What is an OBC (On Board Charger)? A Comprehensive Guide to Electric Vehicle Charging

Electric vehicles (EVs) are revolutionizing the way we think about transportation, offering an eco-friendly and efficient alternative to traditional vehicles. However, one critical aspect of EV ownership is understanding how these vehicles charge and the technology that makes it possible. At the core of this system is the OBC (On Board Charger), a key component responsible for converting electricity into usable energy for the battery.

Introduction

The global shift toward electric mobility is driven by a need to reduce greenhouse gas emissions, minimize reliance on fossil fuels, and embrace renewable energy sources. As EVs become more common, so does the need to understand their charging systems.

Charging an EV involves much more than plugging it into an outlet. It requires a sophisticated mechanism to convert the power from the grid into a form the vehicle’s battery can use. The OBC (On Board Charger) is this mechanism.

This guide provides insights into the EV OBC’s functionality, why it’s integral to EVs, and how it compares to external chargers, equipping you with the knowledge to make informed decisions about your EV’s charging needs.

What is an OBC (On Board Charger)?

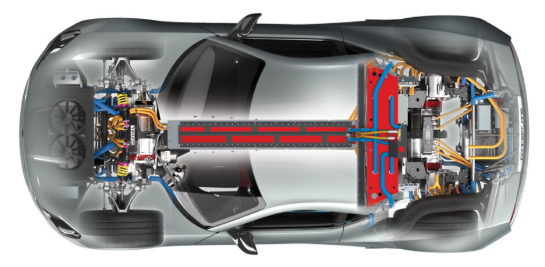

