What Is The Impact Of Adjustable Speed Drives On Power Distribution?

Introduction

In today’s rapidly evolving industrial and commercial sectors, energy efficiency and sustainability are becoming paramount considerations. Industries are seeking technologies that can help them reduce operational costs, meet sustainability targets, and improve the overall efficiency of their operations. One such innovation is the adjustable speed drive (ASD), a device that offers exceptional control over motor speed, allowing users to optimize performance and save energy.

While the benefits of ASDs for individual motor control are well understood, the implications for broader power distribution networks are less often discussed. As more industries incorporate adjustable speed drives into their operations, understanding the effects on power distribution becomes essential for utilities, engineers, and businesses alike.

This blog explores the significant impact that adjustable speed drives have on power distribution, including their effect on energy efficiency, power quality, and overall system stability. We will also examine the best practices for integrating ASDs into power systems to optimize their benefits while minimizing potential challenges.

Understanding Adjustable Speed Drives (ASDs)

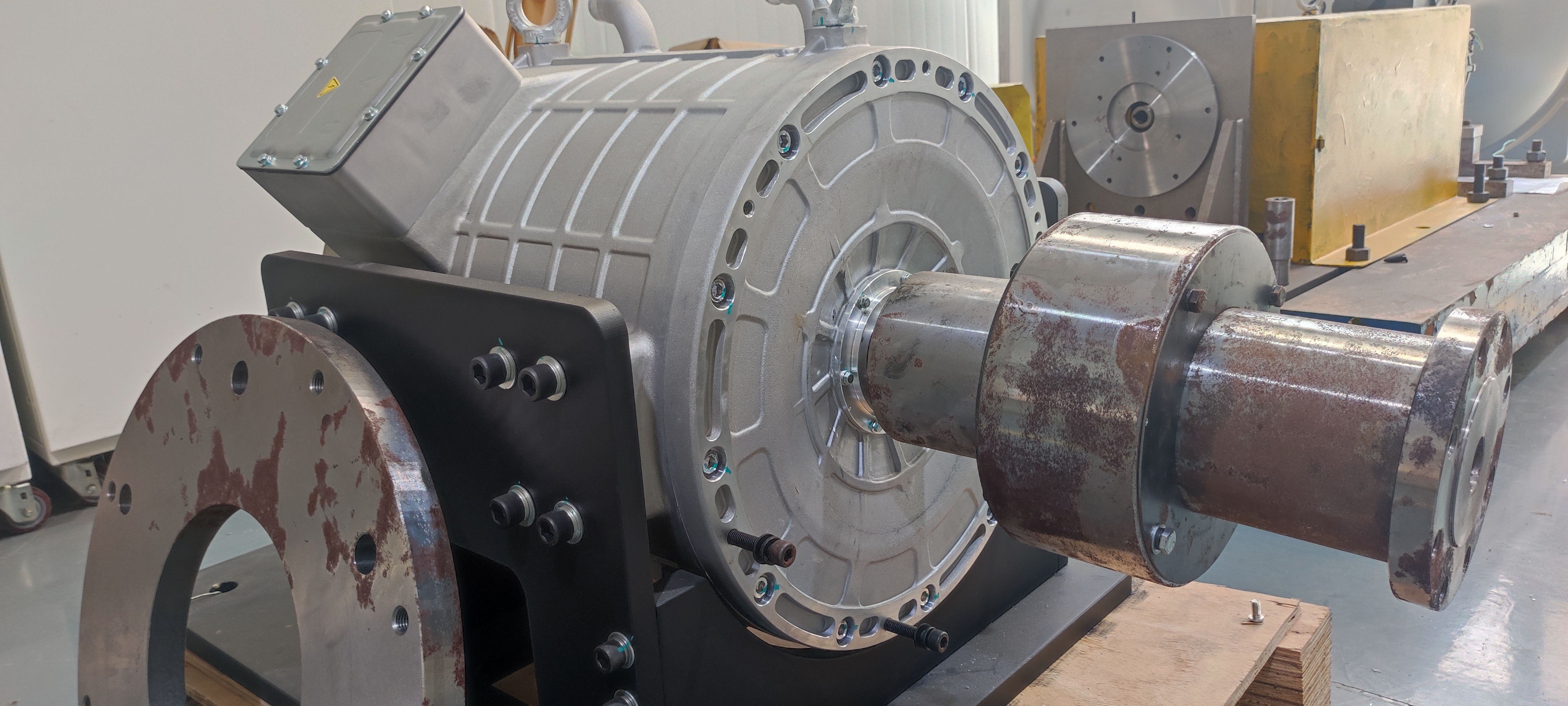

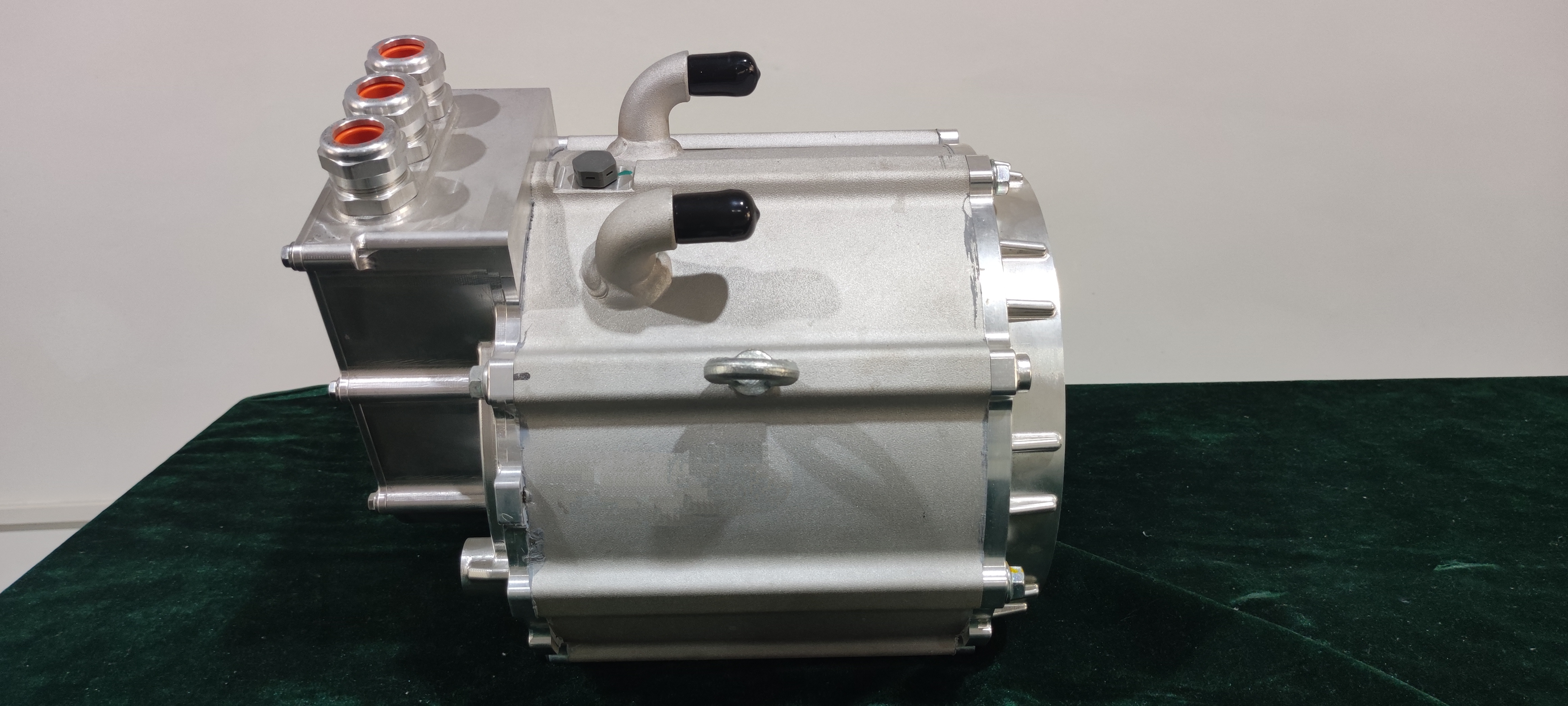

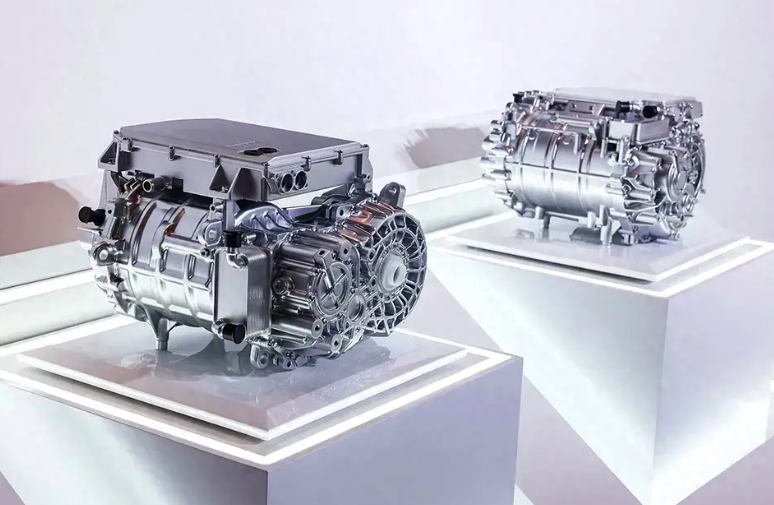

An adjustable speed drive (ASD) is an electronic device designed to control the speed and torque of an electric motor by adjusting the frequency and voltage supplied to it. Unlike traditional motors, which operate at a fixed speed, adjustable speed drives allow motors to vary their speed depending on the load and process requirements, making them highly versatile and energy-efficient.

There are various types of adjustable speed drives, but the most common include:

1.Variable Frequency Drives (VFDs): These are the most widely used form of ASD. VFDs control the speed of the motor by varying the frequency of the power supplied to it.

2.DC Drives: These control the speed of DC motors by adjusting the voltage applied to the motor’s armature.

3.Servo Drives: Used in highly precise applications, servo drives control the position, speed, and torque of a motor with high accuracy.

The three primary components of an adjustable speed drive are:

- Rectifier: Converts incoming alternating current (AC) into direct current (DC).

