The Future of Electric Cars: Will high voltage systems become a new standard?

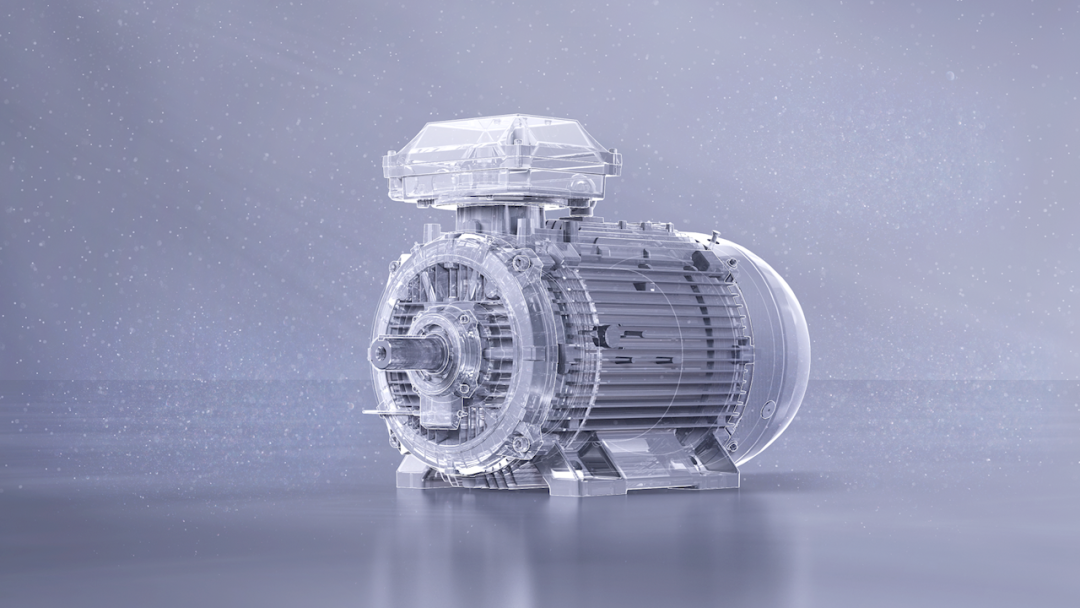

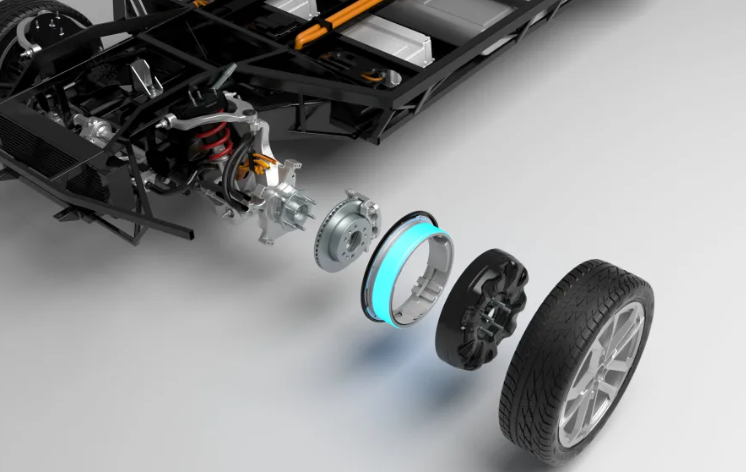

The electric drive system can be regarded as the hub of energy conversion, and its main role is to convert the electrical energy in the battery pack, into mechanical energy that drives the vehicle forward.

01.General

Electric drives are drive that use electricity as an energy source. Electricity is a clean, efficient and renewable source of energy that can be used to drive a wide range of mechanical equipment and transportation through electric motors or other power conversion devices.