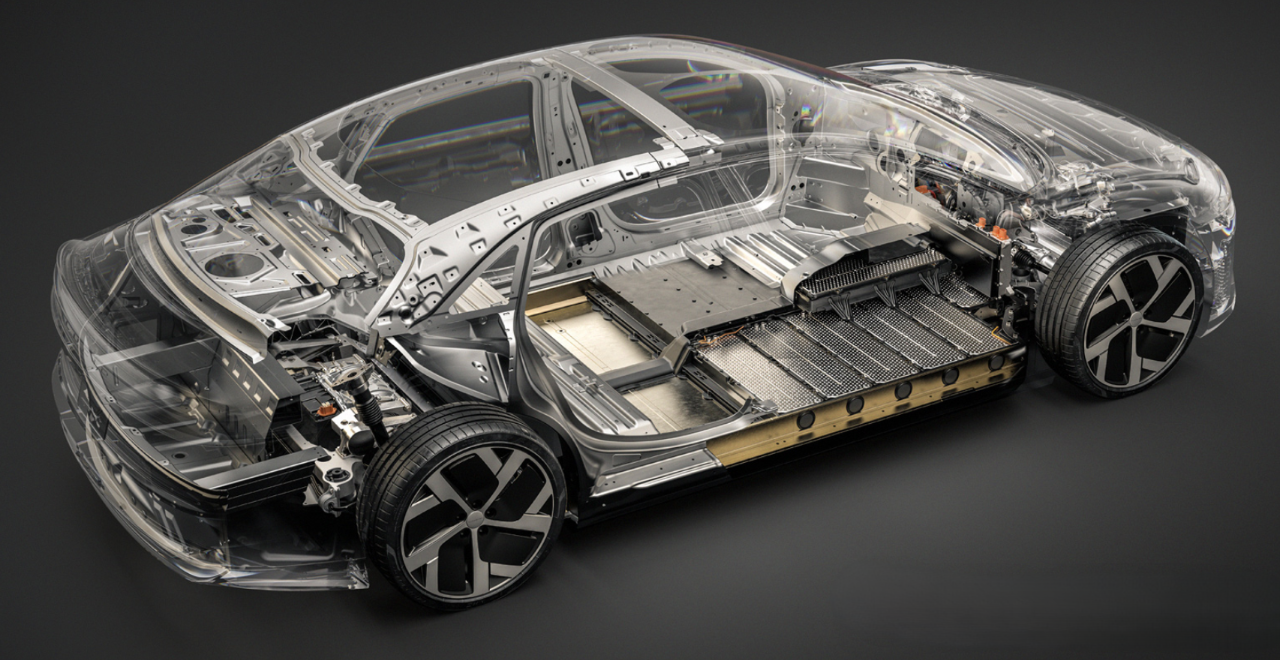

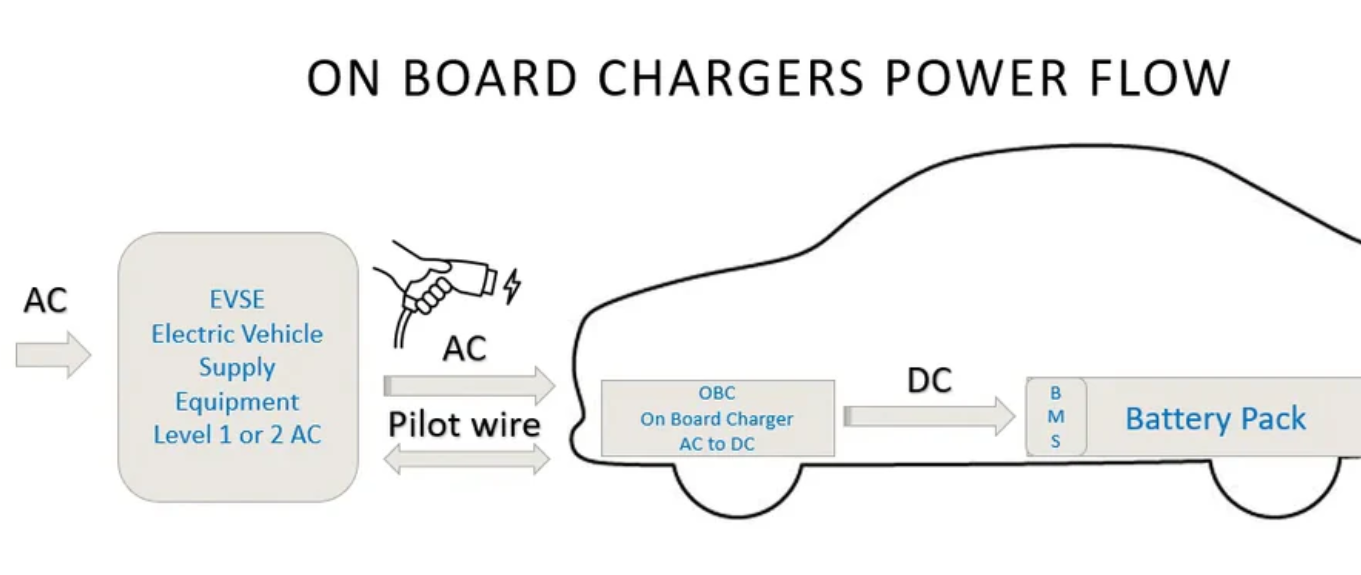

An OBC (On Board Charger) is a crucial component integrated into electric vehicles (EVs) that facilitates the charging process. The EV OBC’s primary function is to convert alternating current (AC) from an external power source—such as a standard home outlet or a public charging station—into direct current (DC), which is then stored in the vehicle’s battery. This conversion is necessary because electric vehicle batteries can only store and use DC power, while most power sources, like electrical outlets, supply AC power.

Key Functions of an EV OBC:

1.Power Conversion:

The EV OBC efficiently converts the incoming AC electricity from the grid into DC power that can be used by the vehicle’s battery. This process ensures that the vehicle’s battery receives the right type of power for storage. The efficiency of this conversion is crucial for maximizing energy usage and minimizing waste during the charging process.

2.Charging Management:

The EV OBC doesn’t just convert power; it also manages the charging process itself. It regulates the amount of current and voltage supplied to the battery, ensuring that the battery charges safely and efficiently. This regulation helps avoid damage from improper charging, ensuring the battery operates at peak performance.

