VCU in Electric Vehicles: The Brain Behind Energy Management and Power Distribution

Electric vehicles (EVs) are at the forefront of modern transportation, combining sustainability, efficiency, and cutting-edge technology. Unlike traditional vehicles powered by internal combustion engines, EVs rely on sophisticated electrical systems for propulsion, safety, and user experience. At the core of this intricate system is the Vehicle Control Unit (VCU), often described as the brain of an electric vehicle.

The VCU market is expected to grow at a CAGR of 16% from 2023 to 2028, driven by increasing EV adoption and advancements in autonomous driving technologies. The VCU plays an indispensable role in ensuring the seamless operation of all subsystems within the EV. From managing energy distribution and controlling power flow to monitoring performance and enabling advanced functionalities, the VCU ensures the vehicle operates at peak efficiency. In this blog, we’ll take a deep dive into the role, functionality, and innovations associated with the VCU in electric vehicles while exploring the challenges and breakthroughs shaping its development.

What is a VCU (Vehicle Control Unit)?

The Vehicle Control Unit (VCU) is an advanced electronic control module designed to act as the central intelligence hub of an electric vehicle. It oversees, regulates, and coordinates the operation of various critical subsystems, including the battery, motor, power electronics, and auxiliary systems.

Unlike conventional vehicles, where multiple independent control units handle specific functions, the VCU in electric vehicles integrates and streamlines these tasks. This level of integration ensures:

Efficient communication between systems.

Optimal energy management.

Enhanced vehicle performance and reliability.

The VCU uses high-speed communication protocols, such as the Controller Area Network (CAN) bus, to exchange real-time data with other components, such as the Battery Management System (BMS) and motor controllers. This allows it to make instant decisions, ensuring the vehicle operates seamlessly under various conditions.

By acting as the central command system, the vehicle control module enhances the EV’s overall intelligence, enabling features like adaptive driving modes, energy recovery through regenerative braking, and predictive maintenance.

The VCU in Electric Vehicle's Role in Energy Management

One of the primary functions of the VCU in electric vehicle in electric vehicles is energy management. VCUs work closely with Battery Management Systems (BMS). Advanced thermal management systems controlled by VCUs can improve battery efficiency by 25%, especially in extreme climates. Efficient VCU operations can reduce battery degradation rates by 20%, extending battery life significantly. EVs rely on batteries as their sole source of energy, making efficient energy use critical for maximizing range, performance, and battery life. The vehicle control module performs several vital tasks to ensure optimal energy utilization:

1. Optimizing Battery Usage

The VCU in electric vehicle works closely with the Battery Management System (BMS) to monitor and regulate the state of charge (SOC) and state of health (SOH) of the battery. It ensures the battery operates within safe voltage and temperature ranges while preventing overcharging or excessive discharge, which could damage the cells.

2. Regulating Regenerative Braking

Regenerative braking is a key feature in EVs, allowing the vehicle to recover energy during deceleration. The VCU in electric vehicle oversees this process, capturing kinetic energy and converting it into electrical energy that is stored back in the battery. This extends the vehicle’s range and improves energy efficiency.

