What is an Inverter in Electric Vehicle? What Does It Do in EV Car?

Introduction

Electric vehicles (EVs) have become a symbol of modern innovation, sustainability, and environmental responsibility. As the automotive industry shifts towards electrification, the focus on efficiency, performance, and technological advancements continues to grow. At the heart of this transformation lies a critical yet often overlooked component—the inverter in electric vehicles.

The inverter plays a vital role in the seamless operation of EVs, ensuring that the energy stored in the battery is efficiently utilized to power the motor. This blog delves deep into what an inverter is, how it functions, and its impact on the performance of EVs. We’ll also explore the key technologies behind modern inverters, the challenges they face, and the trends shaping their future.

What is an Inverter in Electric Vehicles?

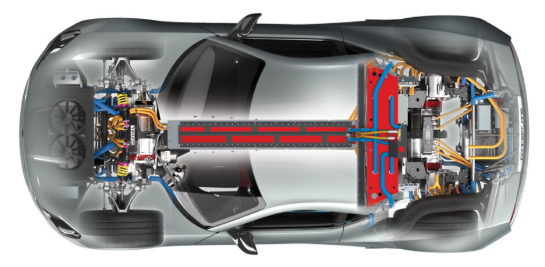

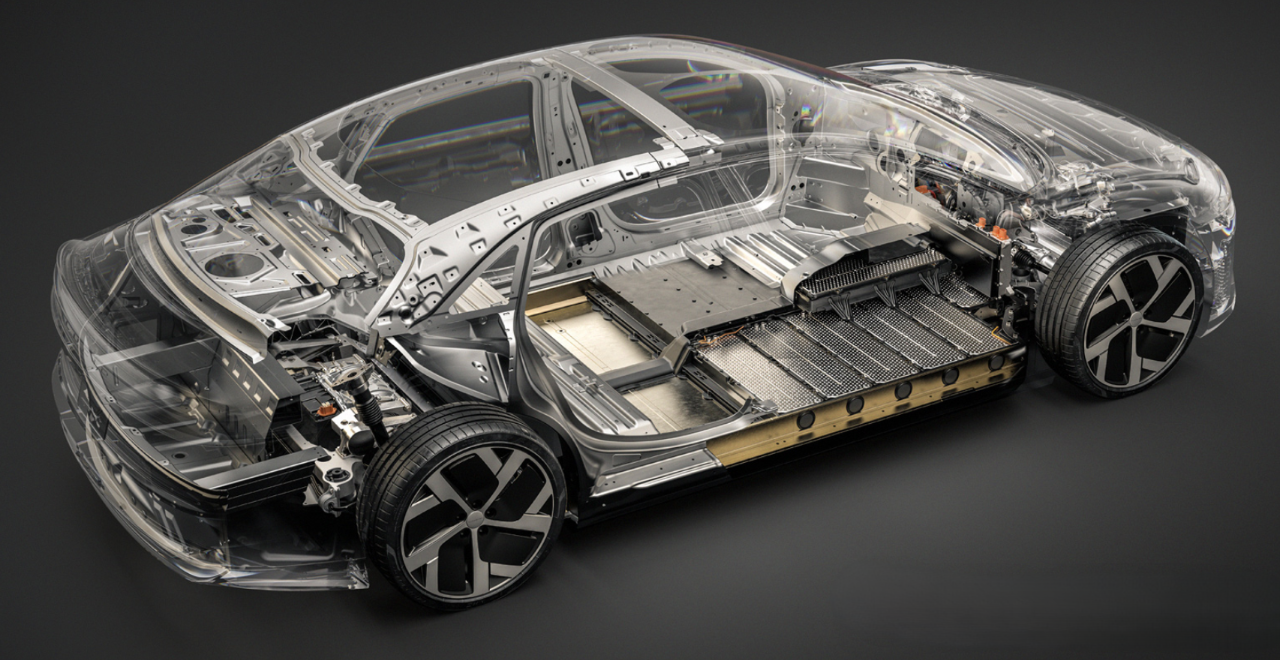

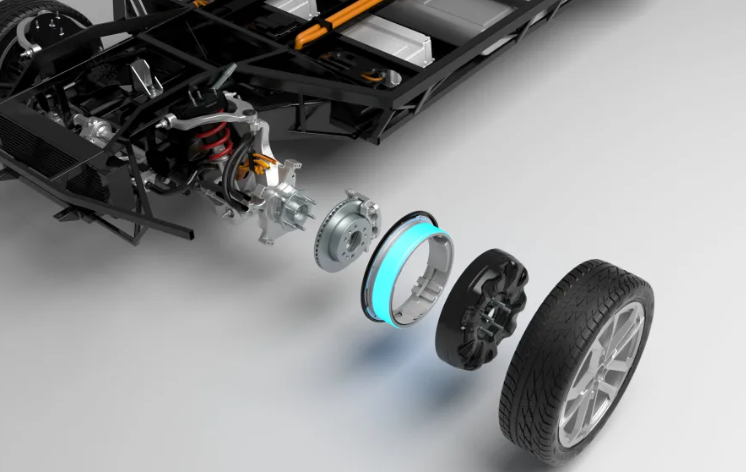

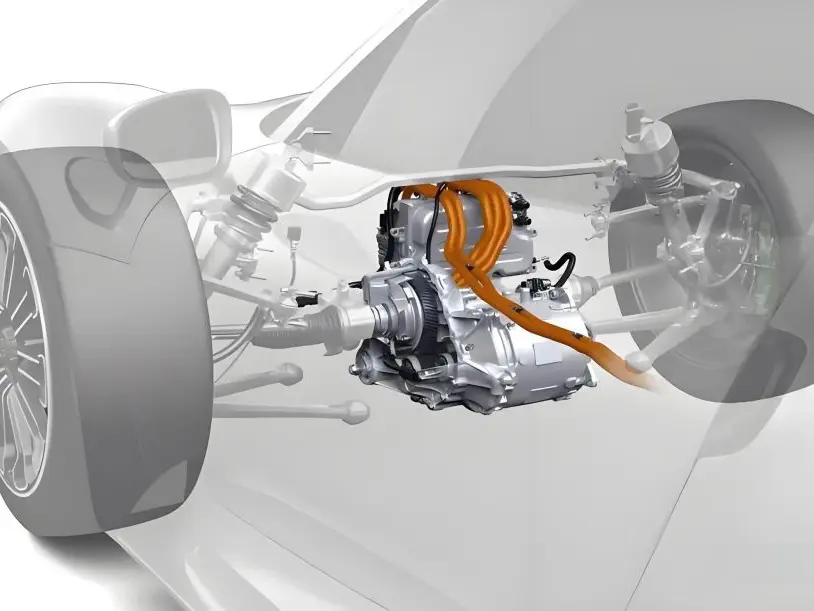

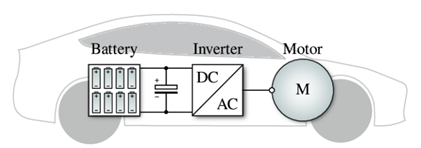

An inverter for EV cars is a crucial electrical component that ensures the seamless operation of an electric vehicle by converting direct current (DC) from the vehicle’s battery into alternating current (AC) required by the motor. Since most EVs utilize AC motors due to their superior efficiency, reliability, and ability to handle varying speeds and loads, the inverter acts as the intermediary, bridging the gap between the battery and the motor.

There are two main types of inverter architectures. The first is a box-type inverter that is individually packaged. It is commonly used by many OEMs and Tier1s. They have the advantage of easy assembly and modularity. The second is the integrated inverter design, which is part of the drivetrain. The motor, transmission and inverter are packaged in the same housing (e.g. Tesla). One of the key factors that determine the performance of an inverter is the type of semiconductor used in switching technology. Currently, four different types of semiconductor switching technologies are being used in the inverters of electric vehicles. These include silicon-based devices, MOSFETs and IGBTs, as well as switching devices based on wideband gap materials (SIC or GAN).

Electric vehicles currently mainly use silicon-based inverters, but with the increasing level of electrification, there is a shift to $IC transistor-based inverters, mainly for systems above 650V.