3.Battery Protection:

The EV OBC is also responsible for protecting the battery during the charging process. It monitors factors such as temperature and voltage to prevent overcharging or overheating, which could reduce the battery’s lifespan. This feature ensures that the battery is charged in a controlled environment, extending its longevity and maintaining optimal performance.

Without an EV OBC, EVs would require bulky external chargers to perform these functions, making the charging process far less convenient and less integrated into the vehicle’s design. The OBC allows for seamless, in-vehicle charging that is essential for the convenience and functionality of electric vehicles.

How Does an OBC Work?

An On Board Charger (OBC) is a vital component of an electric vehicle (EV), functioning as an intermediary between the external power source and the vehicle's battery. The OBC ensures that the vehicle receives the proper type and amount of power needed to charge its battery safely and efficiently. Here’s a detailed look at how the OBC works:

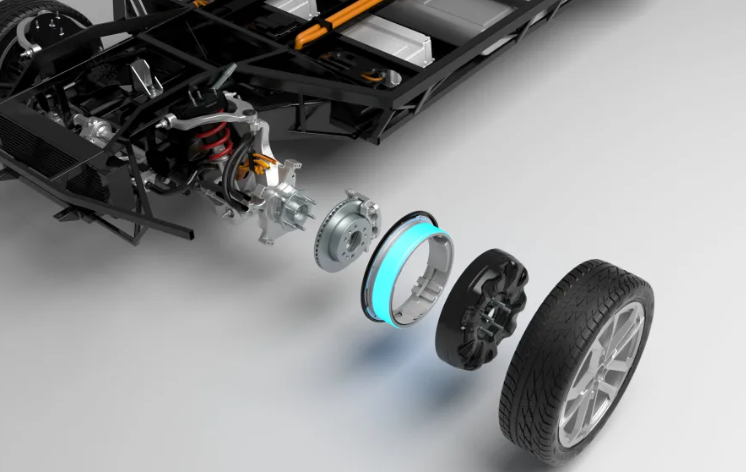

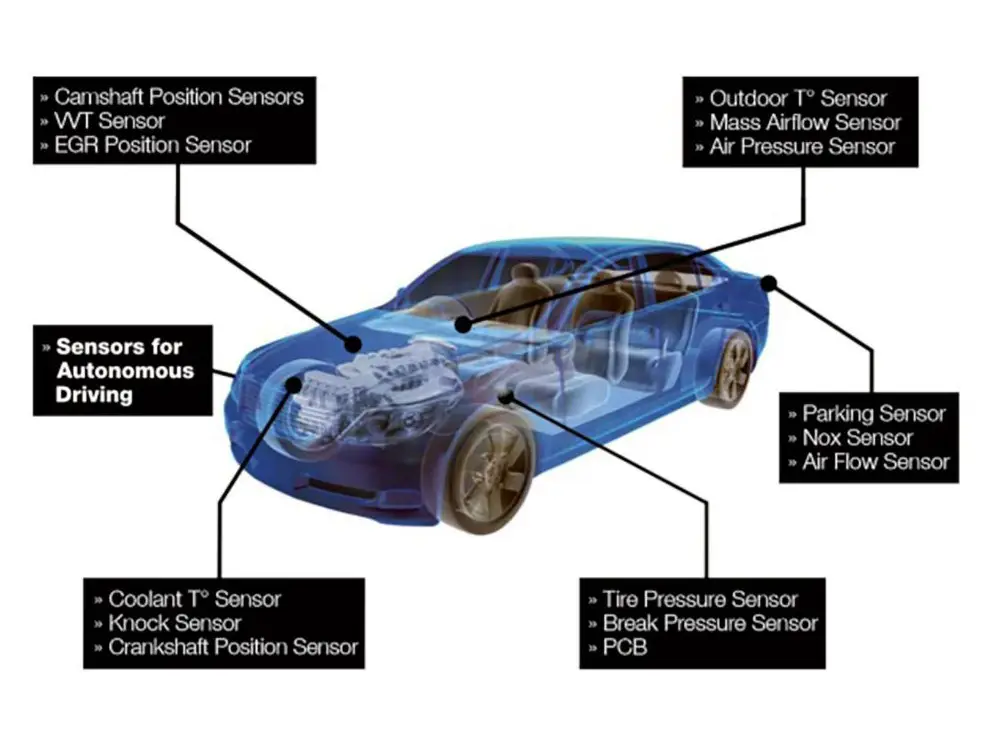

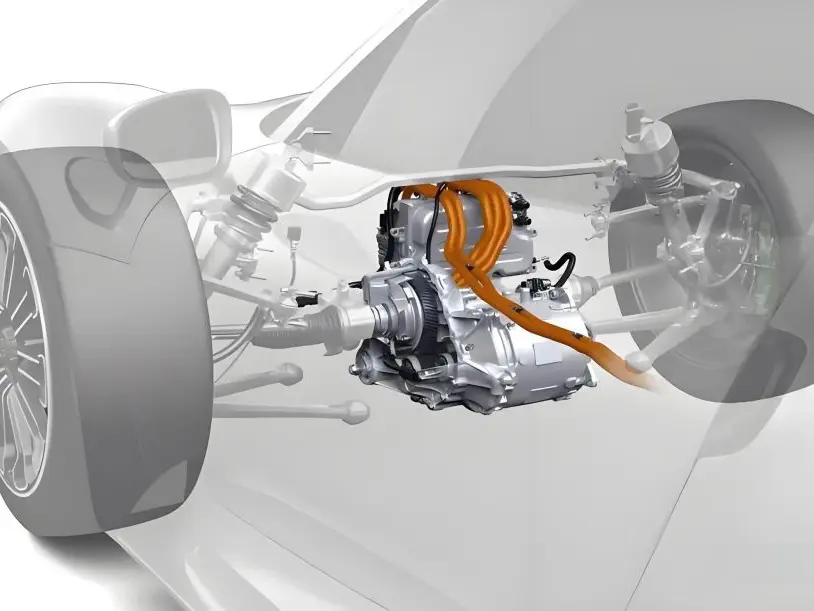

On-board chargers play an important role in electric vehicles, with a variety of functions, and it is important to communicate with the BMS (battery management system) and vehicle monitoring systems. Through the high-speed network CAN to interact with the BMS, it can dynamically output the current and voltage parameters that are most suitable for the state of the power battery according to the instructions of the BMS, and select the optimal charging mode for the battery pack. During the charging process, the BMS mainly monitors the voltage, current, temperature and connection status of the power battery pack to control and protect the battery. Communicate with the vehicle monitoring system through the high-speed CAN network, upload its own working status, working parameters and fault alarm information, and accept the control command to start charging or stop charging. In addition, it also has complete security protection functions. For example, AC input over-voltage protection, AC input under-voltage alarm, AC input over-current protection, DC output over-current protection, DC output short-circuit