What Is a DC/DC Converter in Electric Vehicles

The global DC/DC converter market for electric vehicles is projected to grow at a CAGR of over 8% from 2023 to 2030, driven by increasing EV adoption and advancements in power electronics. As electric vehicles (EVs) continue to grow in popularity, the demand for efficient and reliable power conversion systems is increasing. One such critical component is the DC/DC converter. This essential part of an EV’s powertrain ensures that energy is efficiently distributed and utilized across various systems, enhancing overall vehicle performance and driving experience. In this blog, we’ll explore the role of the DC/DC converter for electric vehicle systems, how they work, their benefits, challenges, and the technological advancements driving their evolution.

Introduction to DC/DC Converter in Electric Vehicles

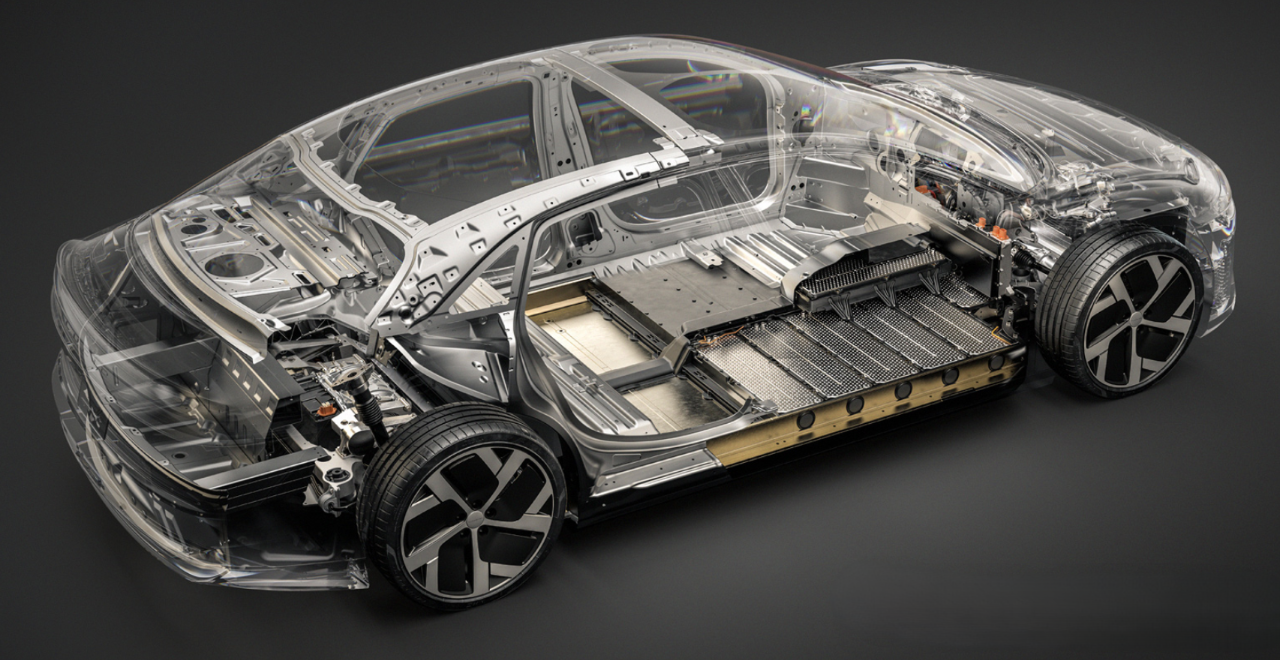

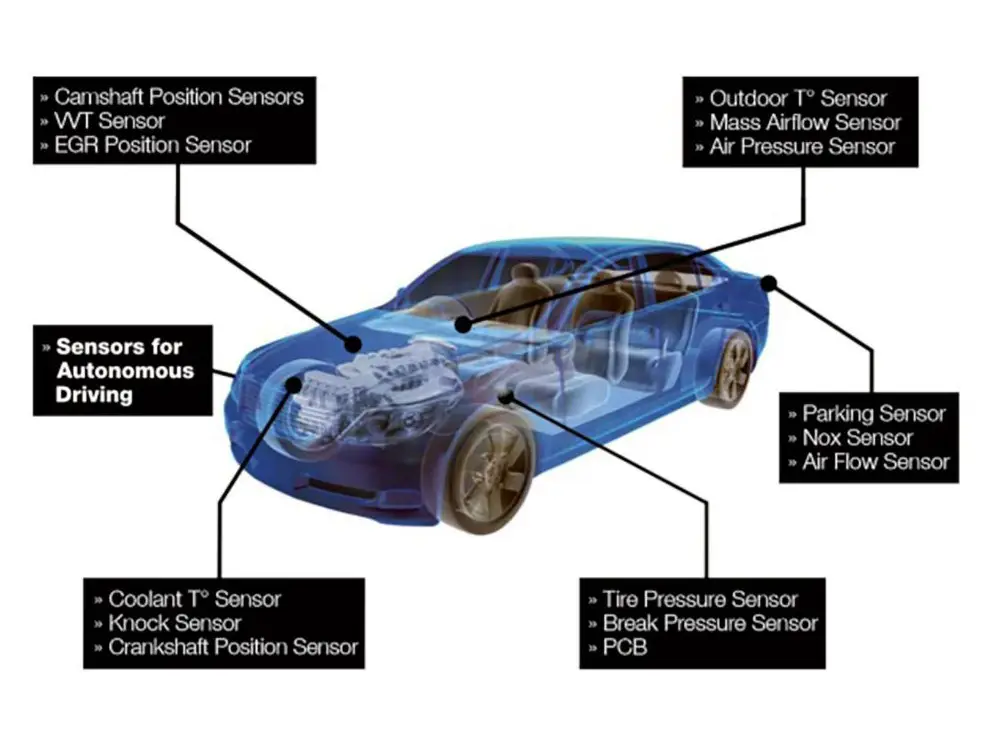

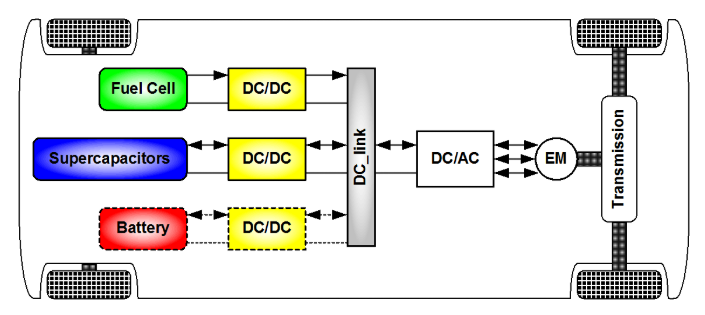

In an electric vehicle, a DC/DC converter in electric vehicles plays a vital role in the management of electrical power. Essentially, a DC/DC converter is an electronic device that changes the voltage level of direct current (DC) from one level to another. The primary purpose of this component in an EV is to manage the power distribution from the high-voltage battery pack to various low-voltage components, such as the electric motor, lights, infotainment system, and safety systems.

Unlike conventional internal combustion engine vehicles, which rely on alternators to generate power for low-voltage systems, electric vehicles depend on DC/DC converters to regulate the power coming from the battery pack, which is typically at a much higher voltage than needed for the low-voltage systems.

These converters ensure that energy is efficiently delivered to all the necessary parts of the vehicle, preventing over-voltage or under-voltage issues that could damage components or cause inefficiencies.