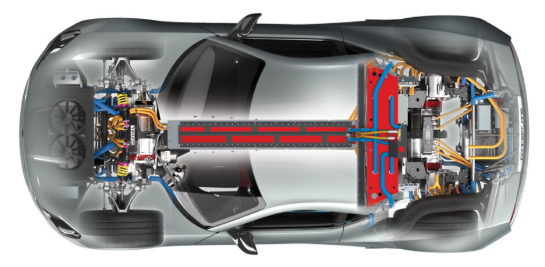

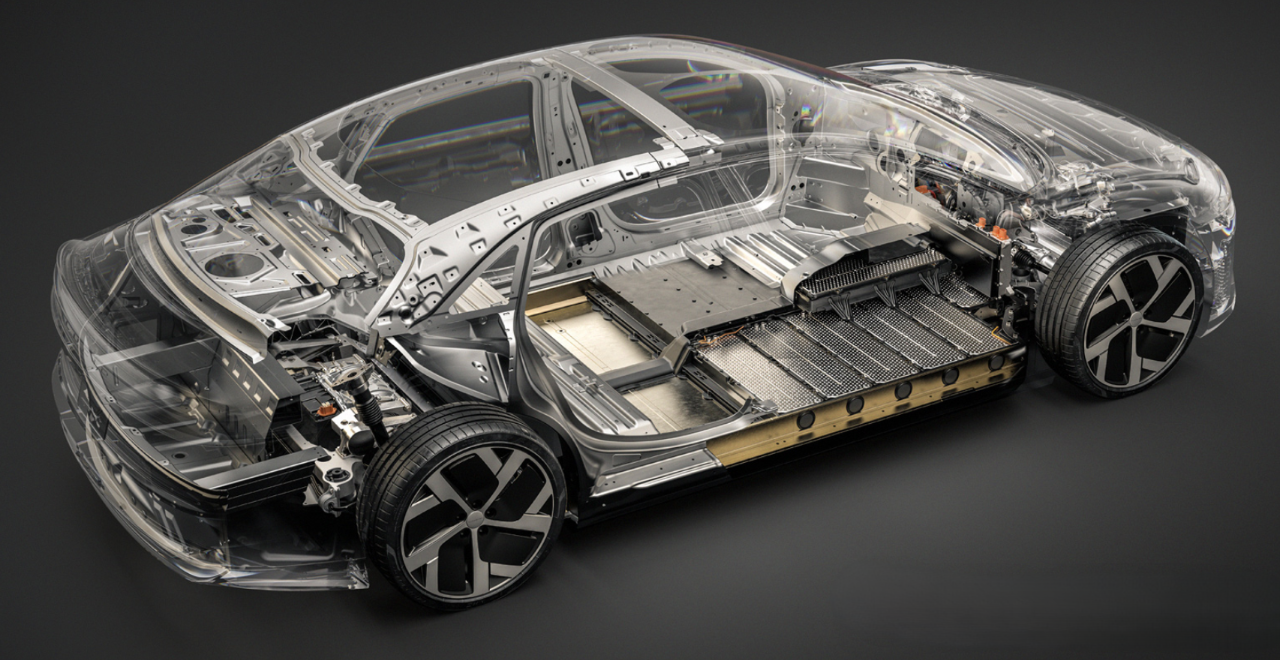

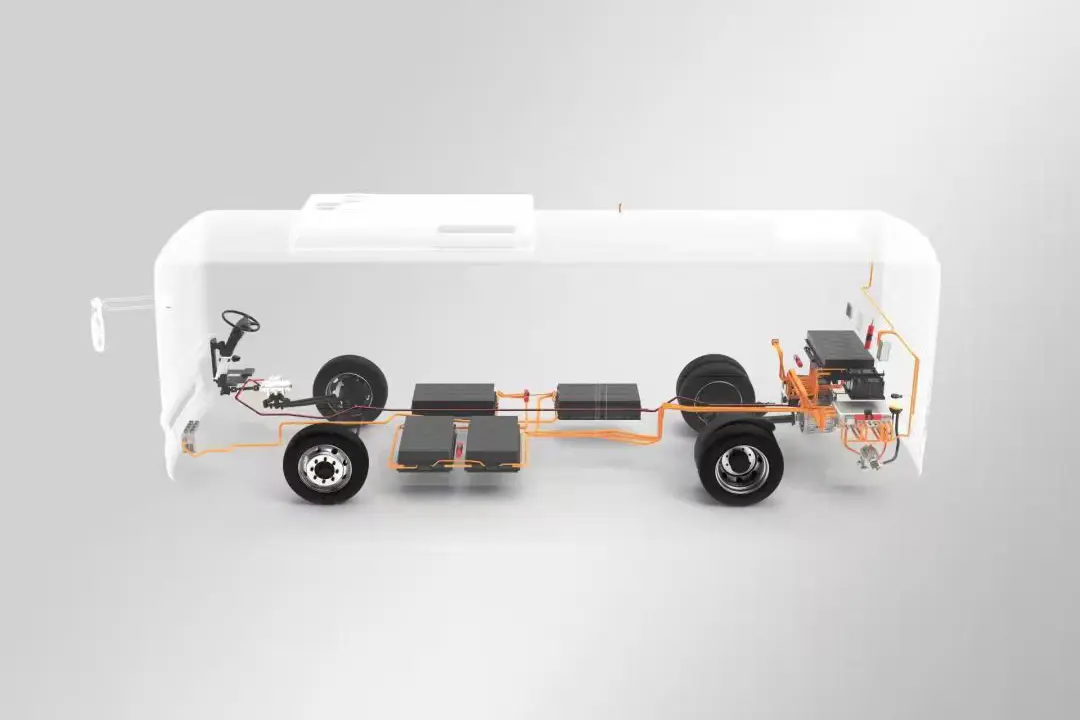