protection, output soft start, current shock prevention, flame retardant, etc. These functions protect the battery during charging, prevent the occurrence of dangerous situations such as overheating, overcharging and short circuit, and ensure the safe and stable operation of the battery. The on-board OBC consists of multiple parts, including an AC input port, a power unit, a control unit, a low-voltage auxiliary unit, and a DC output port. The AC input port is responsible for receiving AC power from the power grid, and generally has 7 PIN ports and three types of connections. The standard input interface adopts a power frequency single-phase input voltage of 220V, and if the power is required, two spare pins can also be enabled to achieve 380V input.

As the transmission channel of charging energy, the power unit mainly includes electromagnetic interference suppression module, rectifier module, power factor correction module, filter module, full-bridge conversion module and DC output module. With the cooperation of the control unit, the input power frequency alternating current is converted into direct current suitable for the appropriate voltage that the power battery system can accept. The control unit is the core part of the on-board charger, which controls the conversion process of the power unit through the switching device, accurately completes the conversion function through closed-loop control, and provides protection functions. It mainly includes primary side detection and protection module, over-current detection and protection module, over-voltage/under-voltage monitoring and protection module and DSP main control module. The low-voltage auxiliary unit provides low-voltage power supply to the electronics of the control unit and realizes the connection between the system and the outside world. It mainly includes CAN communication module, auxiliary power supply module and human-computer interaction module. The DC output port is responsible for providing DC power to the battery, including two pins on the positive and negative poles of the low-voltage auxiliary power supply, two pins on the positive and negative poles of the high-voltage charging circuit, the ground, the communication lines CANH and CANL (can also have CAN shielding), and the charging request signal line.

