric motor. However, the way this power is transmitted to the wheels differs from traditional mechanical drivetrains. Here's a detailed look at how electric drive axles function:

a. Power from the Battery

In an electric vehicle, the battery stores electrical energy. When the driver accelerates, this energy is supplied to the electric motor. The motor uses this electrical power to generate mechanical energy that drives the wheels.

b. Motor Rotation

Once the motor receives power, it begins to rotate. Electric motors operate on the principle of electromagnetism, with a stator (the stationary part) creating a magnetic field, and a rotor (the moving part) spinning in response to this field. The rotation of the motor generates torque, which is the force needed to move the vehicle.

c. Power Transmission

The rotating motion of the motor is transferred to the axle shaft, which is connected to the differential. In some systems, there may also be a transmission that helps adjust the speed and torque before it reaches the axle.

d. Torque to Wheels

As the power moves through the axle shaft and differential, it is split and delivered to the wheels. The differential ensures that each wheel rotates at the proper speed, especially when the vehicle turns.

e. Vehicle Movement

Once the wheels receive the torque, the vehicle begins to move. In this system, the power is delivered directly to the wheels, allowing for smooth acceleration and deceleration. This direct-drive approach eliminates the need for a complex transmission system, making the drivetrain more efficient.

Types of Electric Drive Axles

1.Half Rear Axle

A half rear axle is characterized by its simple design, low cost, and ease of maintenance, which makes it popular in traditional internal combustion engine (ICE) vehicles. However, with advancements in new energy vehicle (NEV) technology, the drive axle is evolving to meet the needs of electric powertrains. For example, electric drive can be achieved by integrating motors and reducers.

Key Features:

- Low system efficiency

- High development and production costs

- Significant space usage, making it challenging to integrate the power battery pack

- Excellent NVH (Noise, Vibration, Harshness) performance

- Heavy weight

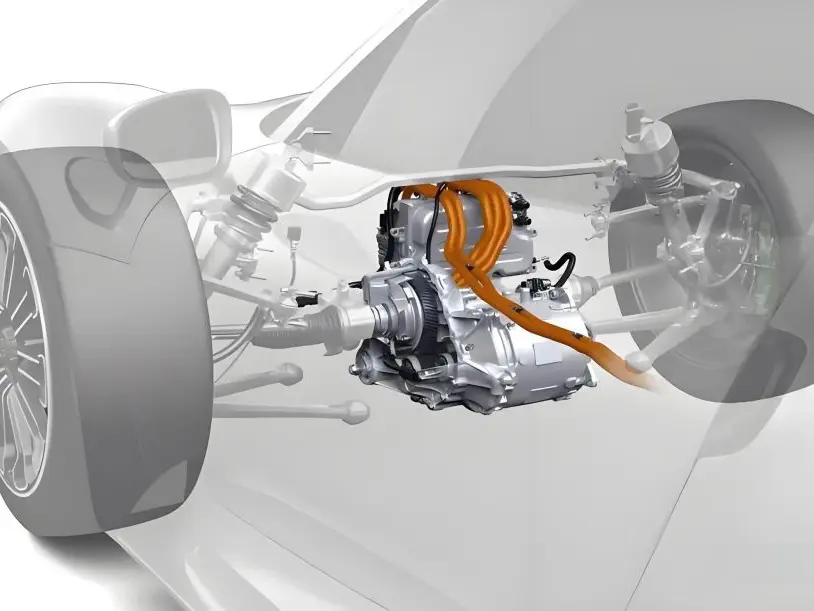

2.Central Drive System

In this system, the drive motor is combined with the transmission, replacing the conventional engine and transmission to take advantage of the electric motor’s high-speed capabilities.

