What Are the Benefits of Using Flat Wire Motor in EV

Electric vehicles (EVs) are revolutionizing the automotive industry, driven by advancements in technology and the increasing demand for sustainable mobility solutions. Among the many innovations shaping the EV landscape, the flat wire motor stands out as a game-changer. This blog explores the benefits of using flat wire motors in EVs, delving into their design, advantages, integration, cost-effectiveness, environmental impact, and future trends.

Introduction to Flat Wire Motors in Electric Vehicles

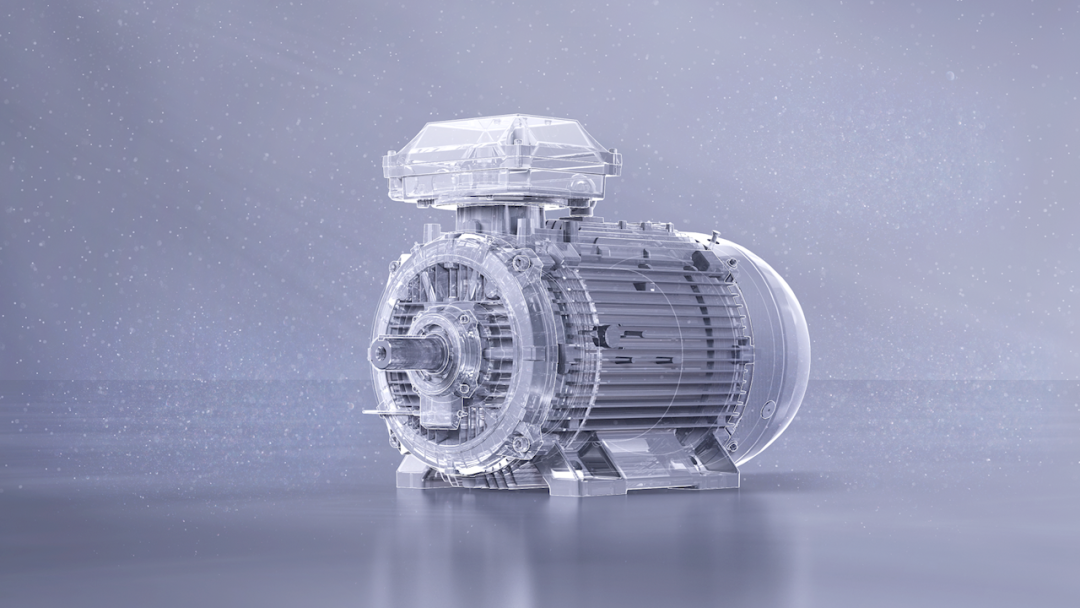

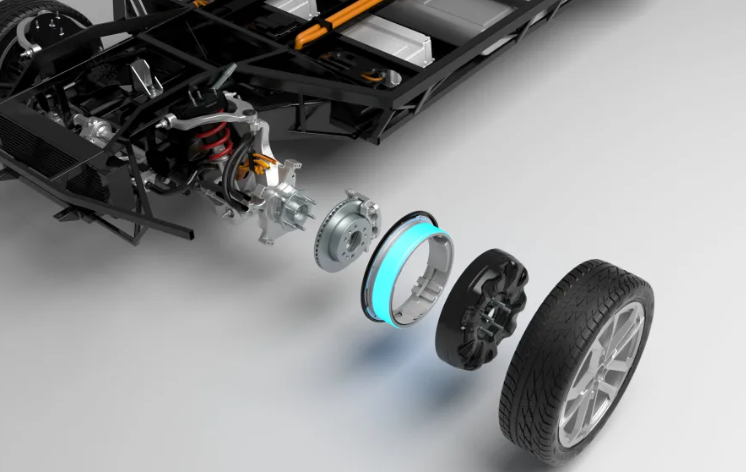

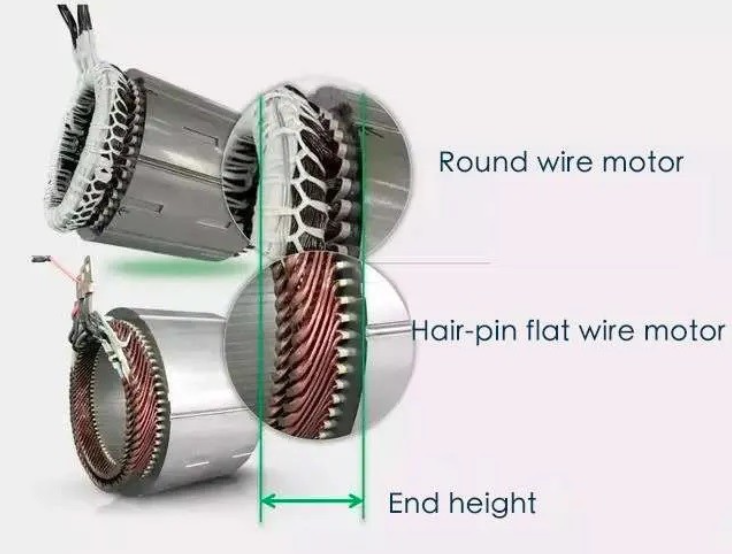

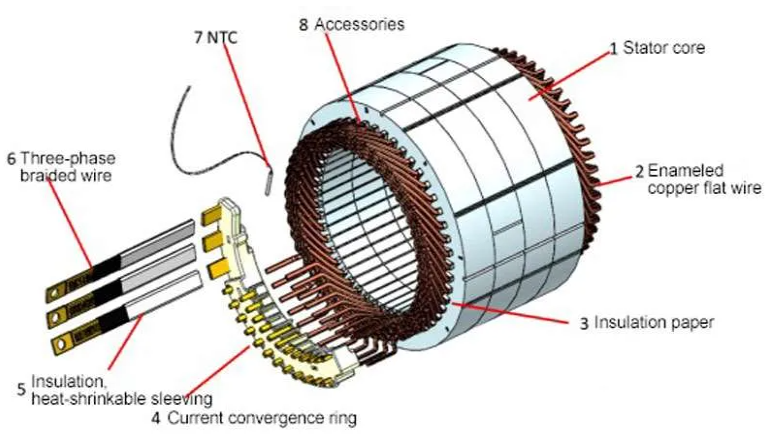

Flat wire motors represent a significant evolution in motor design, offering a more efficient and compact alternative to traditional round wire motors. These motors use flat, rectangular conductors instead of conventional round wires in their stator windings, leading to improved performance and thermal efficiency.

In the context of electric vehicles, flat wire motors address key challenges, including the need for higher energy efficiency, improved thermal management, and compactness. As EV manufacturers strive for greater energy efficiency and higher power density, flat wire motors have become a preferred choice. Their unique structure allows for better heat dissipation, reduced energy loss, and more robust mechanical properties, making them an essential component of modern electric vehicles.

Flat wire motors are becoming increasingly relevant in the race to achieve electrification goals. They provide manufacturers with the ability to design EVs that are not only high-performing but also environmentally friendly. This shift aligns with global efforts to reduce reliance on fossil fuels and minimize greenhouse gas emissions.

How Flat Wire Motors Work in Electric Vehicles

At their core, flat wire motors function similarly to traditional electric motors by converting electrical energy into mechanical motion. However, their distinctive flat wire design optimizes several key aspects, setting them apart from their round wire counterparts:

- Tighter Winding: The flat shape allows for more compact and densely packed windings, which increases the strength of the magnetic field generated by the motor. This directly enhances the motor’s performance and efficiency.

- Improved Thermal Management: The flat wires create a larger surface area for heat dissipation, which is critical in preventing overheating during high-load operations or prolonged use. Better thermal performance ensures consistent efficiency and reliability.