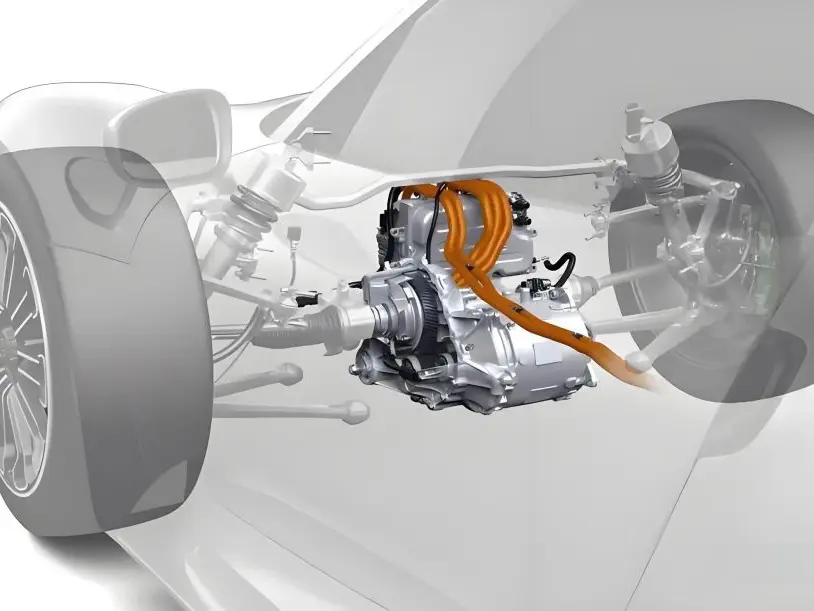

02.System components

(1) Motor: Responsible for converting electrical energy into mechanical energy to provide power.