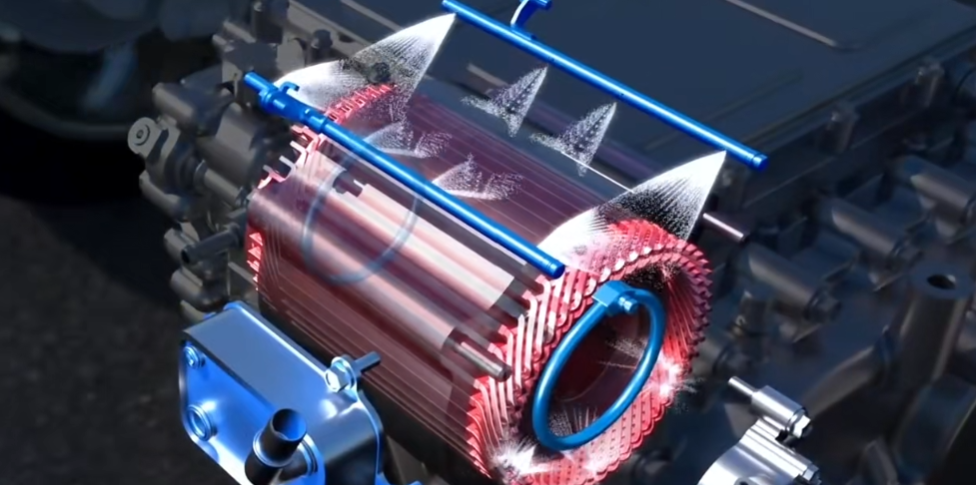

3. Thermal Management

EV batteries and motors generate significant heat during operation. The VCU in electric vehicle manages the thermal systems to maintain optimal operating temperatures, ensuring performance and longevity. This includes activating cooling systems during high loads and heating systems in cold environments to maintain battery efficiency.

Through these functions, the vehicle control module ensures that energy is utilized efficiently, enhancing the driving experience and extending the vehicle’s range.

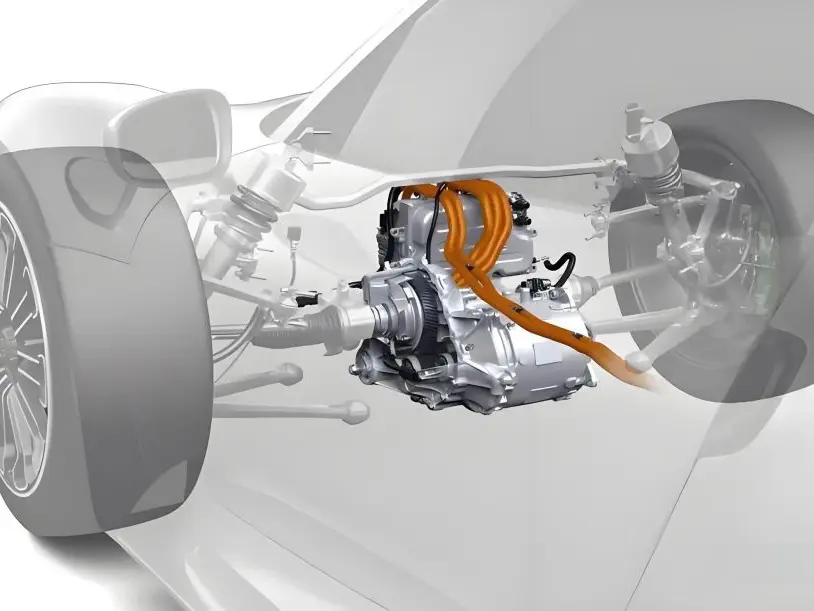

Power Distribution and Control in EVs

The VCU in electric vehicle also plays a critical role in power distribution, managing the flow of electrical energy between the battery and other components such as the motor, inverter, and auxiliary systems.

Key Functions of Power Distribution

- Dynamic Load Management: The VCU in electric vehicle intelligently allocates power based on the vehicle’s current needs. For instance, more energy may be directed to the propulsion system during acceleration, while auxiliary systems like climate control receive lower priority.

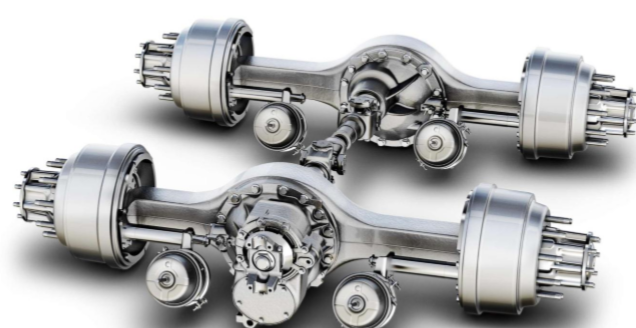

- Motor Control: By communicating with motor controllers, the VCU in electric vehicle ensures smooth torque delivery, efficient power usage, and seamless acceleration and deceleration.

