What Is The Difference Between An EV Drivetrain And Powertrain In Electric Vehicle?

While the terms powertrain and drivetrain are frequently used interchangeably, they actually refer to different systems, each with its own functions. This article explores the role of each within electric vehicles (EVs), outlines their main components, and explains how they interact. It also covers key design factors and offers a glimpse into future innovations.

Powertrain: The core of EV propulsion

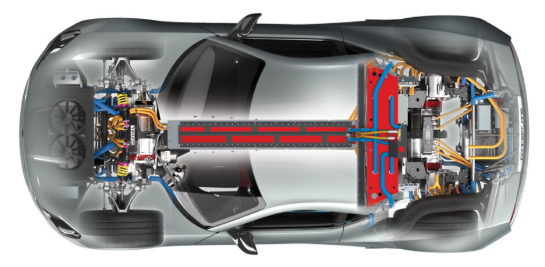

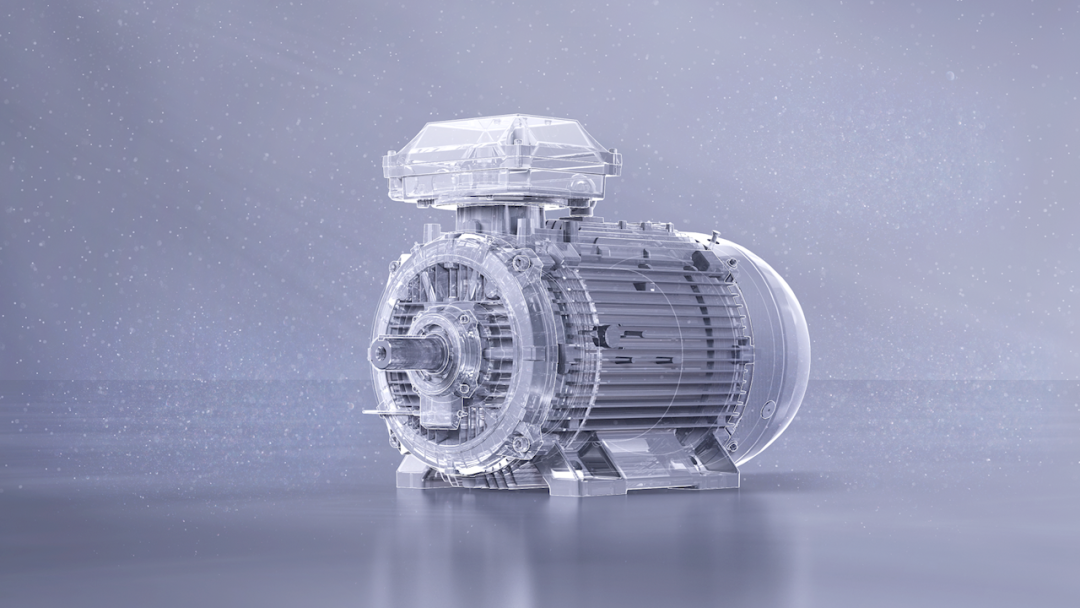

The EV powertrain is responsible for controlling and supplying electrical energy, converting it into mechanical force through a cohesive set of components. Central to this system are electric motors, which generate magnetic fields in their stator windings to rotate the rotor and propel the vehicle. These motors also enable regenerative braking by reversing their function, converting motion back into stored electricity.

Another critical element is the battery traction pack, which consists of numerous lithium-ion cells and an integrated battery management system (BMS). The BMS ensures proper operation by regulating regenerative braking, maintaining ideal voltage, temperature, and capacity levels.