How DC/DC Converters Work in Electric Vehicles

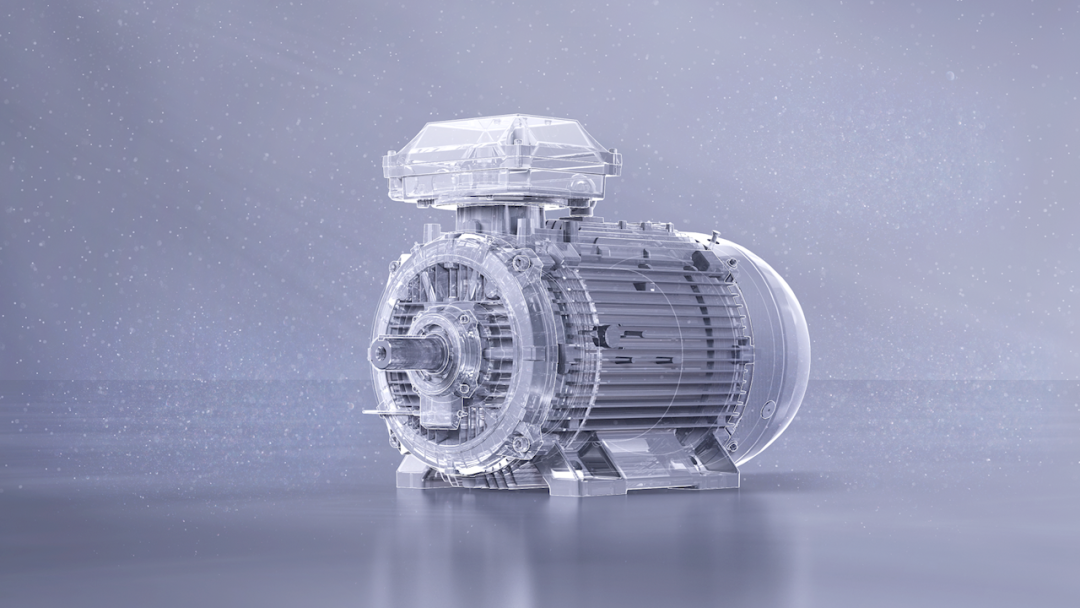

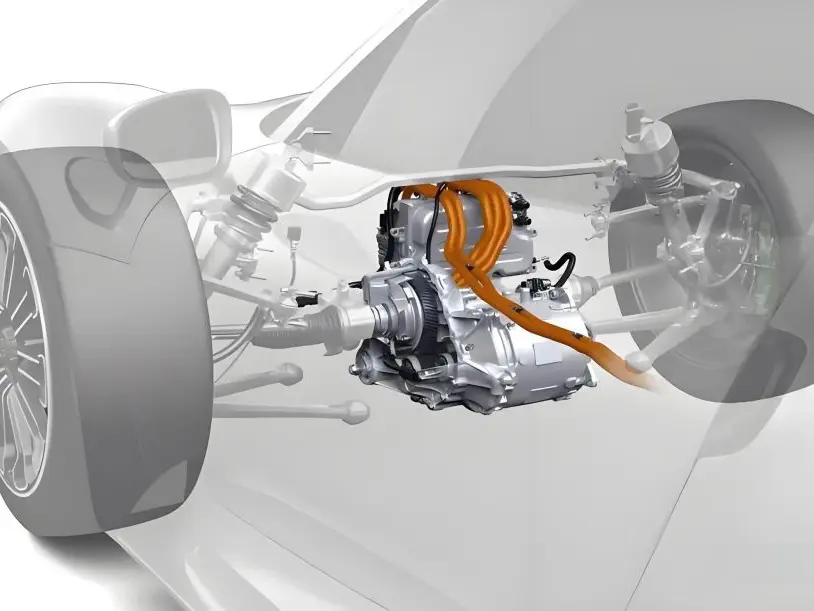

A DC/DC converter for electric vehicle works by stepping down or stepping up the voltage from the battery pack to suit the needs of different systems within the vehicle. This conversion process is achieved through the use of inductors, capacitors, and semiconductor switches, which together create a regulated output voltage.

The most common types of DC/DC converters used in electric vehicles are buck converters, which step down the voltage, and boost converters, which step it up.

- Buck Converters: These are used when the vehicle's systems require a lower voltage than the battery pack provides. For example, a typical EV battery may operate at 300-400 volts, but many systems, such as the onboard electronics and control units, require a much lower voltage, such as 12 or 48 volts. The buck converter efficiently reduces the high voltage to the required level without wasting energy in the process.

- Boost Converters: In some cases, a boost converter may be needed when a higher voltage is required for specific components. For instance, in hybrid electric vehicles (HEVs) or plug-in hybrid electric vehicles (PHEVs), the vehicle may need to step up the voltage for certain systems or even during regenerative braking when power is being returned to the battery.

- Buck-Boost Converters: These are hybrid devices that can either step up or step down the voltage, providing a flexible solution for a range of electrical requirements.

By constantly adjusting the voltage levels, the DC/DC converter ensures that the vehicle operates efficiently and that all systems receive the proper amount of power.