- Inverter: Converts the DC back into a variable frequency AC that powers the motor, thereby controlling its speed.

- Control Unit: Monitors the motor’s performance, adjusting the output of the drive based on real-time data to maintain optimal operating conditions.

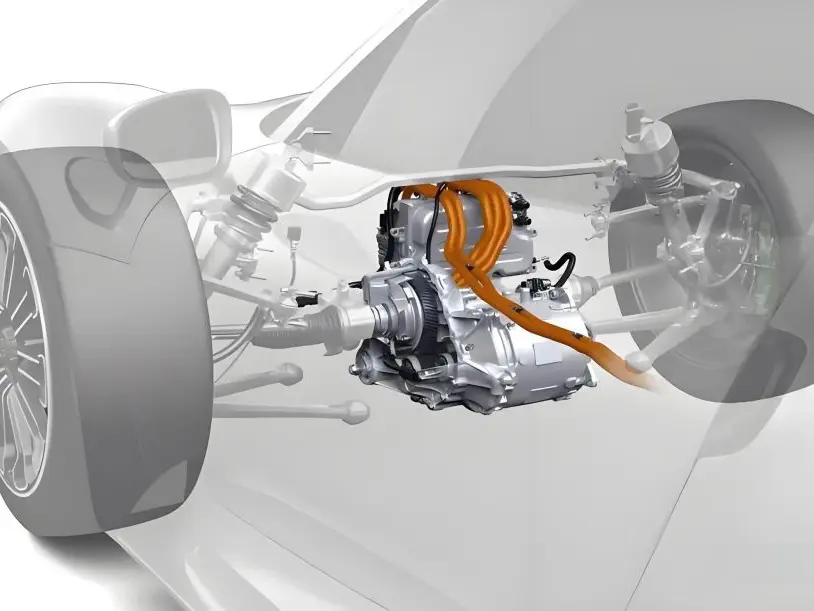

By varying the speed of a motor, ASDs reduce energy consumption, improve system performance, and enhance process control, making them essential in applications such as pumps, HVAC systems, conveyor belts, and fans.

How Adjustable Speed Drives Affect Power Distribution

While adjustable speed drives provide significant energy savings and operational benefits, their integration into power systems also has broader implications for power distribution networks. These impacts stem from the dynamic load behavior, harmonic distortion, and regulatory effects ASDs introduce into the power grid.

a. Load Fluctuations

One of the most noticeable impacts of adjustable speed drives on power distribution is the fluctuation in load. Traditional systems with fixed-speed motors have a constant power demand. In contrast, adjustable speed drives allow motors to operate at varying speeds, meaning their power consumption fluctuates based on the specific requirements of the application.