EV powertrains also include:

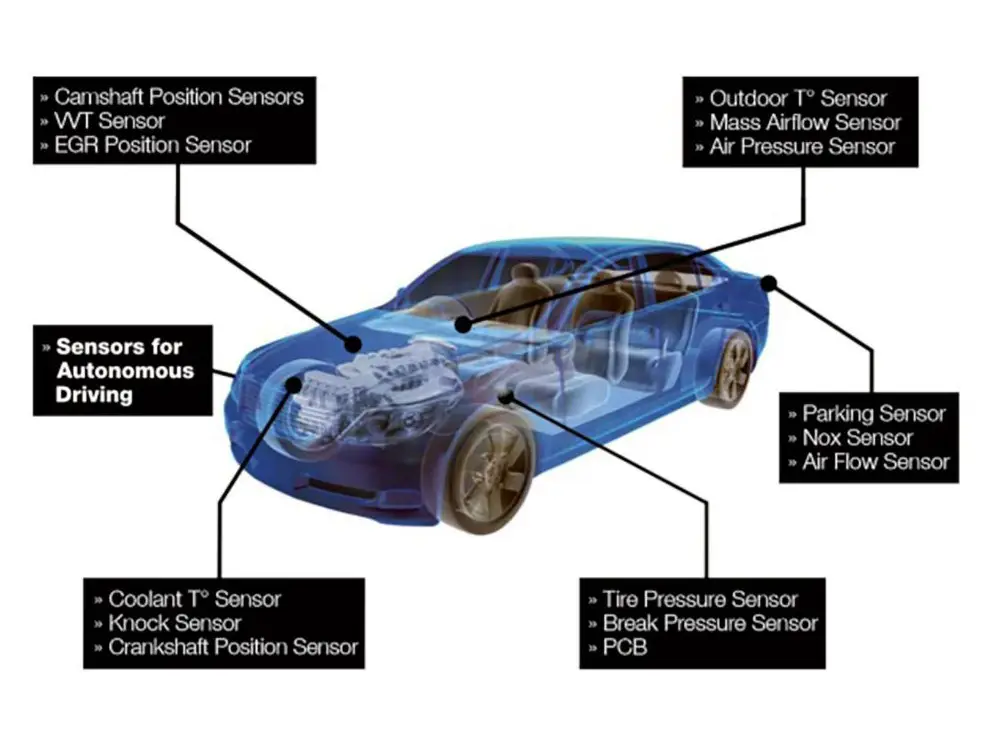

- Vehicle Control Unit (VCU): Acting as the system’s central processor, the VCU coordinates data from motor controllers, sensors, and the BMS to manage overall performance and advanced functions like regenerative braking and energy efficiency.

- Transmission: Most EVs use a simplified, single-speed transmission with a fixed gear ratio to enhance efficiency and reduce mechanical complexity. In some models, electric motors directly drive the wheels, eliminating the need for a conventional transmission.