SIC offers higher electric field breakdown capability, better thermal conductivity, higher temperature operation capability, and higher switching frequencies due to the wider electronic bandgap, resulting in lower losses than silicon-based semiconductor devices. SIC material also minimizes switching losses.

GAN has similar properties, but its band gap (3.4 eV) is higher than that of SIC (3 eV). The inherent characteristics of GANs allow for faster switching capability, further improving the performance of the inverter. In some voltage architectures, the efficiency of GANs is even higher than that of SICs. GANs are still a relatively new technology in vehicle inverters. However, it has the advantage of using a silicon substrate and is therefore much less costly. The higher power density of these semiconductors makes the inverter smaller and lighter.

Key Components of an Inverter:

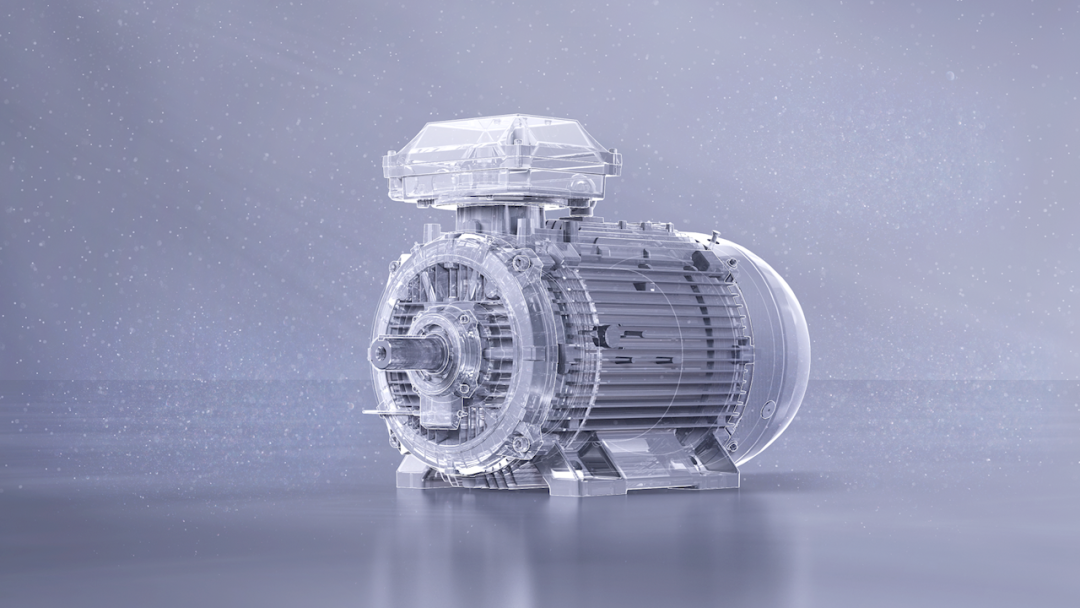

1.Power Electronic Switches

Advanced components such as insulated-gate bipolar transistors (IGBTs) or silicon carbide (SiC) transistors are used to manage the DC-to-AC conversion process. These switches operate at high speeds, enabling precise control of the electrical flow to the motor.

2.Controller

Often referred to as the brain of the inverter, the controller regulates critical parameters such as voltage, frequency, and power output. It ensures that the motor operates efficiently under various driving conditions, including acceleration and deceleration.

3.Cooling System

Power conversion generates significant heat, which can impact performance and durability. Cooling systems, such as liquid cooling or heat sinks, prevent overheating and maintain the inverter's operational efficiency.

4.Housing

The inverter is encased in a durable housing that protects internal components from environmental factors like dust, moisture, and vibrations, ensuring reliability and longevity.

Without the inverter, the DC energy stored in the battery would be incompatible with the AC motor, rendering the vehicle non-functional. This essential component not only powers the motor but also plays a vital role in energy efficiency, performance optimization, and regenerative braking, making it indispensable in the design and operation of modern electric vehicles.