- Fault Detection and Isolation: The VCU continuously monitors the power flow and can detect anomalies such as short circuits or component failures. In such cases, it isolates the fault to prevent further damage and ensure safety.

The precision of the vehicle control module in handling power distribution allows for greater energy efficiency, smooth vehicle operation, and enhanced safety.

Real-Time Monitoring and Adaptive Control

One of the defining features of a modern VCU in electric vehicle is its ability to perform real-time monitoring and adaptive control. These capabilities are essential for maintaining optimal performance in dynamic driving conditions.

1. Real-Time Monitoring

The VCU monitors critical vehicle metrics, including motor speed, battery voltage, current levels, and system temperatures. This constant flow of data enables it to:

Adjust power delivery to suit the driver’s demands.

Prevent overheating or overloading of components.

Provide real-time feedback to the driver through the dashboard interface.

2. Adaptive Control

Using advanced algorithms and machine learning, the vehicle control module adapts to changing conditions, such as road surfaces, traffic situations, and weather. For example:

On slippery roads, the VCU can adjust torque distribution to enhance traction.

During steep climbs, it ensures the motor delivers sufficient power without overloading the battery.

3. Predictive Maintenance

The VCU collects data to identify wear and tear in components before they fail, reducing maintenance costs and vehicle downtime. By analyzing trends in performance metrics, it can notify drivers when servicing is required.

These capabilities make the vehicle control module a cornerstone of intelligent vehicle design, offering a safer, more efficient, and enjoyable driving experience.

VCU and System Integration in Electric Vehicles

A key strength of the VCU in electric vehicles is its ability to integrate multiple subsystems into a unified framework. This level of integration is crucial for achieving the reliability and efficiency expected from EVs.

