What Is A Motor VFD Drive And Why You Need One?

Introduction

The global market for VFDs is projected to reach $30.5 billion by 2028, growing at a CAGR of 6.4% from 2021 to 2028 (Fortune Business Insights). This growth reflects increasing demand for energy-efficient solutions in both automotive and industrial sectors, with electric vehicles being a significant driver. As the world shifts toward more sustainable and energy-efficient transportation options, electric vehicles (EVs) have emerged as a leading solution to reduce our dependence on fossil fuels and mitigate environmental impact. The internal workings of an electric vehicle, particularly the motor system, play a critical role in achieving these benefits. One of the key components in modern EVs is the Motor VFD Drive (Variable Frequency Drive), which offers remarkable advantages in motor performance, efficiency, and longevity.

In this blog, we will explore the functionality of a motor VFD drive in electric vehicles, how it optimizes motor operation, the different types of VFDs, and why integrating this technology into your electric vehicle system is essential for performance and sustainability. Additionally, we'll delve into the benefits of using a frequency drive motor, discuss its applications, and provide guidance on how to select the most appropriate frequency drive motor for your specific needs.

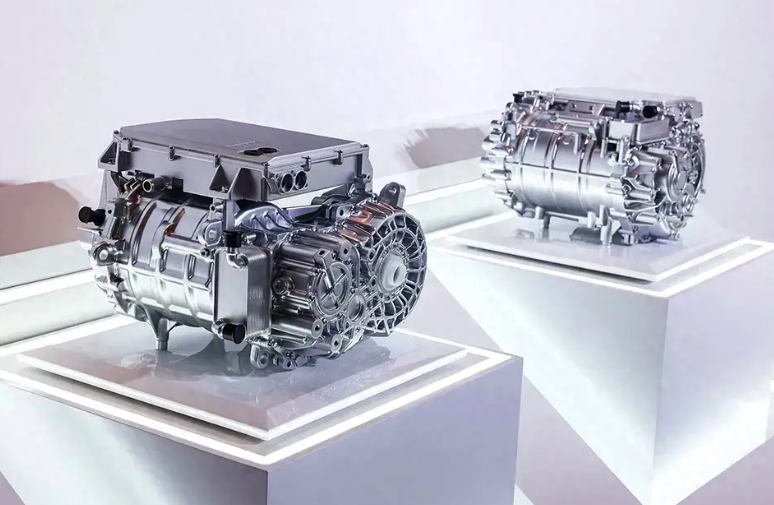

What Is a Motor VFD Drive?