The Role of Inverters in Electric Vehicles

An inverter in electric vehicles plays a multifaceted role, acting as more than just a converter. It serves as a vital intermediary between the battery and the motor, ensuring smooth and efficient functionality of the EV. Below are the critical roles performed by the inverter:

1. Power Conversion

The inverter’s fundamental task is to convert direct current (DC) power from the battery into alternating current (AC) power required by the motor. This conversion is essential for generating the rotational motion needed to propel the vehicle. Without this process, the DC energy stored in the battery would remain unusable for driving.

2. Motor Speed and Torque Control

Inverters regulate the frequency and amplitude of the AC power delivered to the motor. This control enables precise adjustments to the motor’s speed and torque, ensuring smooth acceleration, deceleration, and braking. Whether cruising on a highway or navigating stop-and-go traffic, the inverter ensures a responsive and comfortable driving experience.

3. Energy Regeneration

During regenerative braking, the motor functions as a generator, converting the vehicle’s kinetic energy back into electrical energy. The inverter then converts this regenerated energy from AC to DC and channels it back into the battery. This process improves overall energy efficiency, extending the driving range of the EV.

4. Power Distribution Management

The inverter collaborates with the vehicle’s power management system to distribute energy optimally. For instance, it ensures efficient power delivery during energy-intensive scenarios such as uphill climbs, sudden accelerations, or towing, adapting to real-time demands.

5. Battery Protection

By regulating the flow of power, the inverter protects the battery from potential overloads or unsafe operating conditions. This ensures the longevity and safety of the battery system while maintaining consistent performance.

How Inverters Impact EV Performance

The inverter for EV cars plays a pivotal role in shaping various performance aspects of an electric vehicle. Its influence extends across acceleration, energy efficiency, temperature management, driving comfort, and system compatibility. Here's how inverters significantly impact EV performance:

1. Acceleration and Speed

The inverter precisely controls the motor’s speed and torque by regulating the frequency and amplitude of the AC power it delivers. This control directly affects how quickly the vehicle accelerates and how efficiently it maintains high speeds. A well-designed inverter ensures a balance between performance and energy consumption, offering smooth and powerful acceleration.

2. Energy Efficiency

Energy efficiency is a cornerstone of EV performance, and the inverter is central to this. By minimizing energy losses during the DC-to-AC conversion process, high-efficiency inverters maximize the usable energy from the battery. This directly translates into longer driving ranges, a critical factor for the broader adoption of electric vehicles. In inverters, due to cost advantages, the current mainstream solution is based on silicon-based IGBI. With the widespread use of SiC, the main drive voltage level is also accelerating from today's 400V to 800V. Behind the technological change, it is actually to meet the needs of high efficiency, high power density, etc. Compared with silicon-based IGBTs, SiC MOSFETs have less drag current when the device is turned off, and the switching loss of the device will also be smaller. At the same time, the current required output of the inverter is much lower than the rated current value under the daily low-load condition of electric vehicles, while the conduction loss of SiC MOSFETs is much lower than that of IGBTs at medium and low currents, and has a significant efficiency improvement in the overall system.

3. Temperature Regulation

During operation, inverters generate heat, which can affect performance and reliability if not properly managed. Modern inverters incorporate advanced thermal management systems, such as liquid cooling or heat sinks, to maintain optimal operating temperatures. This ensures consistent performance and prevents thermal degradation of components.

4. Driving Comfort

The inverter enhances the driving experience by delivering smooth and responsive power management. Whether during sudden accelerations, regenerative braking, or steady cruising, the inverter ensures seamless transitions, contributing to a comfortable and enjoyable ride.