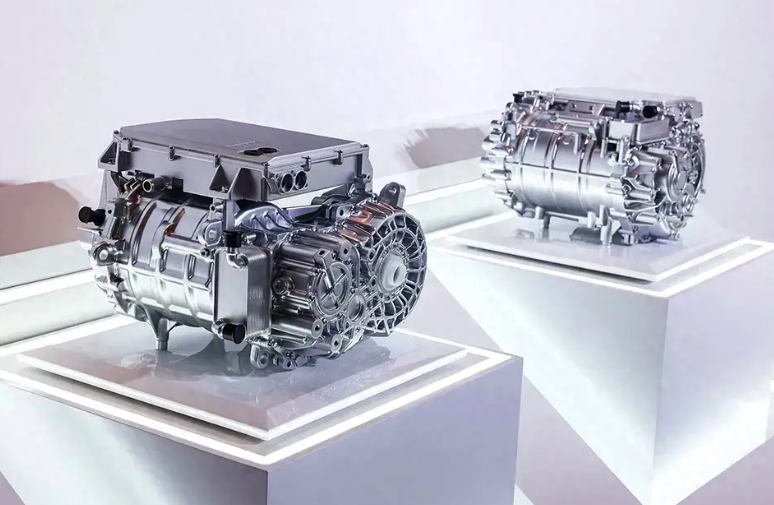

Subsystems Integrated by the VCU

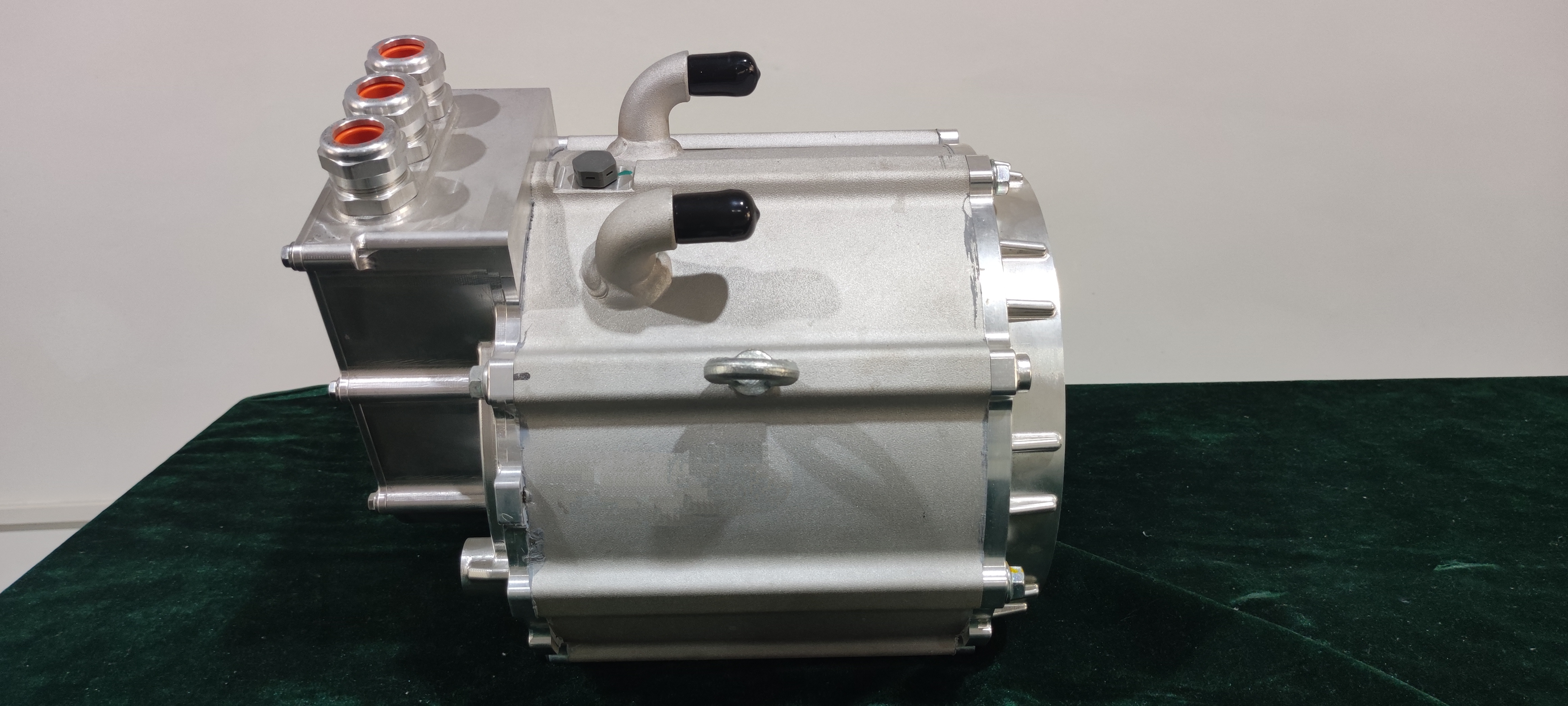

- Battery Management System (BMS): The VCU works in tandem with the BMS to monitor battery health and optimize charging and discharging cycles.