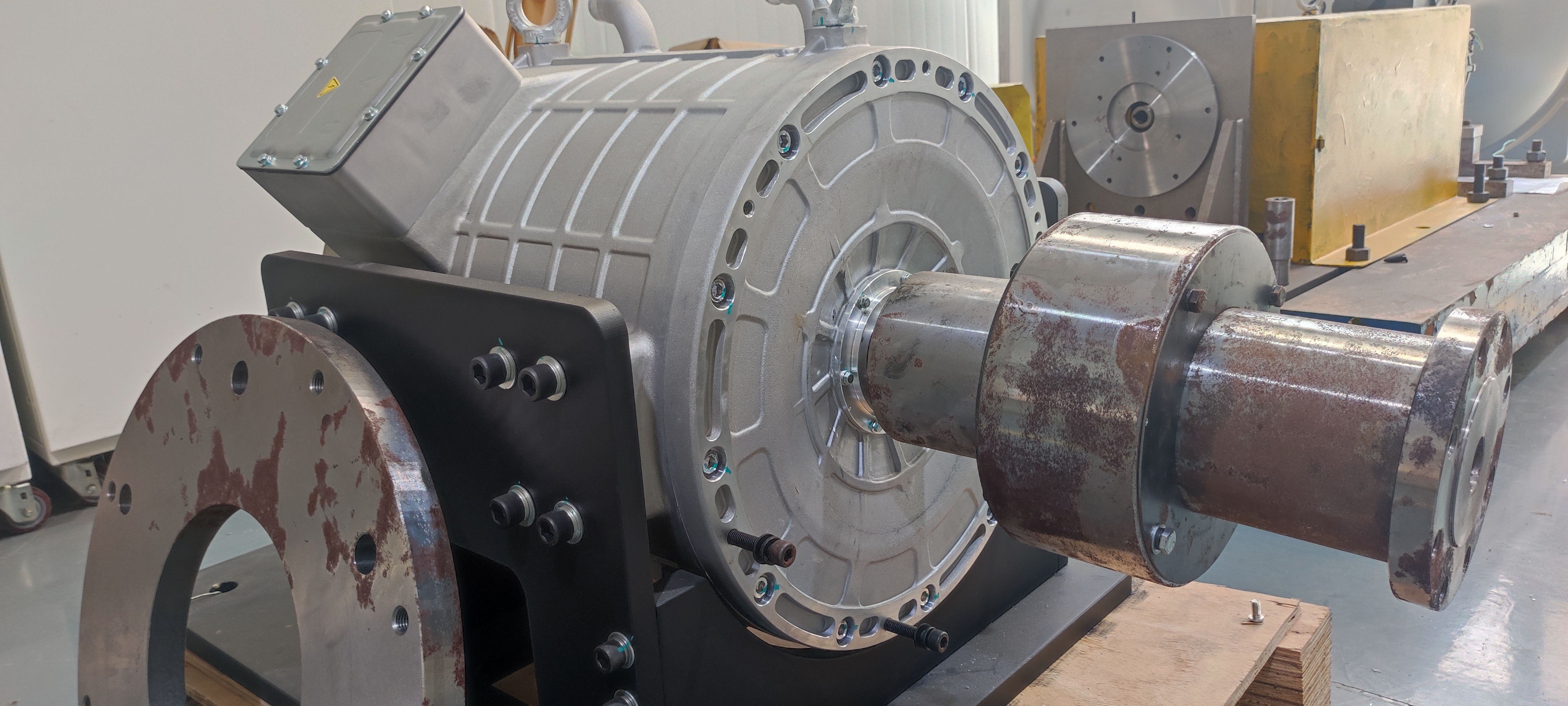

A Motor VFD Drive is an advanced electronic system used to control the speed, torque, and direction of an electric motor. By regulating the frequency and voltage of the power supplied to the motor, the VFD enables precise control over motor performance. This technology is widely utilized across various industries, including in electric vehicles, where optimal motor performance is crucial for maximizing driving range, efficiency, and overall vehicle performance.

Components of a Motor VFD Drive:

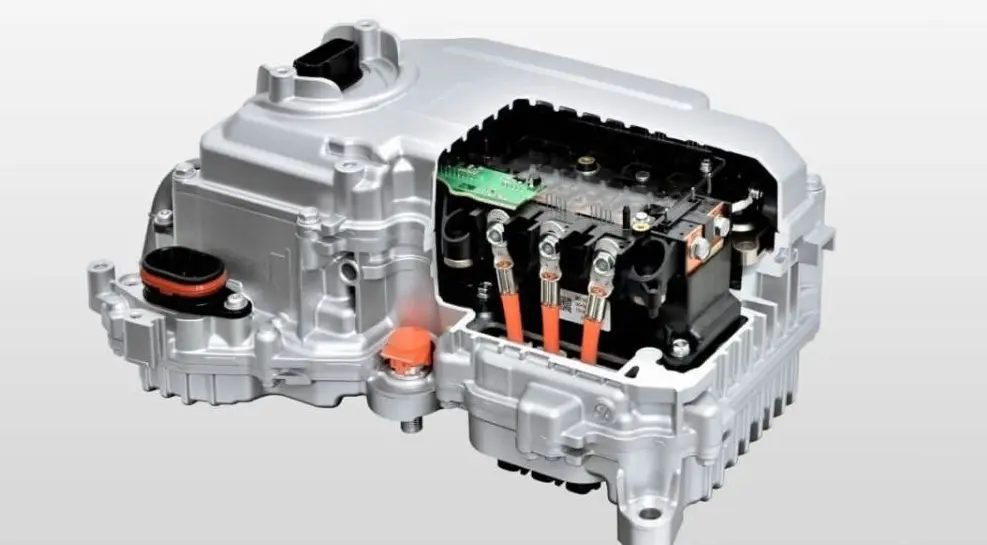

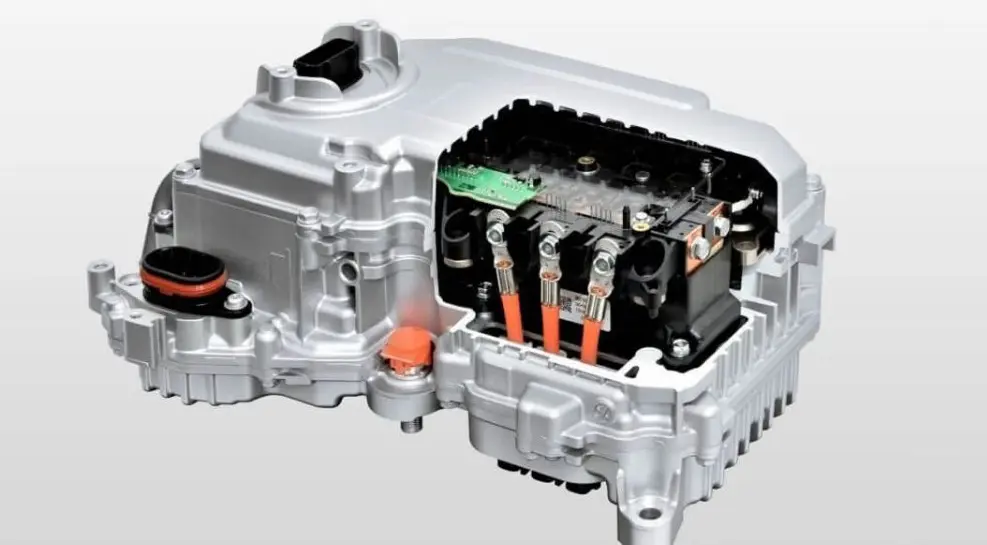

- Rectifier: The rectifier is the first component of a VFD. It converts alternating current (AC) power, which is the type of power most electrical grids provide, into direct current (DC). This process ensures that the system can store energy in a usable form before converting it back into AC power.

- DC Bus: The DC bus acts as an intermediary storage unit. It smoothens and stores the DC power coming from the rectifier, allowing for consistent energy flow to the next stage.

- Inverter: The inverter is responsible for converting the stored DC power back into AC power. The key advantage of this is that the frequency and voltage of the output AC can be adjusted precisely to match the motor’s requirements. By varying the frequency of the AC supply, the VFD can control the speed of the motor.

The ability to adjust the frequency and voltage makes the frequency drive motor incredibly versatile and efficient. In an electric vehicle, the VFD can adjust the motor's speed in response to the driver’s inputs, providing a smooth and efficient driving experience.

Types of Motor VFD Drives

There are several types of frequency drive motors, each with different applications and advantages depending on the specific needs of the system. In the context of electric vehicles, selecting the right type of VFD is crucial to optimize performance and energy efficiency. Here, we’ll explore the main types of VFDs used in various applications, including EVs:

1. Voltage Source Inverter (VSI) VFD

- Overview: VSI VFDs are the most common type of drive used for controlling electric motors in industrial and automotive applications, including electric vehicles. They are designed to provide a controlled output by varying the voltage and frequency supplied to the motor.

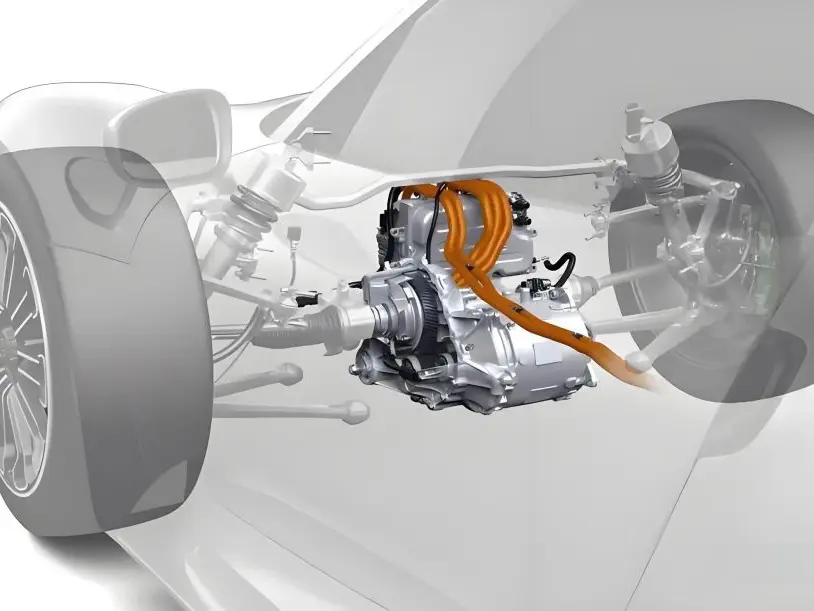

- Application in EVs: VSI VFDs are ideal for electric vehicles because they allow precise control of motor speed, resulting in smooth acceleration, deceleration, and overall better driving dynamics.

- Advantages: They are cost-effective, efficient, and widely available, making them a go-to solution for electric vehicle manufacturers.