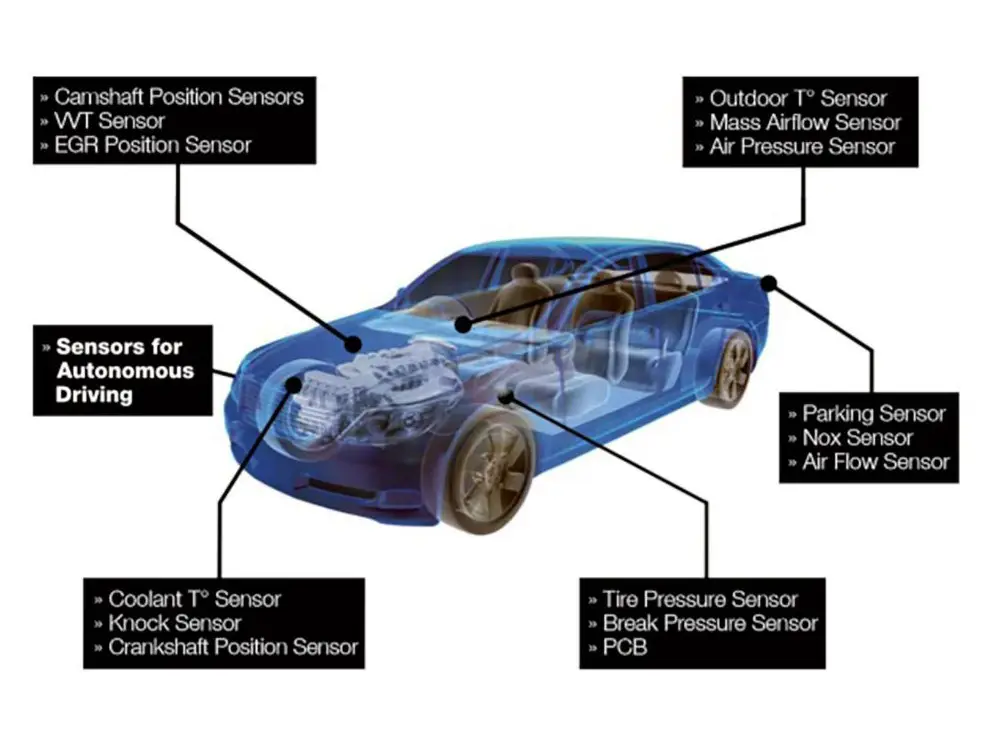

5. Compatibility with Other Systems

Inverters are integral to the EV’s broader ecosystem. They work in harmony with vehicle control units (VCUs), charging systems, and regenerative braking systems, ensuring cohesive and efficient operation. This integration enhances overall vehicle performance and reliability.

In essence, the inverter is a cornerstone of EV performance, influencing efficiency, responsiveness, and system harmony to deliver an optimized driving experience.