Types of On Board Chargers

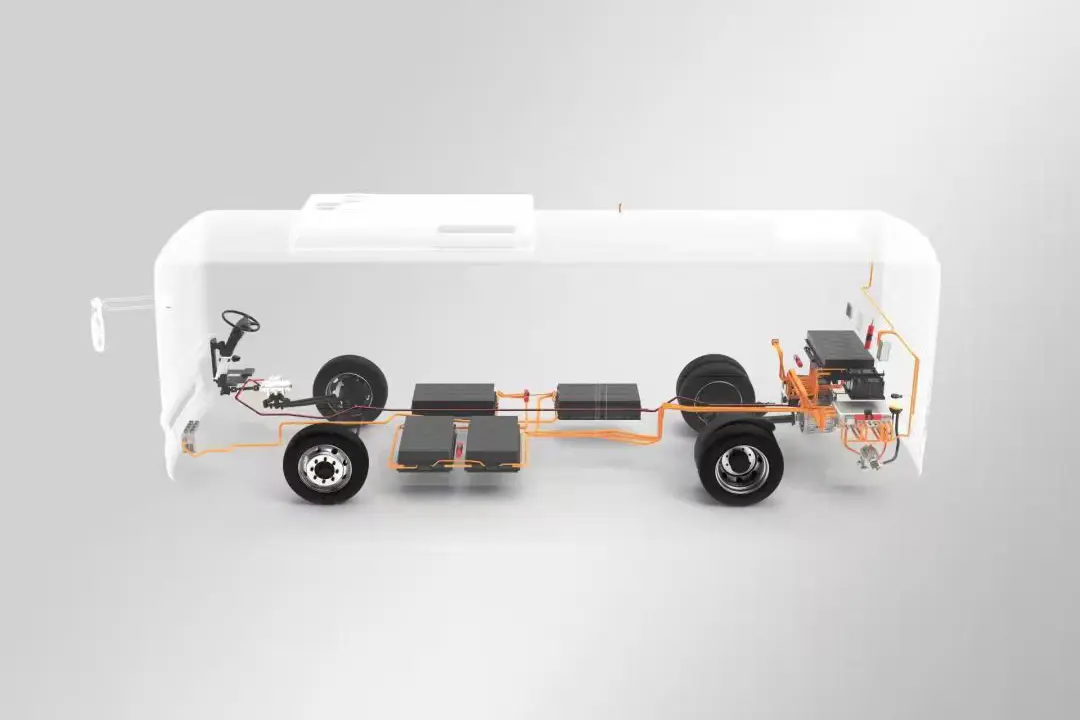

Not all OBCs are created equal. Different EV models are equipped with specific types of OBCs based on their intended usage and charging infrastructure.

In general, on-board chargers can be divided into one-way on-board chargers, two-way on-board chargers, and integrated on-board chargers.

· (Uni-Direction On-Board Charger):The power flows in one direction, generally using high-frequency switching power supply technology, and the topology is divided into single-stage structure and two-stage structure; Only the charging function.

· (Bi-Direction On-Board Charger):The power flows in both directions, mostly using a two-stage conversion structure, which is composed of a bidirectional AC-DC converter and a bidirectional DC-DC converter. There is both a charging function and an inverter function.

· The power flows in both directions, mostly using a two-stage conversion structure, which is composed of a bidirectional AC-DC converter and a bidirectional DC-DC converter. There is both a charging function and an inverter function.