2. Current Source Inverter (CSI) VFD

- Overview: In a CSI VFD, the focus is on controlling the current rather than the voltage. This type of VFD is less common in consumer electric vehicles but can be used in certain specialized applications that require high starting torque or steady operation under variable loads.

- Application in EVs: While not the primary choice for most electric vehicles, CSI VFDs may be used in industrial-grade EVs or specialized vehicles requiring very high torque and controlled current for their motors.

- Advantages: Provides high performance under heavy load conditions and is particularly suitable for high-torque applications.

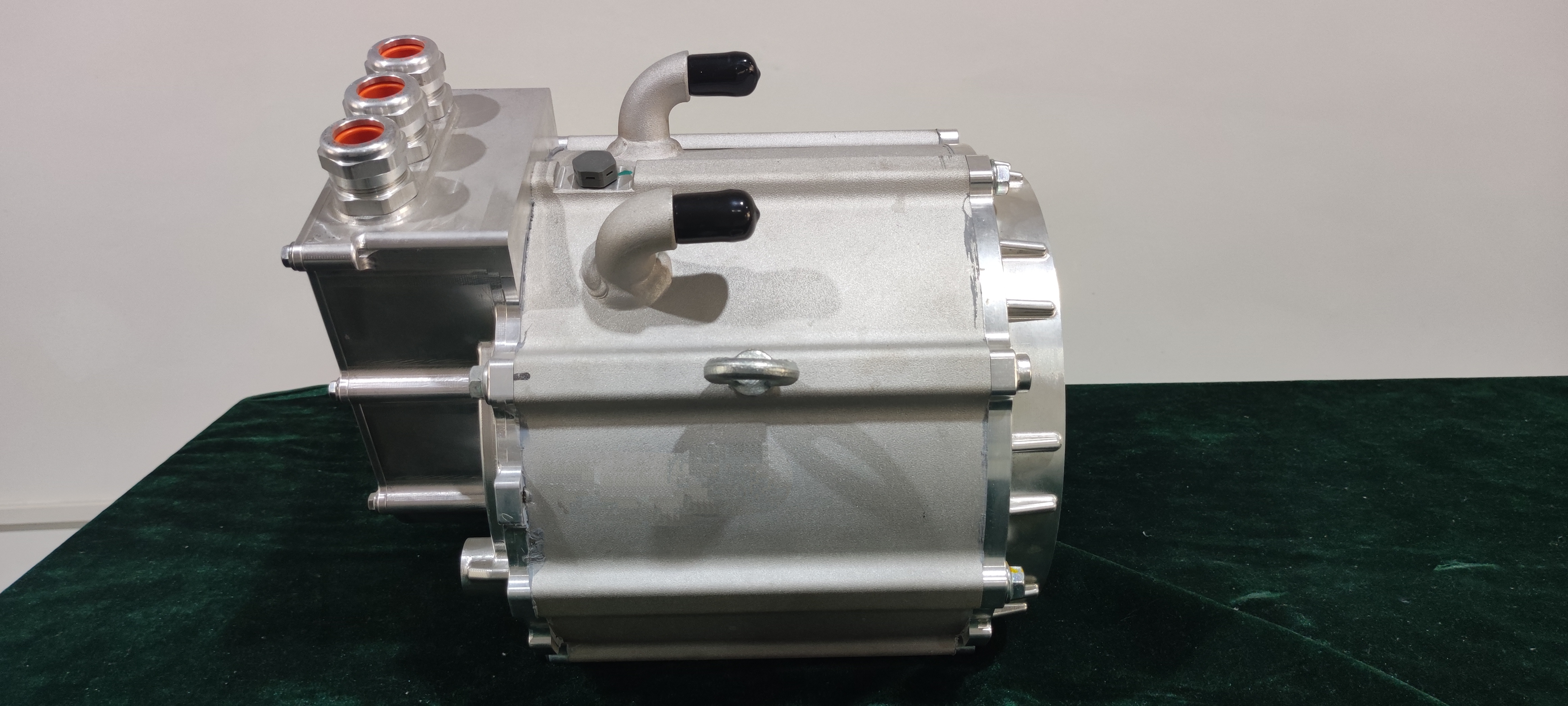

3. Pulse Width Modulation (PWM) VFD

- Overview: PWM VFDs use high-frequency switching to generate an output waveform that controls the motor speed and torque. This type of VFD is widely used because it offers a high degree of precision and efficiency.