Types of DC/DC Converters Used in Electric Vehicles

There are several types of DC/DC converters used in electric vehicles, each suited to different applications within the vehicle's electrical system. Below are some of the key types:

- Isolated DC/DC Converters: These converters offer electrical isolation between the input and output, which is crucial for safety in high-voltage applications. They are often used in EVs for systems that require isolation, such as for charging or powertrain control systems.

- Non-Isolated DC/DC Converters: These are commonly used for lower-voltage applications, where isolation is not necessary. They are more efficient and simpler to design but are typically used in applications like powering 12V systems or inverters.

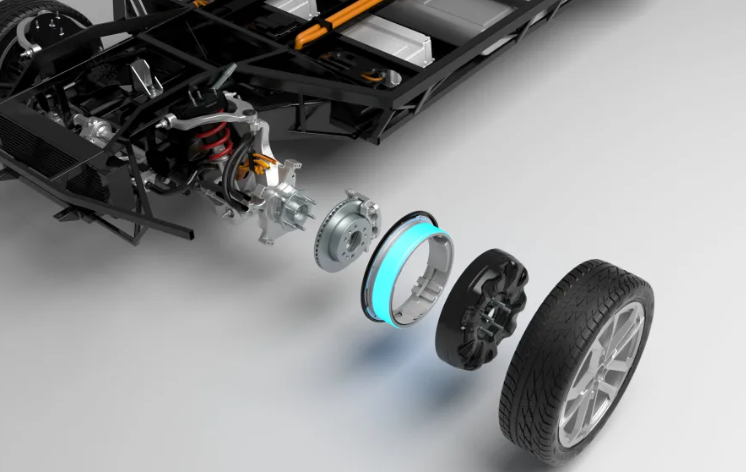

- Bidirectional DC/DC Converters: In some advanced EVs, bidirectional converters are used, which allow energy to flow in both directions. This is especially useful for vehicle-to-grid (V2G) applications, where the vehicle can supply power back to the grid or to other devices.

- Digital DC/DC Converters: With advancements in technology, digital control has been integrated into DC/DC converters, providing better efficiency, reduced size, and enhanced performance. These converters are capable of adjusting their operation in real-time based on changing conditions, optimizing the energy conversion process.