· V2L(Vehicle to Load)Inverter function: take power from the on-board power battery, and provide 220VAC AC power to the ground electrical equipment through the bidirectional on-board charger, AC charging port, and special V2L AC socket board;

· V2G(Vehicle-to-grid)Inverter function: take power from the on-board power battery, and connect to the power grid through the bidirectional on-board charger, AC charging port, and ground AC charging pile.

· Integrated on-board charger: OBC、DC-DC、PDUand other on-board power integration:OBC+DC-DC2-in-1 integration、OBC+DC-DC+PDU3-in-1 integration;

· Motor, electronic control, reducer、OBC、DC-DC、BMS Equal electric drive + on-board power integration: all-in-one integration.

Advantages of Using an OBC in Electric Vehicles

The integration of an OBC (On Board Charger) into electric vehicles (EVs) offers numerous advantages that enhance the overall EV ownership experience. Here are some key benefits of using an OBC:

1. Convenience:

An OBC allows EV owners to charge their vehicles from standard power outlets or dedicated EV chargers without the need for additional external equipment. This built-in solution eliminates the hassle of carrying extra charging devices or finding specialized charging stations, making it easy to charge the vehicle at home or while on the go.

2. Efficiency:

The OBC minimizes energy loss during the conversion process from alternating current (AC) to direct current (DC). By ensuring an efficient transfer of energy, it optimizes the use of electricity, allowing for faster and more effective charging, which can save both time and money.

3. Safety:

Modern OBCs are equipped with advanced safety features, such as protection against overcharging, overheating, and short circuits. These built-in safeguards ensure the safety of the battery and the vehicle’s electrical systems, reducing the risk of damage during the charging process.

4. Portability:

As a built-in system, the OBC eliminates the need to carry bulky external charging devices. This streamlined setup makes the EV more user-friendly, with fewer components to worry about.

5. Flexibility:

OBCs are compatible with various charging standards, allowing EVs to charge at different locations, whether at home, public charging stations, or workplace chargers. This flexibility enhances the convenience of owning an EV.

6. Cost Savings:

By reducing reliance on expensive external chargers, particularly for home charging setups, an OBC helps EV owners save on upfront and long-term costs. It simplifies the charging process and eliminates the need for specialized charging equipment.

Key Features of Modern OBCs

Modern EV OBCs are designed to meet the evolving needs of electric vehicle users. Some standout features include:

- High Efficiency: Many OBCs now achieve efficiency rates above 95%, reducing energy waste.

- Compact and Lightweight Design: Advanced materials and designs make OBCs less bulky, contributing to vehicle efficiency.

- Smart Charging: Integration with apps and smart home systems enables users to schedule and monitor charging sessions.

- Thermal Management Systems: Built-in cooling mechanisms prevent overheating, ensuring reliable performance.

- Wide Voltage Range: Support for multiple voltage levels allows for charging in different regions with varying power standards.

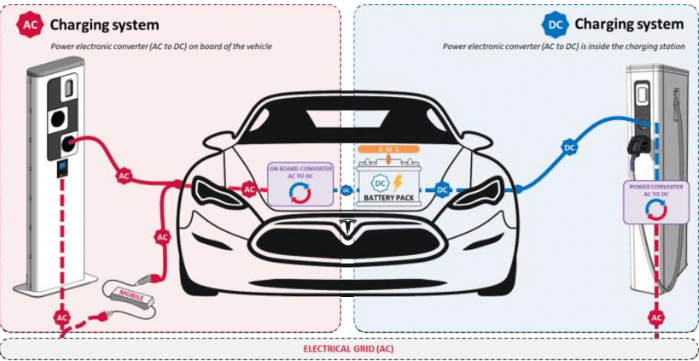

OBC vs. External Chargers: What’s the Difference?

The distinction between an OBC (On Board Charger) and an external charger is essential for understanding EV charging infrastructure:

|

Feature |

OBC (On Board Charger) |

External Charger |

|

Location |

Built into the EV |

Separate from the vehicle |

|

Function |

Converts AC to DC for battery charging |

Supplies AC or DC power to the EV |

|

Portability |

Always available in the vehicle |

Must be carried and set up |

|

Charging Speed |

Limited by OBC capacity |

Can support faster charging speeds |

|

Cost |

Included in vehicle price |

May require additional investment |

While OBCs are perfect for everyday charging, external chargers are often used for rapid charging at public stations.