6. Power density

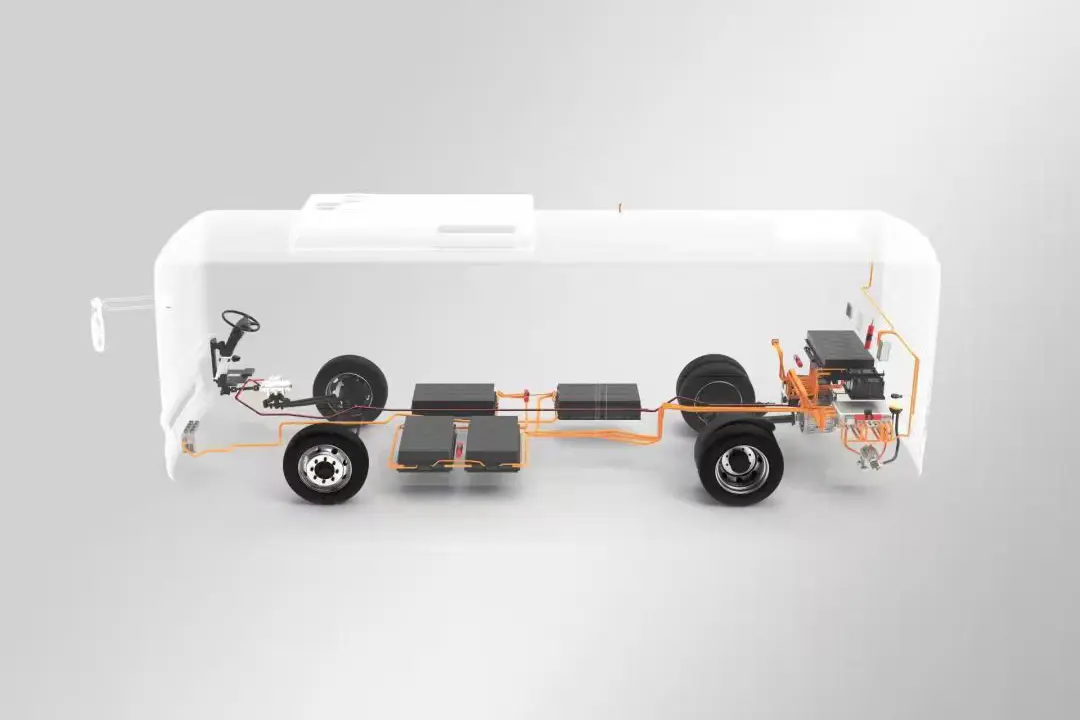

SiC MOSFETs can operate at higher switching frequencies and lower losses, so they have lower heat dissipation requirements, which can effectively reduce the weight and volume of drive components and water-cooled components: at the same time, the high switching frequency also reduces the size and cost of passive components, so the volume of the SiC main drive inverter can be greatly reduced at the same power. However, under the 800V platform, due to the doubling of the voltage, in addition to IGBTs, SIG MOSFETs and other inverters, the withstand voltage value needs to be generally upgraded to 1200V, and there are also a variety of devices, including MCUs, gate drivers, current sensors, etc., that require higher performance. For example, due to cost considerations, SIC is used in the main drive inverter and silicon IGBT is used in the auxiliary drive inverter. The motor layout has front and rear dual motors, rear two front one, rear single motor, front single motor, etc.; The current drive solutions of HEVs and PHEVs are even more diverse, such as engine series, parallel, hybrid, range extension, etc., and a variety of drive schemes are extended according to the distribution of motors and whether the engine has a direct drive part.

Key Technologies in Modern EV Inverters

Technological advancements have significantly improved the design and performance of inverters in electric vehicles. Below are some key innovations:

1.Silicon Carbide (SiC) Semiconductors

SiC technology enables inverters to operate at higher voltages and temperatures, resulting in improved efficiency, reduced energy losses, and smaller component sizes.

2.Wide Bandgap Materials

Materials like gallium nitride (GaN) and silicon carbide (SiC) are gaining traction due to their ability to handle higher frequencies and voltages with minimal losses.

3.Advanced Control Algorithms

These algorithms optimize the inverter’s performance by fine-tuning motor control and energy conversion in real time.

4.Integrated Thermal Management

Modern inverters incorporate innovative cooling solutions, such as heat sinks and liquid cooling systems, to maintain optimal performance under varying conditions.

5.Modular and Scalable Designs

Modular inverters allow manufacturers to adapt them for different EV models, reducing development time and costs.

6.Wireless Communication and Diagnostics

Advanced inverters can communicate with onboard systems, providing real-time performance data and enabling predictive maintenance.

Challenges and Limitations of EV Inverters

While inverters are indispensable to EVs, they are not without challenges:

1.Cost Constraints

High-performance inverters, particularly those using SiC technology, are expensive, impacting the overall cost of EVs.

2.Heat Management

The conversion process generates significant heat, requiring efficient and reliable cooling systems.

3.Size and Weight

Compact and lightweight inverters are essential for optimizing vehicle design and energy efficiency.

4.Durability

Inverters must endure harsh conditions, including extreme temperatures, vibrations, and prolonged use.

5.Complex Maintenance

While inverters are generally reliable, diagnosing and repairing issues can be complex, requiring specialized knowledge and tools.

Future Trends in EV Inverter Technology

Looking at the development of inverters in recent years, the trends are as follows

1. Higher efficiency: Under the demand for the range of new electric vehicles, higher efficiency inverters have become the mainstream demand.

2. Higher power density: In the era of electric vehicles, the power of the motor is getting larger and larger, and at the same time, the peak power to be supported by the inverter is also larger, and the inverter with higher power density is required in the limited space of the vehicle.

3. Low cost: In the process of continuous expansion of the electric vehicle market, it is necessary to continue to reduce the cost of the whole vehicle, and the inverter, as one of the core components of the vehicle, the market will inevitably have a greater demand for its cost reduction and efficiency increase.

4. Safe and reliable: In the case of the rapid overall technology iteration, how to ensure the stability and reliability of the overall work of the inverter is also one of the most concerned points of users.