The Role of DC/DC Converter in Electric Vehicle Powertrains

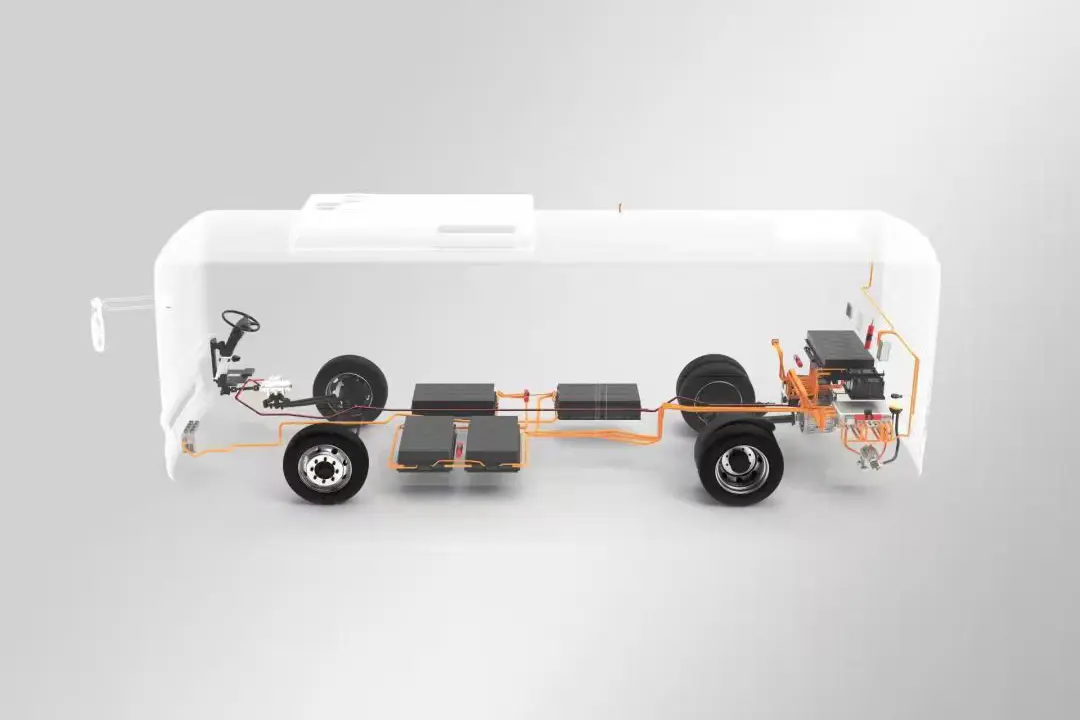

The DC/DC converter in electric vehicles is a critical component of the vehicle’s powertrain, ensuring that the power generated by the high-voltage battery pack is efficiently distributed to various systems throughout the vehicle.

The main role of the DC/DC converter in this context is to step down the voltage from the battery to the appropriate level required by different systems, such as the motor controller, lighting, air conditioning, and the vehicle's low-voltage electrical systems.

In addition to providing the necessary voltage for these systems, DC/DC converters also contribute to the overall energy efficiency of the vehicle. By ensuring that power is used efficiently, they help reduce energy waste and maximize the range of the electric vehicle.

Key Benefits of DC/DC Converter in Electric Vehicles

The integration of DC/DC converter in electric vehicles offers several key benefits:

- Energy Efficiency: Modern DC/DC converters for EVs achieve efficiency rates of 90-96%, minimizing energy loss and improving battery performance. One of the most significant advantages of DC/DC converters is their ability to efficiently convert high-voltage power from the battery to the necessary voltage levels for the vehicle’s systems. This reduces energy losses, improves battery range, and ensures that the vehicle runs more efficiently.

- Compact Design: DC/DC converters allow for a more compact design of the vehicle’s powertrain, as they can be smaller and lighter than other types of power distribution systems. This leads to reduced overall vehicle weight, contributing to improved performance and efficiency.

- Cost Savings: By enabling efficient power conversion, DC/DC converters help reduce the overall cost of operating an electric vehicle. They optimize energy usage, which can lead to fewer charging cycles and less frequent maintenance of high-voltage systems.

- Safety: DC/DC converters provide electrical isolation, which is crucial for the safety of both the vehicle and its passengers. By preventing potential electrical faults and short circuits, they ensure that the high-voltage systems remain safe and stable.

- Enhanced System Integration: The versatility of DC/DC converters allows them to be integrated into various parts of the EV’s powertrain, including the onboard charging system, auxiliary power units, and power management systems. This integration leads to a more seamless and efficient overall system.

Challenges in DC/DC Converter Design for Electric Vehicles

Despite their advantages, there are several challenges involved in the design and integration of DC/DC converter for electric vehicles:

- Efficiency and Heat Management: As DC/DC converters are responsible for significant energy conversion, managing the heat generated during operation is crucial. Inefficiencies in conversion can lead to excessive heat, which can affect the performance and longevity of the converter. Designers must focus on creating converters with high efficiency and effective thermal management systems.

- Size and Weight Constraints: While DC/DC converters help reduce the size and weight of the powertrain, they themselves need to be compact without compromising on performance. Balancing size, weight, and power output remains a challenge for engineers.

- Cost of Advanced Materials: Some of the more efficient DC/DC converters require expensive materials such as wide-bandgap semiconductors. These materials can increase the cost of the converter, which may impact the overall affordability of electric vehicles.

- Integration with Other Power Systems: DC/DC converters need to work seamlessly with other power systems within the vehicle, such as inverters, battery management systems, and motor controllers. Ensuring compatibility and smooth integration is often a complex process.