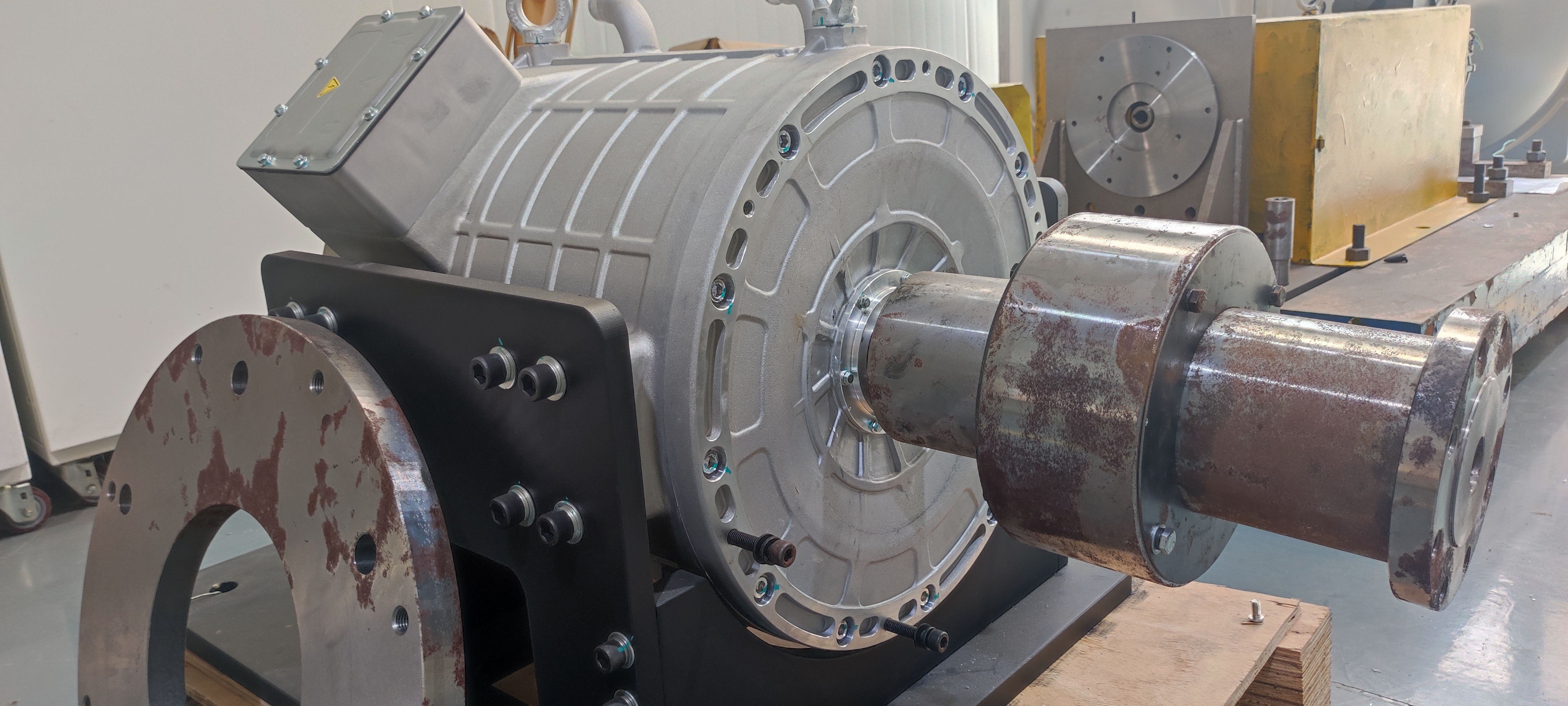

- Motor Controllers: By coordinating with motor controllers, the VCU ensures precise torque delivery and efficient propulsion.

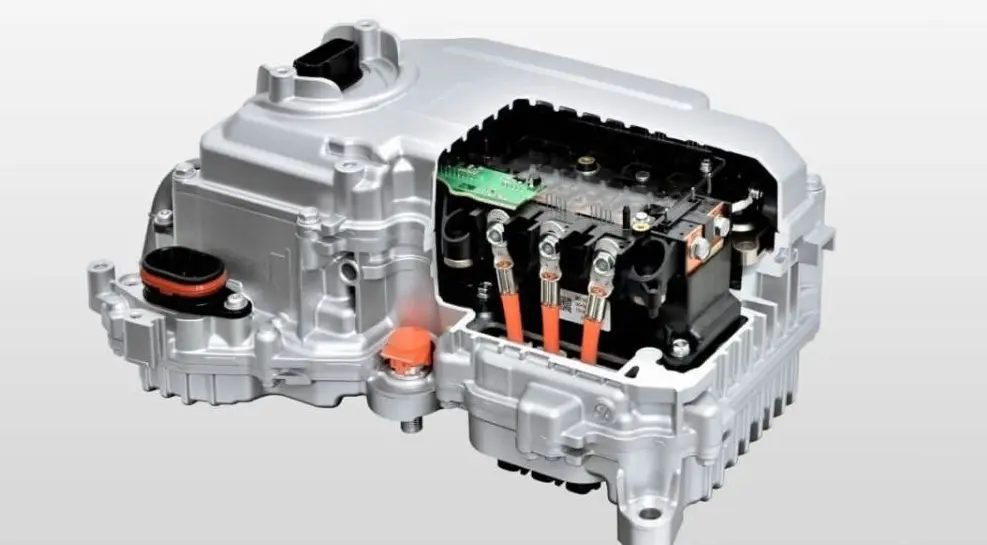

- Power Electronics: The VCU oversees inverters and converters, ensuring the correct voltage and current levels for various components.