- Application in EVs: PWM VFDs are ideal for EVs because they can produce a smooth, continuous power output that reduces power loss and motor heat, contributing to better overall efficiency and longevity.

- Advantages: High efficiency, smooth operation, and minimal energy waste. PWM VFDs are often the best choice for EV applications.

4. Regenerative VFD

- Overview: Regenerative VFDs capture energy that would normally be wasted during braking and convert it back into usable power. This energy is fed back into the battery, effectively recharging it and improving overall energy efficiency.

- Application in EVs: Regenerative VFDs are especially beneficial in electric vehicles, as they enable regenerative braking. This technology helps improve the driving range and reduces the frequency of battery charging.

- Advantages: Energy recovery, enhanced driving range, and a reduced need for frequent charging.

Each of these VFD types offers distinct advantages depending on the needs of the electric vehicle. However, for most consumer and commercial electric vehicles, PWM VFDs are the most commonly used due to their high efficiency and smooth performance.

How Does a VFD Drive Benefit Motor Performance?

Integrating a frequency drive motor into an electric vehicle system brings several critical benefits that help improve motor performance, energy efficiency, and the overall driving experience. These advantages are crucial for extending the lifespan of the motor, reducing maintenance needs, and optimizing performance. Here’s how a VFD drive directly impacts motor operation:

1. Improved Speed Control

A primary benefit of a motor VFD drive is the ability to control the speed of the motor with high precision. In an electric vehicle, the VFD adjusts the frequency of the electrical supply to the motor, directly influencing its speed. This enables smooth acceleration, deceleration, and fine-tuned control over the vehicle’s driving dynamics.

- Why it matters: Smooth speed control enhances the driving experience by eliminating abrupt changes in speed that can be uncomfortable or inefficient.

2. Enhanced Torque Control

Torque is the force that allows the motor to move the vehicle, and the VFD offers enhanced control over torque at various speeds. By adjusting both the voltage and frequency, the motor VFD drive ensures that the motor generates the right amount of torque based on real-time conditions such as load, speed, and road incline.

- Why it matters: This is essential for maintaining efficient performance in various driving conditions, such as accelerating on an incline or during heavy load conditions like towing.

3. Energy Efficiency

VFDs can reduce energy consumption by 20% to 50% depending on the application and motor usage. In the case of electric vehicles, the efficiency improvement from using VFD drives directly translates into improved driving range and reduced battery wear. Traditional motor controllers often operate motors at full speed, regardless of the actual demand. A VFD drive ensures that the motor operates only at the required speed and torque for the given task, significantly reducing energy waste.

- Why it matters: This can directly improve the range of an electric vehicle by reducing energy consumption and maximizing the use of available battery power.

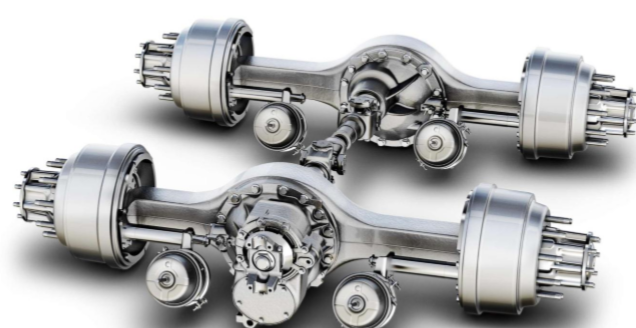

4. Reduced Mechanical Stress

A motor VFD drive allows for soft starts and stops, which reduces the mechanical stress on both the motor and other components in the drive system. This reduces the wear and tear on parts such as the motor windings, bearings, and transmission, contributing to a longer operational lifespan.

- Why it matters: Less mechanical stress translates to reduced maintenance costs and improved reliability of the vehicle over time.