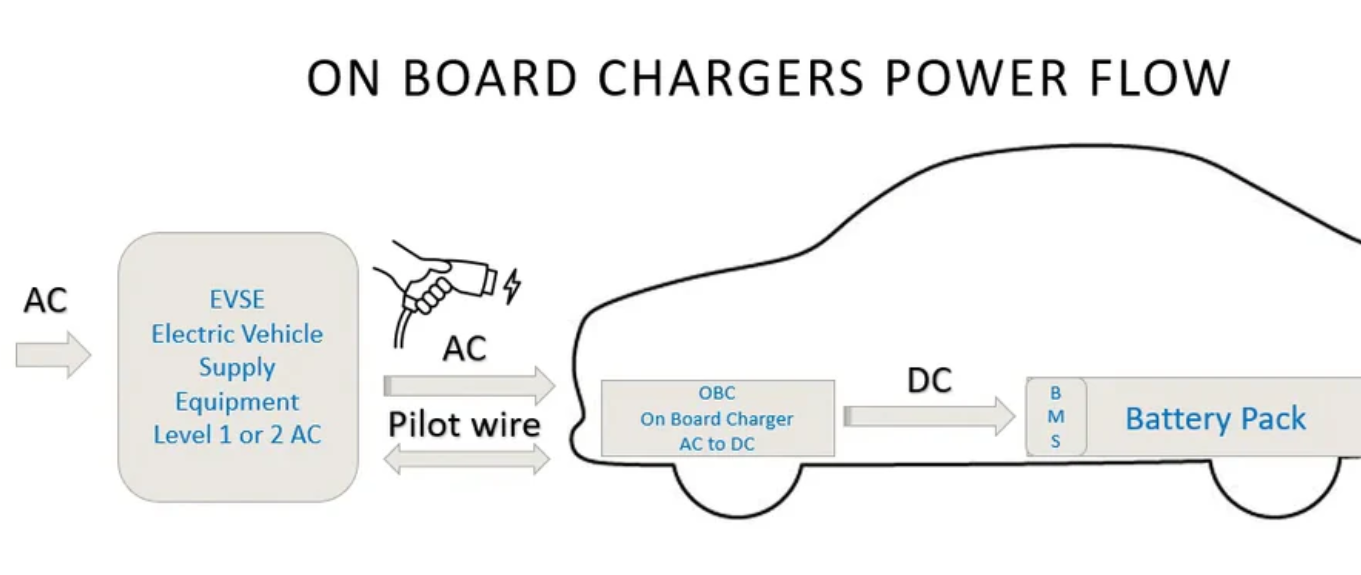

- Power Electronics: These devices, including inverters and converters, control the direction and type of electrical flow — converting battery-supplied DC into AC for motor use and reversing the process during regenerative braking.

- Thermal Management Systems: To ensure optimal performance, these systems use liquid cooling loops, heat exchangers, and smart sensors to regulate temperature and prevent overheating or thermal runaway.