- Reduced Resistance: The optimized geometry of flat wires minimizes electrical resistance, which translates to reduced energy loss during operation. This efficiency contributes to longer battery life and extended driving ranges for EVs.

In electric vehicles, these features result in smoother acceleration, better torque delivery, and enhanced overall driving performance. Additionally, flat wire motors can handle the high power and voltage demands typical in modern EVs, making them well-suited for both passenger and commercial applications.

Key Advantages of Flat Wire Motors in Electric Vehicles

The adoption of flat wire motors in electric vehicles offers numerous advantages that contribute to their growing popularity. Below are some of the most significant benefits:

a) Enhanced Power Density

Flat wire motors provide a higher power-to-weight ratio than traditional motors, making them ideal for EVs where weight and space are critical considerations. The compact design allows manufacturers to use smaller motors without sacrificing performance, enabling more streamlined vehicle designs.

b) Increased Efficiency

The unique winding structure of flat wire motors reduces energy losses due to resistance and improves the utilization of the magnetic field. This higher efficiency directly impacts the EV’s range, allowing it to travel farther on a single charge. This is a crucial advantage in addressing range anxiety among EV users.

c) Superior Durability

Flat wire motors are more robust and resistant to mechanical stresses. Their construction reduces wear and tear, which ensures a longer operational lifespan compared to conventional motors. This durability is particularly important for EVs, as it minimizes maintenance costs and improves overall reliability.

d) Better Heat Dissipation

Thermal management is a critical factor in electric vehicle performance. Flat wire motors excel in dissipating heat efficiently, which prevents performance degradation during prolonged use or in extreme environmental conditions. This feature also contributes to the longevity of the motor.

e) Noise Reduction

The compact windings and precise construction of flat wire motors reduce vibrations and operational noise. This results in a quieter and more comfortable driving experience, aligning with the overall appeal of EVs as smooth and silent vehicles.