This dynamic load can lead to a more variable power demand profile, particularly when multiple ASDs are operating in a network. While this variability can be managed with modern grid management tools, utilities must carefully monitor these changes to ensure the stability and reliability of the power distribution system. This becomes particularly important in systems that have multiple ASDs operating simultaneously, as they can introduce unexpected peak demands or cause underloading at certain times.

b. Harmonic Distortion

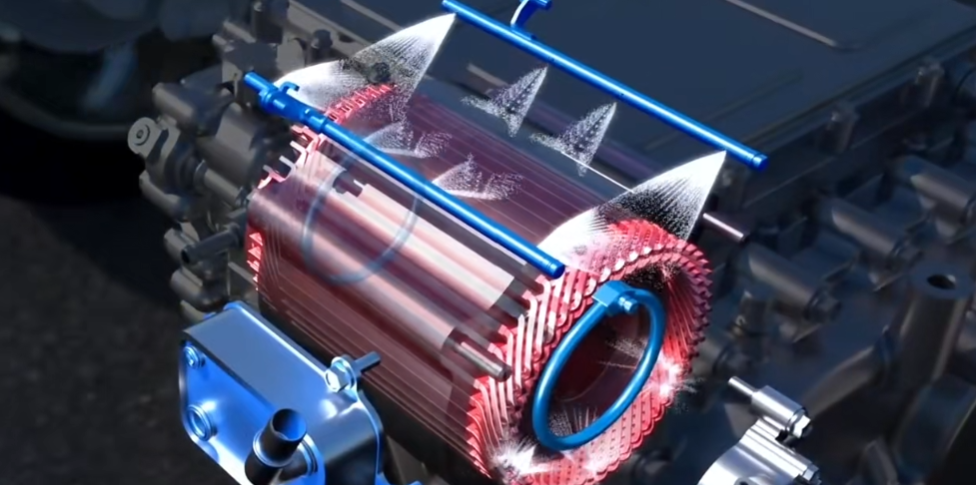

A critical issue associated with the use of adjustable speed drives is the potential for harmonic distortion. When speed drives convert AC to DC and then back to a variable frequency AC, they can introduce harmonic currents into the electrical system. Harmonics are unwanted frequencies that can distort the waveform of the power supply, leading to a range of problems.

These harmonics can have several adverse effects on the power distribution system:

- Overheating of equipment: Harmonics can cause transformers, cables, and other equipment to overheat, reducing their lifespan and efficiency.

- Interference with sensitive equipment: Sensitive devices, such as computers, medical equipment, and communication systems, can experience malfunction or failure due to harmonic distortion.

- Increased losses: Harmonics can increase the resistive losses in the distribution network, making the system less efficient.

Utilities often need to invest in harmonic filters and power conditioning equipment to mitigate these effects. These devices are specifically designed to reduce harmonic distortion and restore power quality, ensuring that adjustable speed drives do not negatively affect the broader electrical system.

c. Voltage and Frequency Regulation

Another challenge posed by adjustable speed drives is their effect on voltage and frequency regulation in power systems. Because ASDs modify the frequency and voltage supplied to motors, they can introduce fluctuations that might affect the overall stability of the power grid.

In some cases, these fluctuations can be significant enough to impact the operation of the grid, especially in older or less flexible systems that may not be designed to handle such dynamic loads. As adjustable speed drives become more widespread, utilities may need to invest in dynamic voltage and frequency regulation technologies to ensure that these variations do not compromise the stability or reliability of the power distribution system.

Energy Efficiency Benefits for Power Distribution

Despite the challenges, adjustable speed drives offer substantial energy efficiency benefits, both at the level of individual machines and the broader power distribution system. These benefits stem from the ability of ASDs to precisely control motor speeds, match power usage with demand, and reduce unnecessary energy consumption.

a. Reduced Power Consumption

The primary benefit of adjustable speed drives is the reduction in power consumption. Traditional systems with fixed-speed motors often run at full power, regardless of the actual demand for the process. This leads to wasted energy when the system is not running at full capacity.

By adjusting motor speed to match the load, adjustable speed drives significantly reduce energy consumption. For example, in an HVAC system, an ASD can reduce the speed of fans when less air circulation is required, thereby saving energy and reducing the load on the power distribution network.

b. Peak Demand Reduction

ASDs also help reduce peak demand, a critical factor in modern power distribution. During times of high demand, utilities often struggle to meet the increased load, requiring the use of less efficient, expensive, or carbon-intensive backup power sources.