Tips for Maintaining Your OBC

Maintaining your On Board Charger (OBC) is essential to ensure its efficiency, reliability, and longevity. Follow these tips to keep your OBC in optimal condition:

1. Use Compatible Chargers

Always charge your EV using power sources and chargers that meet the specifications outlined by the manufacturer. Using incompatible chargers can strain the OBC and potentially damage your vehicle's electrical system.

2. Inspect Regularly

Periodically check the charging ports and cables for any physical damage, dirt, or corrosion. Clean the ports gently to ensure proper electrical contact and prevent charging interruptions caused by debris or wear.

3. Monitor Charging Behavior

Be attentive to your vehicle’s charging behavior. Unusual signs such as slower charging times, strange noises, or error codes displayed on the dashboard may indicate a problem with the OBC that requires attention.

4. Install Updates

Keep your OBC firmware updated with the latest software provided by the manufacturer. Updates often include performance enhancements, new features, and fixes for known issues.

5. Consult Professionals

For any repairs or concerns about your OBC, consult certified EV technicians. Attempting to fix complex electrical components yourself may lead to further issues or void warranties.

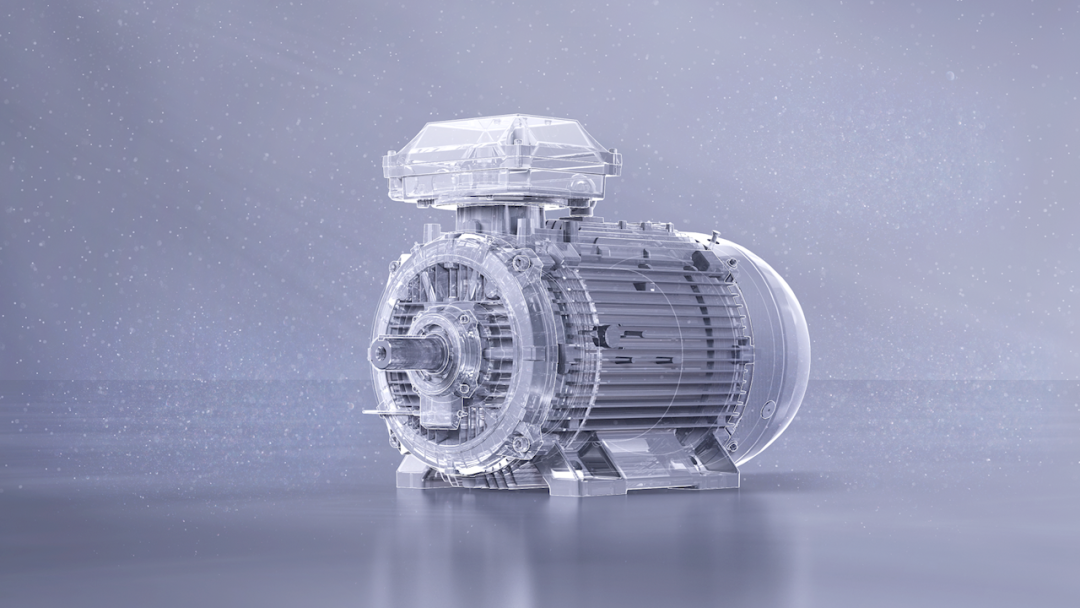

Selection of power devices for on-board OBCs

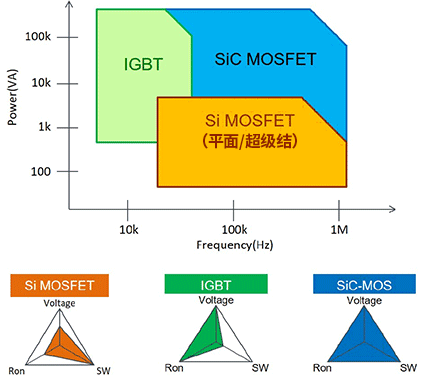

The on-board charger OBC is one of the key components that determine the charging power and efficiency of electric vehicles, and power semiconductors such as silicon-based high-voltage MOSFETs and IGBTs, SiC SBDs and SiC MOSFETs are the key components to realize the conversion of direct current and alternating current of OBC.