- Auxiliary Systems: The vehicle control module also manages auxiliary systems like lighting, climate control, and infotainment, prioritizing power usage when necessary.

This integration simplifies vehicle design, enhances modularity, and ensures seamless operation across all systems.

Challenges and Innovations in VCU Technology

While the VCU is a marvel of engineering, its development and implementation come with challenges.

Key Challenges

- Complex Software Requirements: Developing software that can handle real-time decision-making, adaptive control, and system integration is a daunting task.

- Thermal and Power Management: As EVs become more powerful, managing the heat and energy demands of advanced VCUs requires innovative solutions.

- Cybersecurity: Connected EVs are vulnerable to cyberattacks, making VCU security a top priority for manufacturers.

Innovations in VCU Technology

To address these challenges, manufacturers are investing in innovations such as:

- AI-Driven Algorithms: Enabling VCUs to learn and adapt to driver behavior and environmental conditions.

- Modular Designs: Allowing for easy upgrades and customization based on vehicle requirements.

- Enhanced Thermal Solutions: Using advanced materials and cooling techniques to manage heat dissipation.

These advancements are paving the way for more capable and efficient VCUs that meet the demands of modern EVs.

VCU in the Context of EV Performance and Range

VCUs contribute to performance optimization by managing motor efficiency. A well-optimized motor can improve torque by up to 40%, directly enhancing acceleration. EVs with advanced VCU systems achieve ranges that are 15%–20% higher than those with older-generation control units. The performance and range of an EV are directly influenced by the capabilities of its VCU. By optimizing energy usage, managing power distribution, and enabling regenerative braking, the VCU ensures every watt of energy is utilized effectively.

For example, a well-designed VCU can:

Maximize the range per charge by balancing energy consumption across all systems.

Enhance acceleration and torque delivery, improving the driving experience.

Extend battery life by preventing overuse or inefficient charging cycles.

The VCU’s contribution to these metrics makes it a vital component in delivering high-performance EVs that meet consumer expectations.

Key Manufacturers and Technologies Behind VCU Development

The development of VCUs is spearheaded by some of the world’s leading automotive and technology companies.

Notable VCU Manufacturers

- Bosch: Known for its high-performance VCUs with advanced integration capabilities.

- Continental: Focuses on adaptive VCUs powered by AI and machine learning.

- Tesla: Develops proprietary VCUs tailored to its innovative EV platforms.

Emerging VCU Manufacturers

PUMBAA: PUMBAA EV's Vehicle Control Unit (VCU) is essential for managing and optimizing the performance of electric vehicle motors and controllers. The state-of-the-art Vehicle Electronic Control Unit (ECU) from PUMBAA EV enables seamless communication between various components, improving both efficiency and responsiveness. PUMBAA EV delivers innovative technology that enhances performance and reliability across a wide range of electric vehicles.

These manufacturers are pushing the boundaries of VCU technology, incorporating features like over-the-air updates, AI-driven decision-making, and enhanced connectivity to future-proof their designs.

Conclusion

The VCU in electric vehicles is truly the brain behind their energy management and power distribution systems. By coordinating the operation of various subsystems, the VCU ensures efficiency, performance, and safety in modern EVs.

As the automotive industry continues its shift toward electrification, the role of the vehicle control module will become even more prominent. With advancements in AI, modularity, and cybersecurity, the future of VCUs promises even greater innovations, paving the way for intelligent, sustainable, and high-performance electric vehicles.