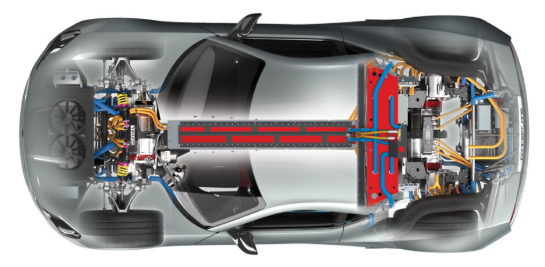

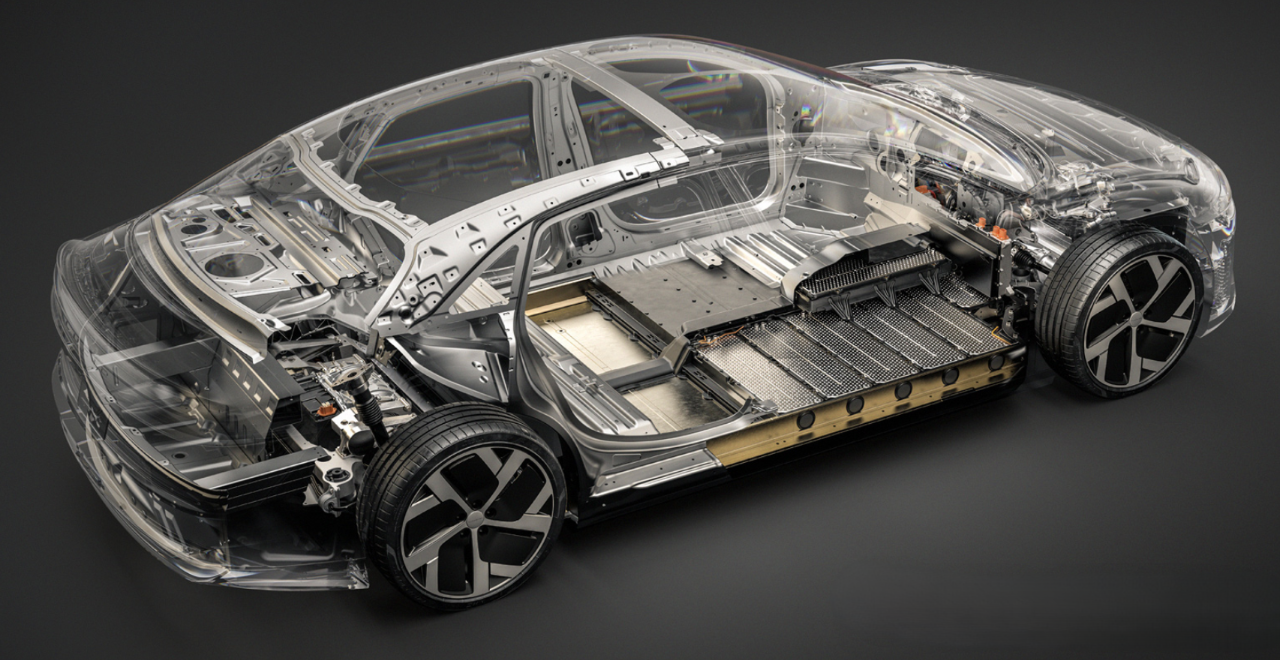

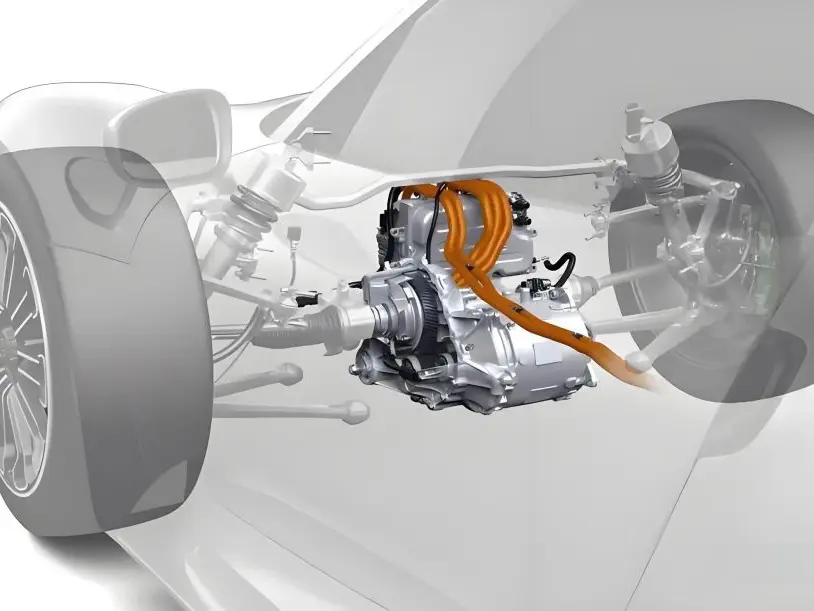

Integration of Flat Wire Motors in Electric Vehicle Powertrains

Integrating flat wire motors into EV powertrains involves a seamless blend of innovation and engineering. These motors are designed to complement advanced power electronics, battery systems, and drivetrain components, maximizing their potential.

Key considerations for integration include:

- Compact Design: The reduced size of flat wire motors allows for better packaging within the EV chassis. This is particularly beneficial in smaller vehicles where space constraints are significant.