Comparison of Silicon Carbide MOSFETs, Silicon Super Junction MOSFETs and IGBTs

SiC MOSFETs are available for PFC, primary-side DCDC, and secondary-side rectification (bidirectional) and are recommended for 800VDC battery systems. This technology achieves the highest efficiency and power density compared to IGBTs or silicon superjunction MOSFETs. Among the many designs that use SiC MOSFETs, there may be hybrid solutions, i.e., IGBTs or silicon superjunction MOSFETs may also be used for some power stages of the OBC.

1. In a 400VDC battery system, the efficiency of SiC MOSFETs can be increased by 0.2% - 0.5% if traditional step-up or staggered-boost topologies are used; If used for primary-side DCDC or secondary-side rectification (bidirectional), power density and efficiency can be improved. Silicon carbide MOSFETs may deliver even greater benefits when they are used in higher power levels where efficiency is critical to reducing heat loads.

2. It is recommended to use 1200V SiC MOSFETs for 800VDC battery systems and 650V SiC MOSFETs for 400VDC battery systems. When using totem pole PFCs, silicon carbide MOSFET technology is a recommended solution for any battery voltage.

3. Silicon superjunction MOSFETs are available for PFC, primary-side DCDC, and secondary-side rectification (bidirectional). Silicon superjunction MOSFETs work well for PFC in traditional boost, bridgeless boost, and Vienna rectifier designs, but not as well when used in totem-pole PFCs. The disadvantages of hard-switching totem pole PFCs are the reverse recovery losses of the body diode and the inability to operate in continuous conduction mode. Compared to IGBTs, silicon superjunction MOSFETs have higher switching speeds and efficiency. For OBC cells with a nominal voltage of 400VDC, 650V silicon superjunction MOSFETs are ideal for primary and secondary rectification in bidirectional designs.

IGBTs do not have a built-in body diode, and need to package a diode inside or connect an external diode in parallel. The hybrid IGBT contains a silicon carbide diode in the package.

1. For PFCs, IGBTs can be used in most topologies and can be used for "low-speed" tubes of totem pole PFCs, even if other techniques are used for "high-speed" tubes. When considering the cost of primary-side DCDC conversion, IGBTs can be used in designs with lower power levels.

2. Slower switching speeds and lower efficiencies will have to be within the acceptable range of the design compared to silicon superjunction MOSFETs or silicon carbide MOSFETs. IGBTs can also be used for secondary-side rectification in low-power bidirectional designs, but are not commonly used due to high switching losses (compared to silicon superjunction or silicon carbide MOSFETs).

3. Comparison of silicon diodes and silicon carbide diodes: Silicon diodes can be used for OBC PFC stage and secondary-side rectification (unidirectional design) in 400V battery systems. Silicon carbide diodes are ideal for 800V battery systems due to their high power density, high voltage ratings, and no reverse recovery losses. SiC diodes can also operate at lower voltages for increased efficiency.

Conclusion

The OBC (On Board Charger) is a cornerstone of electric vehicle technology, enabling efficient and safe battery charging. Its ability to convert, regulate, and monitor energy flow ensures EV owners can rely on their vehicles for daily use and long journeys.

Improving energy efficiency requires the help of new semiconductor materials such as WBG power devices. Bidirectional OBC for the automotive industry, for example, combines the benefits of new materials in applications, including improved power efficiency, reduced size, reduced weight, and lower overall cost, while supporting innovative green energy use cases such as V2G. As the world's leading supplier of OBC and supporting technologies, PUMBAA EV is working with its customers to create a greener and more sustainable future.

Read More: What Is a DC/DC Converter in Electric Vehicles