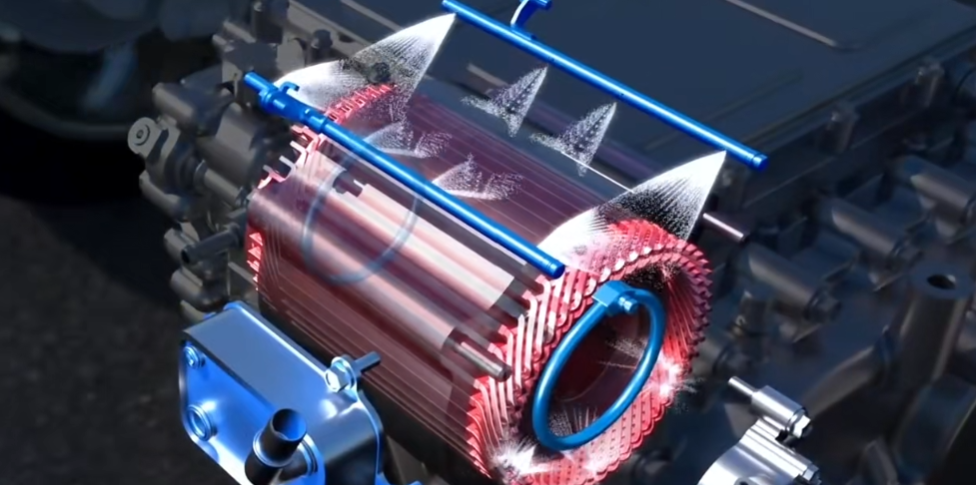

5. Regenerative Braking

Regenerative braking is one of the most notable benefits of integrating a motor VFD drive into an EV. n electric vehicles, regenerative braking systems, enabled by VFDs, can recover up to 30% of the energy typically lost during braking, feeding it back into the battery. The VFD enables the motor to act as a generator during braking, converting the vehicle's kinetic energy back into electrical energy and feeding it back into the battery.

- Why it matters: This feature helps extend the vehicle's range by recovering energy that would otherwise be lost as heat during braking.

Why Do You Need a VFD Drive?

The need for a motor VFD drive in an electric vehicle is driven by several factors, each contributing to the vehicle’s overall performance, efficiency, and longevity. Here are the main reasons why you should incorporate a VFD drive into your electric vehicle system:

1. Energy Savings

By regulating the motor's speed to match the specific needs of the driving conditions, the motor VFD drive minimizes energy waste and improves overall efficiency. This can translate into a longer driving range for electric vehicles and reduced energy consumption, which is particularly important as EV adoption grows.

2. Cost Efficiency

The initial cost of a frequency drive motor may seem high, but the long-term savings far outweigh the upfront investment. The efficiency gains and longer lifespan of the motor reduce operational costs, while regenerative braking contributes to reduced battery charging needs.

Why it matters: Lower operating costs make electric vehicles more affordable over the long term, even if the upfront investment is higher.

3. Better Control and Performance

Whether the vehicle is cruising at high speeds or navigating stop-and-go traffic, the VFD drive provides precise control over motor speed and torque. This translates to a more responsive and dynamic driving experience.

- Why it matters: Superior driving dynamics enhance driver satisfaction and improve vehicle performance across various driving conditions.

4. Environmentally Friendly

By optimizing the efficiency of the motor and reducing energy consumption, the motor VFD drive helps reduce the overall carbon footprint of the vehicle. It ensures that the electric vehicle performs at its peak while consuming less energy from the battery, which in turn reduces the overall environmental impact.

- Why it matters: A smaller carbon footprint is a key consideration for environmentally conscious consumers.

Common Applications of Motor VFD Drives

Motor VFD drives are utilized in a wide range of industries, and electric vehicles are one of the most common applications. Below are a few other common uses:

- Industrial Manufacturing: VFDs are often used in factories to control the speed of motors driving machinery such as conveyor belts, pumps, and compressors.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, VFDs regulate fan speeds, which allows for more energy-efficient climate control.

- Pumps and Fans: In water treatment plants, VFDs control the speed of pumps and fans, improving efficiency and reducing energy consumption.

How to Choose the Right VFD Drive for Your Application

Selecting the right motor VFD drive for your electric vehicle or any other application depends on several factors, including motor specifications, power requirements, and desired performance features. Here are some tips for making the right choice:

- Understand Your Motor Requirements: Determine the power, torque, and speed requirements of your motor system to ensure compatibility with the VFD drive.

- Consider Environmental Conditions: If the motor will operate in harsh conditions (e.g., extreme temperatures, humidity), choose a VFD that can withstand these environments.

- Evaluate Features: Look for features such as regenerative braking, energy-saving modes, and precise speed control that will benefit your application.

Conclusion

Incorporating a motor VFD drive into your electric vehicle or other motor-driven applications is crucial for maximizing performance, enhancing energy efficiency, and reducing operational costs. The frequency drive motor system ensures that your motor operates smoothly across a wide range of conditions while contributing to the longevity and reliability of your equipment. Whether you’re looking to improve an existing system or invest in a new electric vehicle, understanding the role of motor VFD drives is key to making informed decisions that benefit both the environment and your bottom line.

Read More: VCU in Electric Vehicles: The Brain Behind Energy Management and Power Distribution