Key Features:

- Low system efficiency

- Simple development and low manufacturing costs

- Large space requirements, complicating battery pack placement

- System weight is similar to traditional setups

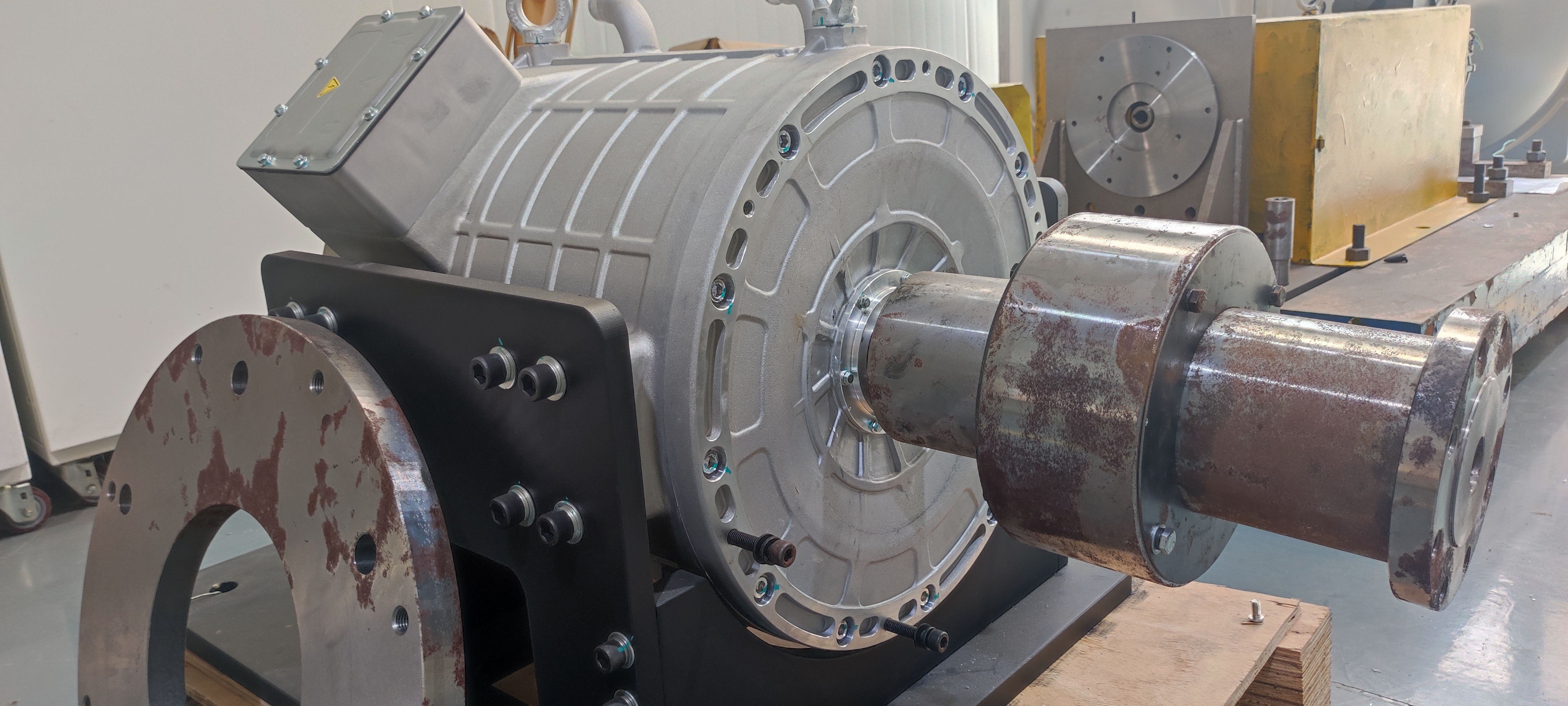

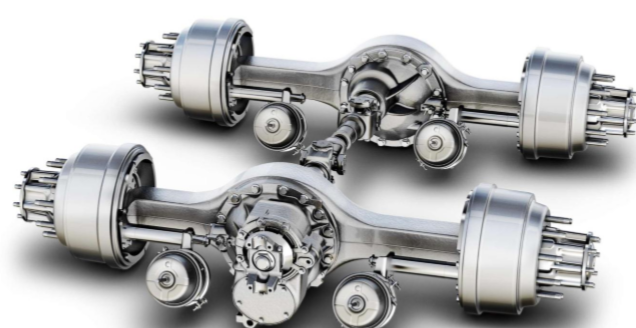

3.Co-axial/Parallel Shaft Electric Drive Axle

This system integrates the motor with a traditional drive axle. After reduction and torque enhancement, it directly powers the wheels.