With adjustable speed drives, the ability to reduce motor speeds during periods of lower demand helps flatten the load curve. This reduces the peak demand on the grid, alleviating strain on power generation and distribution systems, and helping utilities avoid the need for costly infrastructure upgrades to handle temporary spikes in demand.

c. Energy Recovery

Some adjustable speed drives are capable of recovering energy through regenerative braking, particularly in applications where the load is subject to deceleration, such as in conveyor belts or escalators. Instead of dissipating the energy as heat, the adjustable speed drive feeds it back into the power system, either for immediate use or storage.

This regenerative capability helps recover lost energy and can significantly improve the overall energy efficiency of the system, reducing the total power consumption and load on the power distribution network.

Challenges and Considerations for Power Distribution

Despite their energy efficiency benefits, adjustable speed drives pose certain challenges that need to be addressed when integrating them into power systems. These challenges range from power quality issues to system compatibility, and effective solutions are necessary for maintaining the integrity of the power distribution network.

a. Power Quality Concerns

Harmonic distortion is a significant concern in the operation of adjustable speed drives, as discussed earlier. This issue can degrade the quality of the power supplied to sensitive equipment and create inefficiencies in the system. Addressing these concerns often requires the installation of additional equipment, such as harmonic filters or dedicated grounding systems, to ensure that the power remains stable and clean.

b. System Compatibility

Not all power distribution systems are equipped to handle the dynamic load fluctuations introduced by adjustable speed drives. Older systems may not have the flexibility or capacity to accommodate the additional variability in power consumption, potentially leading to overloading or voltage instability. Upgrading transformers, circuit breakers, and protection relays may be necessary to ensure the system can safely integrate with ASDs.

c. Increased Complexity in Load Forecasting

With the introduction of adjustable speed drives, load forecasting becomes more complex. Traditional load forecasting models rely on fixed, predictable consumption patterns, but the variability in power demand created by ASDs can make it harder to predict overall system load. This requires utilities to adopt more sophisticated forecasting techniques and rely on real-time monitoring systems to accurately assess the load on the power distribution network.

Best Practices for Integrating ASDs into Power Systems

Integrating adjustable speed drives into power systems requires a systematic approach to maximize their benefits while minimizing any potential issues. Below are some best practices for successful integration:

a. Invest in Power Quality Solutions

To reduce the impact of harmonic distortion, utilities and industries should invest in power quality solutions such as harmonic filters, voltage stabilizers, and surge protection devices. These technologies can help ensure that the power supply remains stable and free from distortion, preventing damage to sensitive equipment and maintaining the overall health of the electrical system.

b. Use Energy Management Systems (EMS)

An energy management system (EMS) helps monitor the performance of adjustable speed drives, providing real-time data on power consumption, motor performance, and load fluctuations. This allows for better management of energy use and facilitates the optimization of both motor performance and the overall power distribution system.

c. Regular Maintenance and Monitoring

Regular inspection and maintenance of adjustable speed drives are critical for their optimal performance. Routine checks for issues such as overheating, wear and tear, and system calibration can prevent failures and ensure long-term reliability. Continuous monitoring also helps detect any performance degradation early, allowing for timely intervention and minimizing downtime.

d. Integration with Smart Grid Technologies

As the power grid becomes smarter, integrating adjustable speed drives with advanced smart grid technologies can help balance load fluctuations and optimize energy distribution. By allowing for real-time communication between ASDs and the grid, utilities can dynamically adjust motor speeds, minimize energy consumption, and reduce the overall load on the system.

Conclusion

Adjustable speed drives are revolutionizing the way we think about energy efficiency, both at the level of individual machinery and within the larger power distribution network. They provide tremendous benefits in terms of energy savings, peak demand reduction, and enhanced operational control. However, their integration into power systems presents challenges that require careful planning, monitoring, and investment in complementary technologies.

By adopting best practices for managing power quality, ensuring system compatibility, and utilizing advanced monitoring solutions, businesses and utilities can successfully integrate adjustable speed drives into their operations. In doing so, they can unlock the full potential of this transformative technology while maintaining a stable and efficient power distribution network for years to come.

Read More: What Is A Motor VFD Drive And Why You Need One?