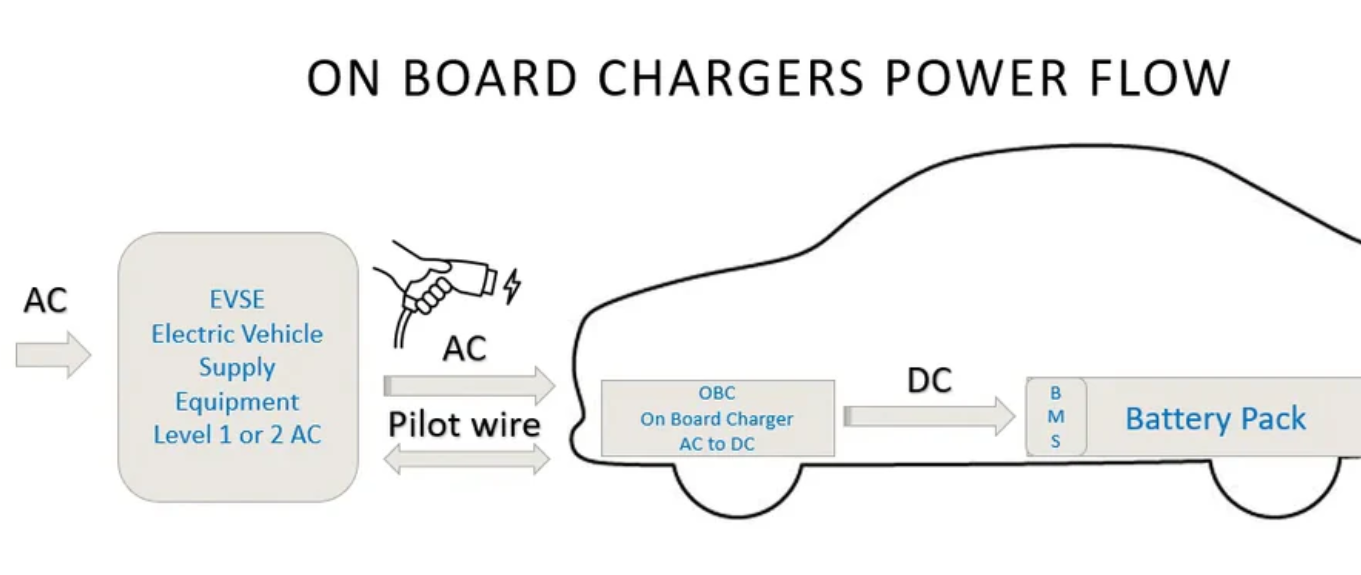

- Compatibility with High-Voltage Systems: Flat wire motors are capable of efficiently handling the high voltages typical in modern EVs. This compatibility enhances their performance and ensures reliability under demanding conditions.