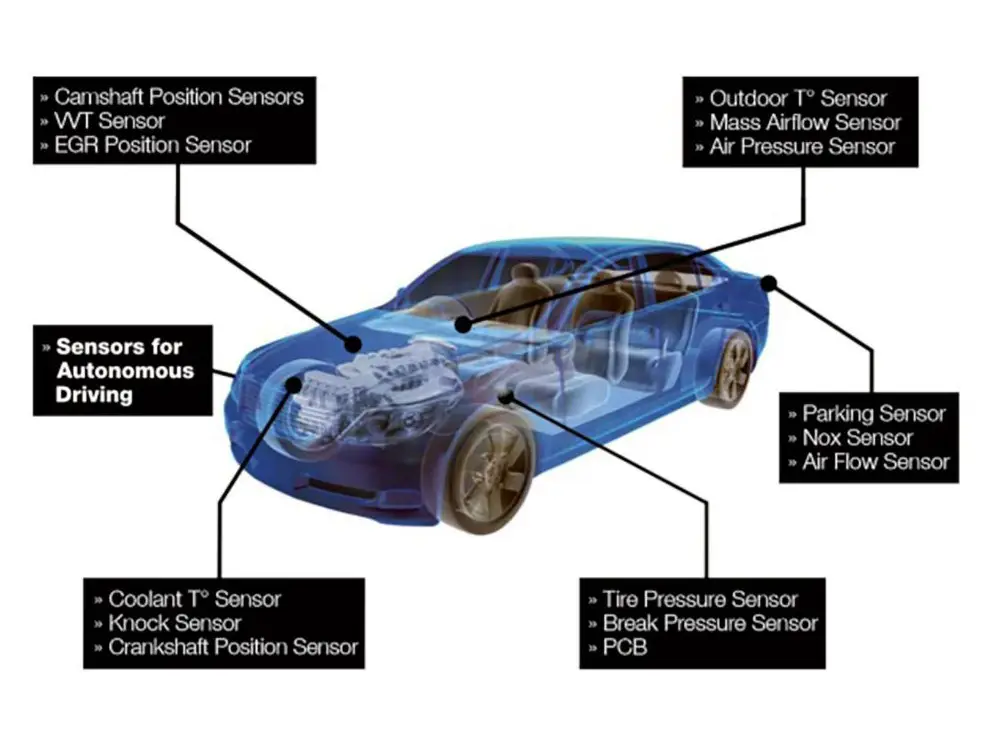

(2) ESC(MCU): Controls the speed and torque of the motor and provides the motor with the appropriate amount of electrical energy.