5. Sustainable materials and manufacturing processes will also be a focus to reduce the environmental impact of inverter production.

It's worth mentioning that, from a technical level, moving the higher energy density will make the inverter smaller and lighter without compromising performance. However, to achieve these goals, it is not simple, and to improve the conversion efficiency of the inverter, it is necessary to optimize many aspects from the device, chip, drive circuit design to heat dissipation design. For example, the use of lower loss power devices, gate driver I, or enhanced heat dissipation performance of power modules. The integration of future inverters with power electronics can combine functions such as on-board charging and DC/DC conversion into a single compact unit. Therefore, for electric vehicles, PUMBAA's inverter solutions can bring longer cruising range to electric vehicles in terms of high energy efficiency; The high power density results in a smaller traction system, which can expand the interior space. Flexible solution adaptation can help reduce costs for electric vehicles; In terms of safety and reliability, PUMBAA is proud of its product advantages, as evidenced by the excellent feedback on the application of many electric vehicle products.

Conclusion

The inverter in electric vehicles is a cornerstone of EV technology, enabling efficient power conversion, motor control, and energy regeneration. As EV adoption continues to grow, advancements in inverter technology will play a critical role in enhancing vehicle performance, efficiency, and sustainability.

By understanding the significance of the inverter for EV cars, we gain insight into the technological marvels driving the electric revolution. With ongoing innovations and a commitment to overcoming current challenges, inverters will remain a key enabler of the future of transportation.

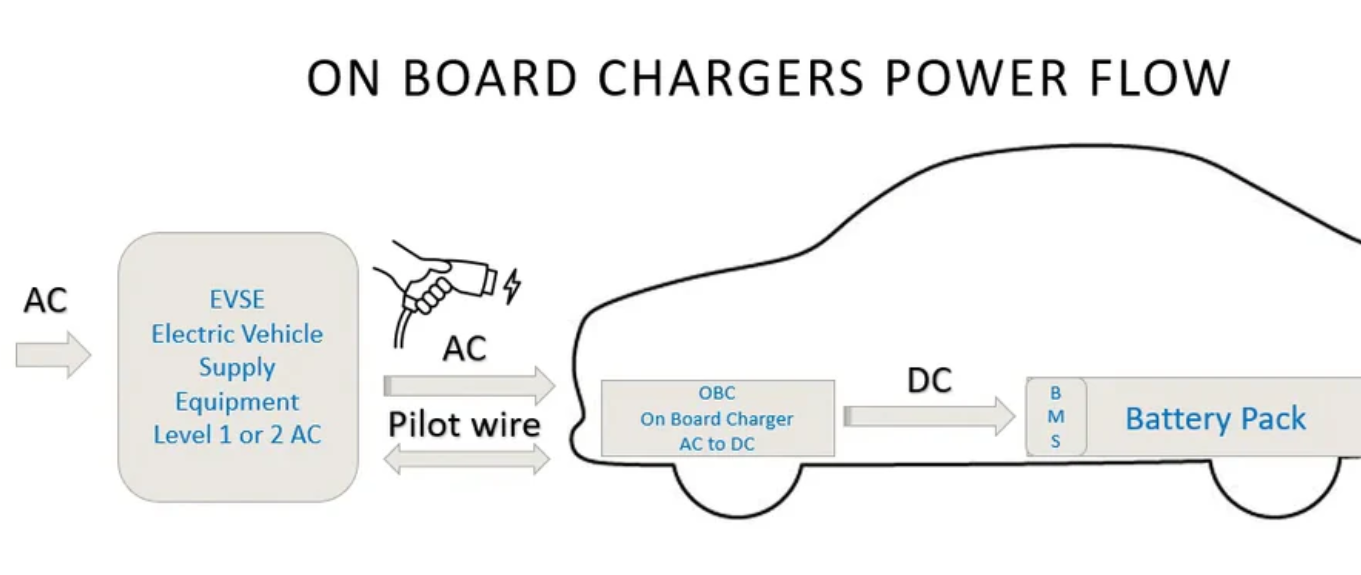

Read More: What is an OBC (On Board Charger)? A Comprehensive Guide to Electric Vehicle Charging