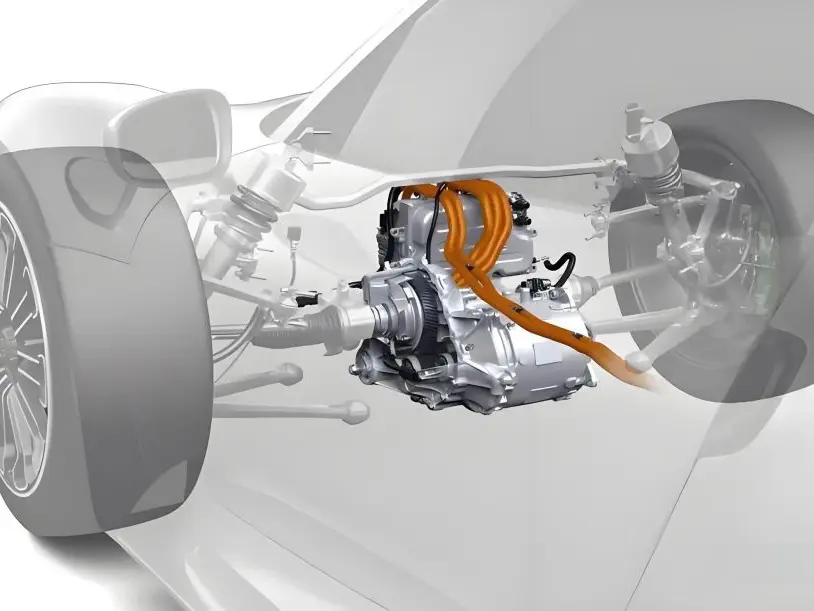

Drivetrain: Translating power into motion

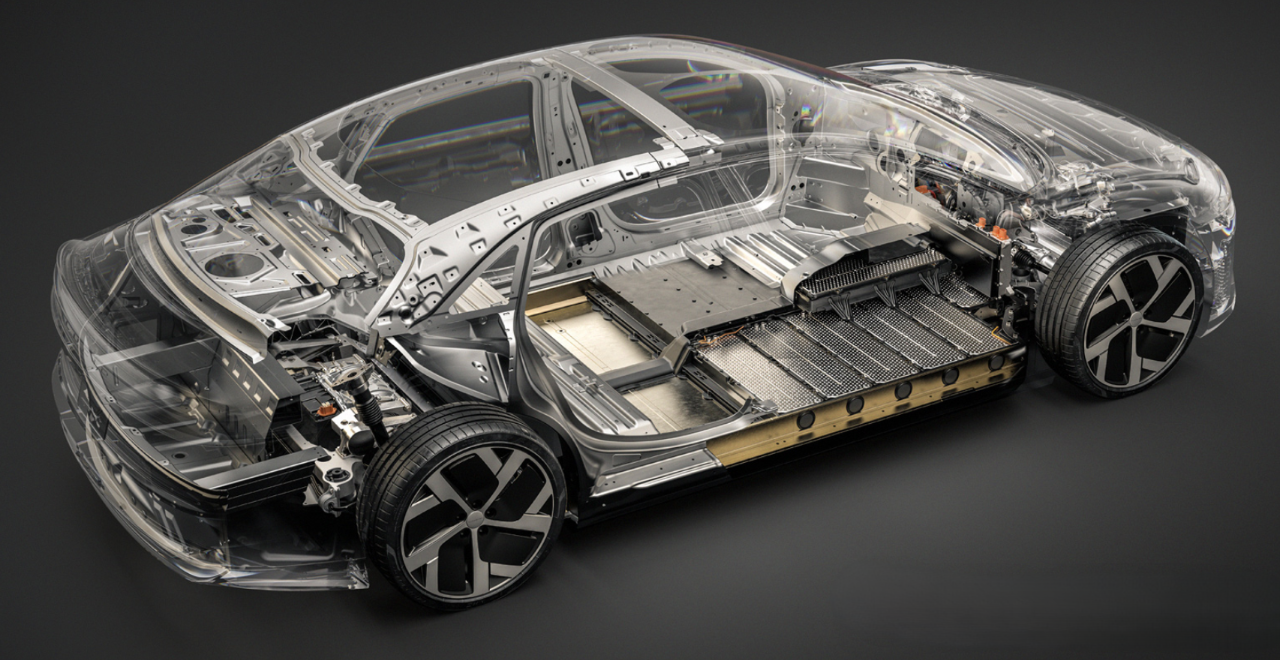

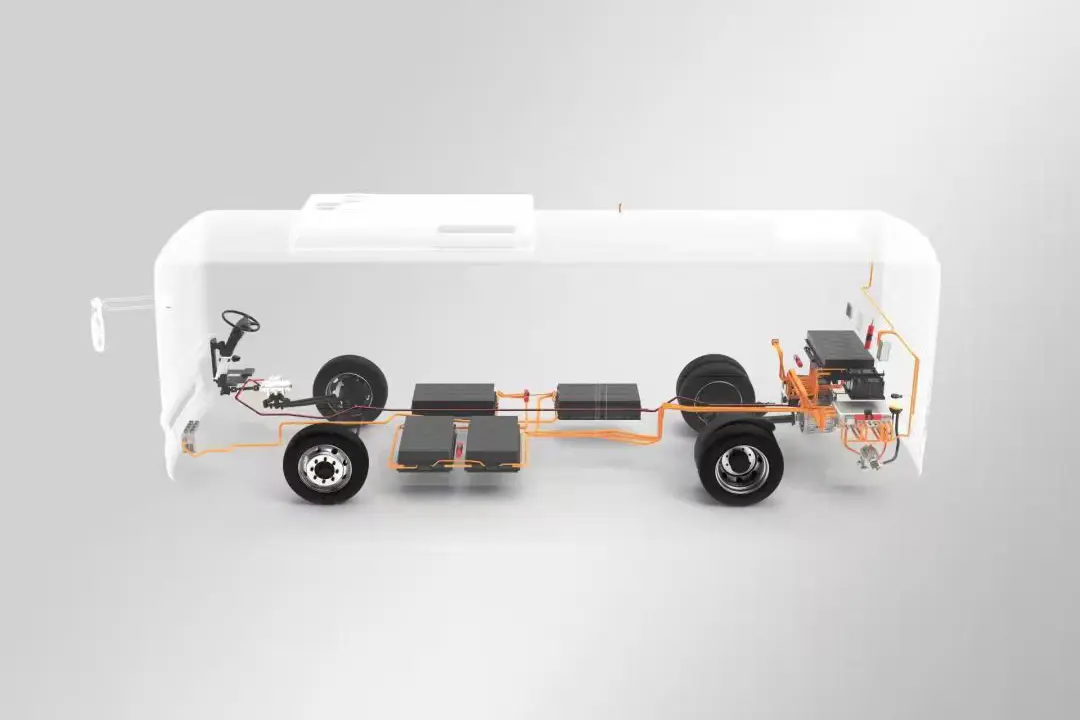

The EV drivetrain plays a key role in channeling power from the electric motors to the wheels with high efficiency. At the core of this system is the transmission, which acts as a bridge between the powertrain and electric vehicle drivetrain, managing torque distribution for optimal performance.