DC/DC Converters in EV Charging Systems

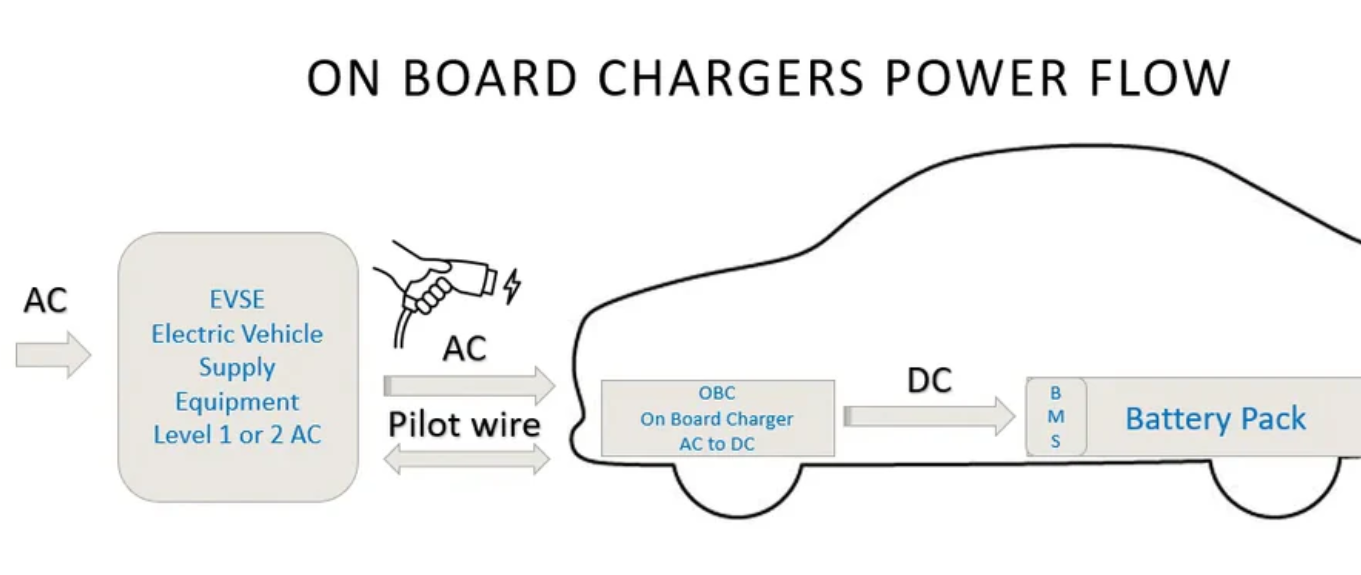

DC/DC converters also play an essential role in EV charging systems. When an electric vehicle is plugged into a charging station, the charging system needs to convert the alternating current (AC) from the grid into the direct current (DC) used by the battery. In many cases, DC/DC converters are used to regulate and optimize this conversion process.

Moreover, as the EV charging infrastructure evolves, bidirectional DC/DC converters are becoming more prevalent. These converters allow for vehicle-to-grid (V2G) capabilities, where the vehicle can supply power back to the grid or to other electric devices, enhancing the overall efficiency of the charging system.

Technological Advancements in DC/DC Converter for Electric Vehicles

The field of DC/DC converter for electric vehicles has seen significant advancements in recent years. Engineers are continuously working to improve the efficiency, size, and cost-effectiveness of these components. Some of the key technological innovations include:

- Wide-Bandgap Semiconductors: Materials like silicon carbide (SiC) and gallium nitride (GaN) are being increasingly used in DC/DC converters for EVs due to their superior thermal performance and efficiency at high voltages.

- Advanced Control Algorithms: New control strategies and digital systems are being implemented to further optimize the operation of DC/DC converters, allowing them to adapt to real-time driving conditions and battery performance.

- Integrated Power Electronics: Some companies are developing integrated power electronics that combine DC/DC converters with other power management components, further reducing the size and complexity of the powertrain.

Conclusion

In conclusion, DC/DC converter in electric vehicles are a crucial technology that ensures efficient power distribution, enhances vehicle performance, and contributes to the overall sustainability of electric vehicles. As EV technology continues to evolve, DC/DC converters will remain at the heart of the powertrain, helping to address challenges related to efficiency, size, and cost. With ongoing advancements in materials and control strategies, these converters will play an even more vital role in shaping the future of electric mobility.

As the electric vehicle industry continues to grow, understanding the importance of DC/DC converter for electric vehicles will be key for both manufacturers and consumers seeking to optimize their EVs for better performance, energy efficiency, and sustainability.

Read More: What Are the Benefits of Using Flat Wire Motor in EV