Key Features:

- Eliminates the need for components like drive shafts and suspension brackets, reducing weight and installation costs

- High transmission efficiency and compact design, aiding in power battery pack integration

- Poor NVH performance

- Large unsprung mass, negatively affecting vehicle handling

Parallel shaft electric drive axles are increasingly used in light and medium commercial vehicles, although their adoption has been slower due to the need for new development of reducers. However, their benefits include the use of mature fuel vehicle components like the axle housing, wheel edge, and brakes, which offer reliability, good load-bearing capacity, and overload resistance. The downside is the heavy unsprung mass, which impacts comfort.

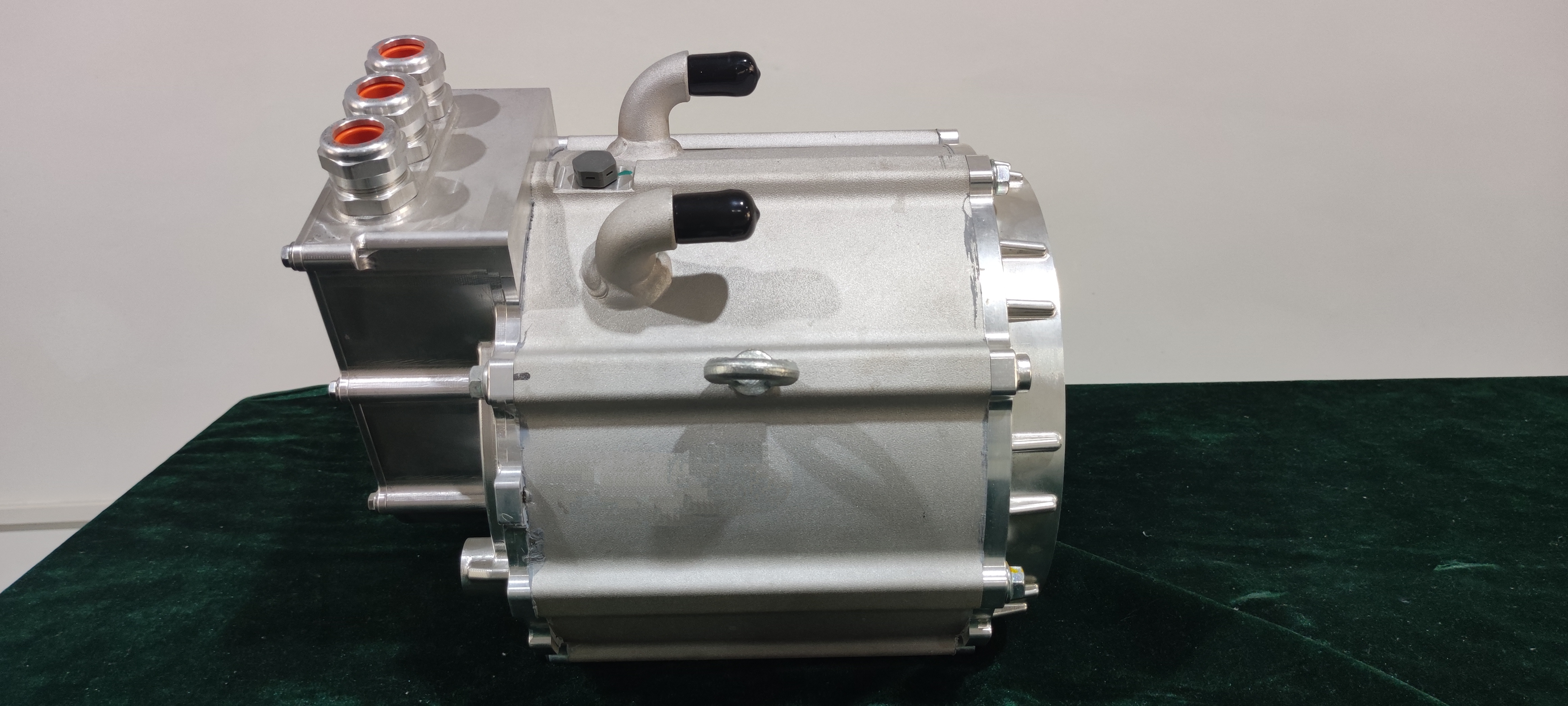

4.Wheel Side Electric Axle

This configuration integrates the motor with the reducer and traditional drive axle, optimizing the underfloor space, eliminating the drive shaft, and offering more flexibility in vehicle layout.