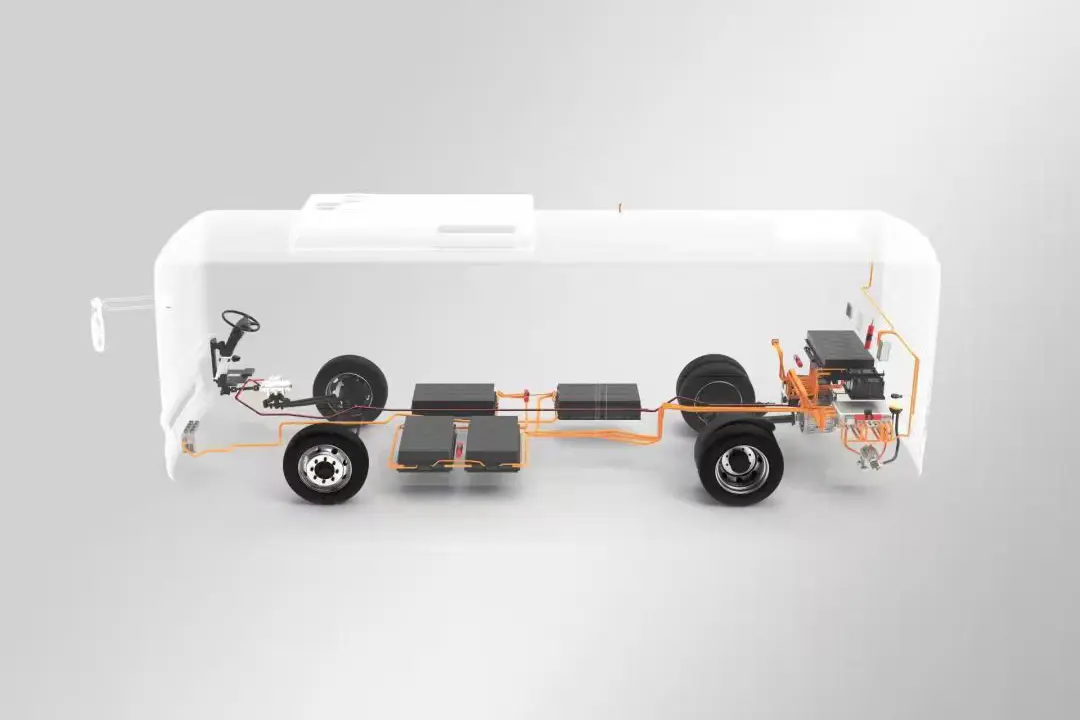

- Scalability: These motors are adaptable to various vehicle types, from compact city cars to larger trucks and buses. This versatility makes them a valuable choice for manufacturers aiming to diversify their EV offerings.

The integration of flat wire motors also involves leveraging their thermal efficiency and durability to reduce wear on other powertrain components. This holistic approach to design results in EVs that are more efficient, reliable, and cost-effective to operate.

Cost-Effectiveness and Manufacturing Benefits

Despite their advanced design, flat wire motors offer several cost and manufacturing advantages, making them an attractive choice for EV manufacturers:

a) Material Efficiency

The use of flat wires allows for tighter winding and reduced material waste. This efficiency not only lowers production costs but also aligns with sustainability goals by minimizing resource consumption.

b) Simplified Manufacturing

Flat wire motors often involve fewer production steps compared to traditional motors. This streamlined manufacturing process reduces labor costs and accelerates production timelines, enabling manufacturers to scale up production to meet market demands.

c) Scalability

The design of flat wire motors supports mass production without compromising quality. This scalability is essential as the demand for electric vehicles continues to grow globally. Manufacturers can produce flat wire motors at competitive costs, making EVs more accessible to a wider audience.

While the initial investment in developing flat wire motor technology may be higher, the long-term cost savings and performance benefits make them a worthwhile choice for EV manufacturers. Additionally, their durability and efficiency reduce the total cost of ownership for consumers.

Environmental Impact of Flat Wire Motors

Sustainability is a cornerstone of the EV movement, and flat wire motors contribute significantly to this goal in the following ways:

a) Energy Efficiency

Flat wire motors’ higher efficiency means less energy consumption per mile, reducing the overall environmental footprint of electric vehicles. This efficiency also translates to fewer greenhouse gas emissions during electricity generation.

b) Reduced Resource Use

The compact design and efficient use of materials in flat wire motors minimize resource consumption during manufacturing. This reduction aligns with the automotive industry’s efforts to create more sustainable supply chains.

c) Longevity

Flat wire motors’ durable design ensures a longer operational lifespan, reducing the frequency of replacements and the associated environmental impact of production and disposal.

d) Recyclability

Many components of flat wire motors, such as the copper wires and steel laminations, are recyclable. This feature supports the creation of a circular economy in the automotive industry, further reducing waste and promoting sustainability.

By enabling more efficient and sustainable electric vehicles, flat wire motors play a crucial role in reducing greenhouse gas emissions and promoting eco-friendly transportation.

Future Trends and Developments for Flat Wire Motors in EVs

The evolution of flat wire motors is far from over. Emerging trends and technological advancements promise to unlock even greater potential for these motors in the EV sector:

a) Advanced Materials

Research into lightweight and high-strength materials could further enhance the performance and durability of flat wire motors. These advancements may lead to even more compact and efficient designs.