Within the drivetrain, differential gearsets allow each wheel to spin at different speeds, adjusting torque based on wheel load and driving conditions. Drive shafts, which are directly linked to these gearsets, carry the adjusted torque from the transmission to the wheels. This setup ensures smooth and efficient power delivery, especially on slippery, uneven, or wet surfaces.

Axles, another critical part of the drivetrain, support the vehicle’s weight and enable wheel rotation. They also help maintain proper wheel alignment, enhancing traction and improving handling responsiveness. In more advanced EVs, axles may include features like limited-slip differentials or torque-vectoring technologies for better control.

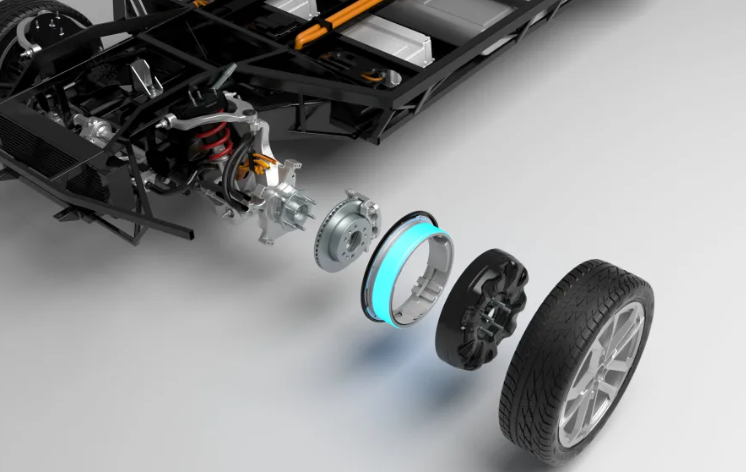

Some electric vehicles go a step further by integrating hub motors directly into each wheel, enabling highly precise torque management and enhanced maneuverability.

Design considerations and challenges

To achieve peak performance in electric vehicles, it’s crucial to adopt an integrated design strategy that harmonizes both the powertrain and drivetrain systems. Coordination between the two is vital, as motor control and energy distribution within the powertrain directly influence the drivetrain’s ability to deliver precise handling, agility, and responsiveness.

Many EVs utilize sophisticated control algorithms to align motor output with real-time torque demands, optimizing both efficiency and driving dynamics.

Thermal management also plays a critical role in maintaining the reliability of powertrain and drivetrain components. Advanced cooling technologies, predictive control systems, and innovative heat-resistant materials help regulate temperatures, reduce wear, and protect vital systems. A well-integrated thermal management strategy not only sustains performance and extends component lifespan but also ensures safety, particularly under high-heat conditions.

The future of EV powertrains and drivetrains

Future electric vehicle (EV) powertrains are expected to deliver greater efficiency in both energy production and management. Innovations like solid-state batteries are on the horizon, offering benefits such as increased energy density, faster charging times, and longer driving ranges. Improvements in power electronics — including next-generation inverters and advanced energy management systems — will further enhance how electricity is converted and distributed within the vehicle.

On the drivetrain side, upcoming advancements are likely to focus on optimizing component design and operational performance. Breakthroughs in materials science are enabling the creation of lighter, stronger drivetrain parts, which help reduce energy losses and boost overall efficiency. Features like advanced electric torque vectoring will provide more precise power distribution to each wheel, enhancing traction and handling, especially in all-wheel-drive setups. Evolving regenerative braking technologies will also improve the recovery and conversion of kinetic energy into usable power.

At the same time, EV designers are moving toward deeper integration of powertrain and drivetrain systems. With the support of AI-driven sensors and machine learning algorithms, EVs will be able to intelligently and dynamically manage power delivery based on real-time driving conditions. This tighter integration will not only extend battery life and improve performance but also lay the groundwork for future autonomous driving systems.

Conclusion

While closely interconnected in operation, EV powertrains and drivetrains are separate systems, each serving unique roles. The powertrain handles the control and delivery of electrical energy, converting it into mechanical force through a coordinated set of components. In contrast, the drivetrain is tasked with transmitting that mechanical power from the electric motors to the wheels.

Read More: Why We Use EV DC/DC Converter in Electric Vehicles