Key Features:

- Suitable for pure electric buses with high transmission efficiency

- Small space footprint, facilitating easier placement of the power battery pack

- High unsprung mass, which can affect vehicle handling

5.In-Wheel Drive Axle

In this system, a direct-drive in-wheel motor is highly integrated with the drive axle, directly powering the wheels. This design represents the future direction of electric vehicle drive technology.

Key Features:

- Highest transmission efficiency

- Compact size, light weight, and low energy consumption

- Nearly 100% braking energy recovery efficiency, thanks to the large outer diameter of the motor

This system is currently best suited for electric buses and large trucks.

Advantages of Electric Drive Axles

There are numerous benefits to incorporating electric drive axles into electric vehicles. These advantages make the technology increasingly popular in the automotive industry:

a. Efficiency

One of the biggest advantages of electric axles is their efficiency. Since the motor directly drives the wheels, there are fewer energy losses compared to traditional drivetrains, which rely on complex mechanical linkages, transmissions, and gears.

Electric motors are more efficient than internal combustion engines, especially at lower speeds. This results in improved energy consumption and extended range for the vehicle.

b. Compact Design

Because the electric drive axle integrates multiple components into a single unit, it takes up less space and weighs less than traditional drivetrains. This allows manufacturers to create vehicles with more interior space or a larger battery pack for longer driving range.

c. Reduced Maintenance

Traditional vehicles with internal combustion engines have many moving parts that require regular maintenance, such as oil changes, gear adjustments, and transmission repairs. The electric drive axle has far fewer components that need maintenance, which reduces long-term ownership costs.

Challenges and Considerations

While electric drive axles offer many benefits, they also present some challenges and considerations for manufacturers and consumers:

a. Cost

Electric drive axles can be more expensive to produce compared to traditional axles due to the cost of the electric motor and associated components. However, as production volumes increase and technology improves, the costs are expected to decrease over time.

b. Power Requirements

High-performance vehicles may require more power than a single electric drive axle can provide. In such cases, manufacturers may need to integrate dual or multi-motor systems, which can add complexity and cost.

c. Heat Management

Electric motors generate heat, and managing this heat effectively is crucial to maintaining performance and longevity. Cooling systems must be designed carefully to prevent overheating, particularly in high-performance applications.

Applications of Electric Drive Axles

Electric drive axles are used in a wide variety of vehicles, including:

- Passenger Cars: Most modern EVs, including those from brands like Tesla, Nissan, and Chevrolet, use electric drive axles for efficient power delivery.

- Trucks and Buses: Many electric trucks and buses use electric drive axles for superior energy efficiency, especially in commercial and urban applications.

- Electric Bikes and Scooters: Smaller electric vehicles, such as e-bikes and scooters, often rely on electric drive axles for direct power delivery and compact design.

The Future of Electric Drive Axles

As the demand for electric vehicles continues to grow, electric drive axles will play an even more important role. Innovations in materials, battery technology, and power electronics will continue to improve the performance and efficiency of these systems. The adoption of electric drive axles will also be driven by the need for sustainability and environmental responsibility.

Expect to see electric drive axles in an increasing variety of vehicles, from commercial trucks to personal vehicles, as the automotive industry moves toward electrification. Moreover, advancements in autonomous driving and smart mobility will require even more sophisticated drivetrain solutions, which could further improve the integration of electric drive axles.

Conclusion

The electric drive axle is a critical element in the evolution of electric vehicles, enabling manufacturers to build more efficient, compact, and powerful electric drivetrains. By simplifying the drivetrain and reducing the need for complex mechanical components, electric drive axles help to increase energy efficiency, improve performance, and reduce maintenance requirements.

With the continued rise of electric vehicles and the focus on sustainability, electric drive axles are set to become an essential component of tomorrow's vehicles. Whether for personal cars, commercial vehicles, or specialized applications, the electric drive axle is helping to shape the future of transportation.

Read More: Choosing the Right Motor Controller for Your Electric Vehicle