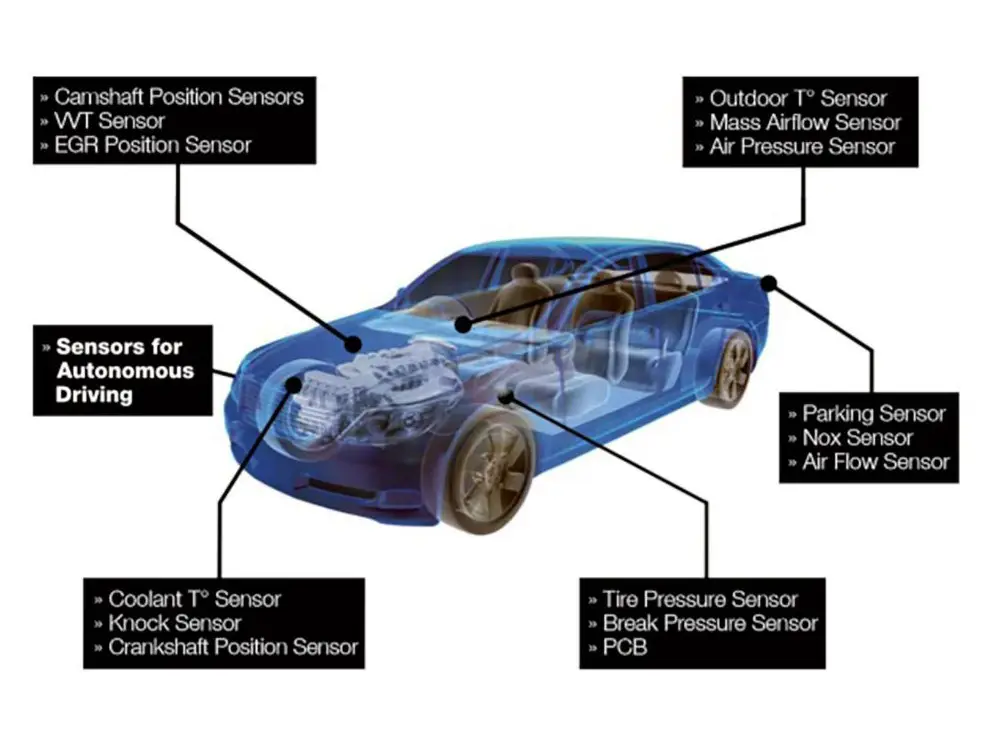

b) Integration with AI and IoT

Smart motors capable of self-monitoring and optimization using artificial intelligence (AI) and the Internet of Things (IoT) are on the horizon. These innovations could improve efficiency, reliability, and predictive maintenance.

c) Modular Designs

Future flat wire motors may feature modular designs, enabling easier upgrades and repairs. This modularity reduces downtime and extends the lifecycle of both the motor and the vehicle.

d) Application in Autonomous Vehicles

The efficiency and compactness of flat wire motors make them ideal for the next generation of autonomous EVs, where space and energy efficiency are paramount. These motors will likely play a key role in powering self-driving technologies.

e) Wider Adoption in Commercial Vehicles

As flat wire motor technology advances, its adoption in commercial EVs, such as delivery trucks and public transportation, is expected to grow. These applications will benefit from the motors’ durability, efficiency, and scalability.

Conclusion

The flat wire motor is a transformative technology for the electric vehicle industry. Its superior efficiency, compact design, durability, and environmental benefits make it a cornerstone of modern EV powertrains. As the demand for sustainable mobility grows, flat wire motors are poised to play an even more significant role, driving innovation and shaping the future of electric vehicles.

From enhanced performance to reduced environmental impact, flat wire motors exemplify the progress and promise of the EV revolution. Whether you’re an EV enthusiast or a manufacturer, understanding the benefits of this cutting-edge technology is essential to appreciating the advancements shaping the automotive landscape.

Read More: The Ultimate Guide to Electric Drive Axle