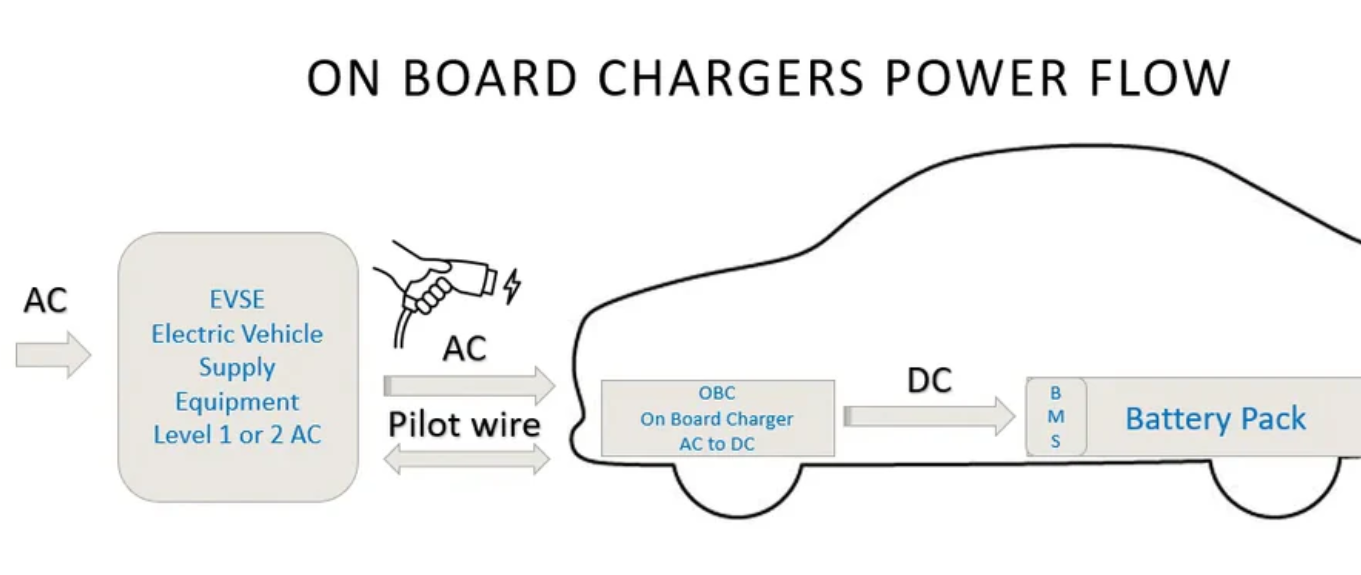

(3) Energy converter: Converts electrical energy into the voltage and current needed to drive the motor.

(4) Energy management system: responsible for managing the energy of the electric drive system to ensure the safety and reliability of energy.

(5) Transmission system: transfer the power of the motor to the wheels to drive the vehicle forward.

(6) Control system (VCU): responsible for controlling the various parts of the electric drive system, so that it coordinates its work to complete the vehicle drive.

PUMBBA is a leading provider of high-efficiency Electric vehicles drive system. We design and manufacture permanent magnet synchronous motors (PMSM), electric vehicle motor controllers (MCU), controllers for electric vehicles (VCU), and electric vehicle power supply systems (DCDC, DCAC,OBC, PDU), tailored for a wide array of commercial electric vehicles. Creating an integrated solution for electric vehicle drive platforms that meet various usage needs.

03.Advantages of electric drives

(1) High energy conversion efficiency: the electric drive system generates force and torque directly through the electric motor, eliminating the intermediate energy conversion process, so it has a high energy conversion efficiency.

(2) Environmental characteristics: electric drive system is pollution-free, zero emission, friendly to the environment, help reduce the damage to natural resources.

(3) Flexible control of the working state: the electric drive system can conveniently control the working state to adapt to different work requirements.

(4) Unaffected by the external environment: The working state of the electric drive system is stable and will not be affected by changes in the external environment.

(5) Low noise: the electric drive system produces less noise when running, which has less impact on the environment.

(6) High degree of integration: the electric drive axle applied in electric vehicles has the advantages of high degree of integration, small volume and low energy consumption, which plays an important role in improving the power and economy of electric vehicles.

(7) Cost-effectiveness: Although the centralized electric drive axle has a complex structure, it has the advantages of low cost, less influence on the design of transmission system and low development difficulty.

04.Disadvantages of electric drives

(1) Higher cost: Electric drive systems, especially components such as the electric drive train and power battery of electric vehicles, are usually more costly than conventional fuel vehicles.

(2) Complex maintenance: The complexity of electric drive systems leads to higher maintenance difficulties and costs.

(3) High technical requirements: electric drive systems have strict performance requirements for electric motors, which need to maintain good performance under complex working conditions such as frequent starting, stopping, hill climbing, acceleration and deceleration.

(4) Complex chassis structure: Electric motor drives may lead to complex chassis structures, especially in distributed drive systems.

(5) Inefficient transmission: The transmission efficiency of an electric motor drive system may be lower than that of a conventional fuel vehicle.

(6) Complex control: The control of electric motor drive systems may be more complex than that of conventional fuel vehicles.

(7) Susceptibility to interference: voltage-driven electric drive systems have high input impedance and are susceptible to interference from stray electric fields.

(8) Complex mechanical structure: the mechanical structure of the DC motor is more complex, which may lead to instantaneous overload capacity and motor speed increase is limited.

(9) High-frequency electromagnetic interference: motor operation may produce high-frequency electromagnetic interference, affecting the performance of other electrical appliances in the vehicle.

(10) High current demand: In large load situations such as starting, hill climbing, etc., the electric drive system requires large torque and high current, which may cause damage to the battery and permanent magnets.

05.Summary

Currently in the commercial electric vehicles scale continues to expand the background, electric drive system as a core components, its market demand continues to increase, the installed capacity is growing rapidly, the industry has better prospects for development. Domestic electric drive system technology level will continue to upgrade, industry concentration will continue to improve, the future development potential of the industry is huge.