PMSM Motor for EV: Why It is the Perfect Option?

The electric vehicle (EV) industry is evolving at an accelerated pace, driven by the need for cleaner, more sustainable transportation options. One of the most critical components enabling this shift is the motor, which plays a pivotal role in determining a vehicle’s performance, efficiency, and driving experience. Among the various types of motors available, the PMSM motor for EV has emerged as a frontrunner due to its numerous advantages, making it the perfect choice for modern electric vehicles. This blog will explore the reasons why PMSM motors are an ideal option for EVs, focusing on their features, benefits, technological advancements, and applications.

Introduction

The electric vehicle market is undergoing a revolution. As environmental concerns continue to rise, more consumers and businesses are turning to electric vehicles (EVs) as an alternative to traditional combustion-engine cars. At the heart of every electric vehicle is the motor, a crucial component that determines not only how the vehicle drives but also its energy efficiency and performance.

Among the various motor types used in EVs, the PMSM motor for EV has gained significant attention due to its exceptional performance characteristics. Permanent Magnet Synchronous Motors (PMSMs) offer several advantages over traditional internal combustion engines and other motor types like induction motors. This blog aims to delve deeper into what makes PMSM motors a superior choice for EVs, exploring their technical features, benefits, and applications, while also addressing some frequently asked questions.

What is a PMSM Motor?

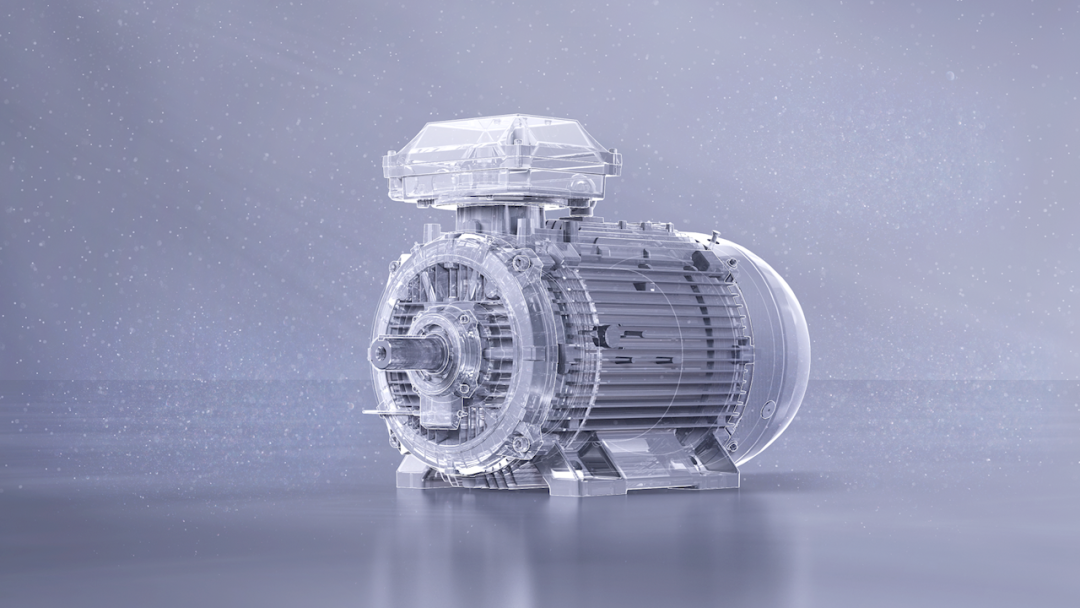

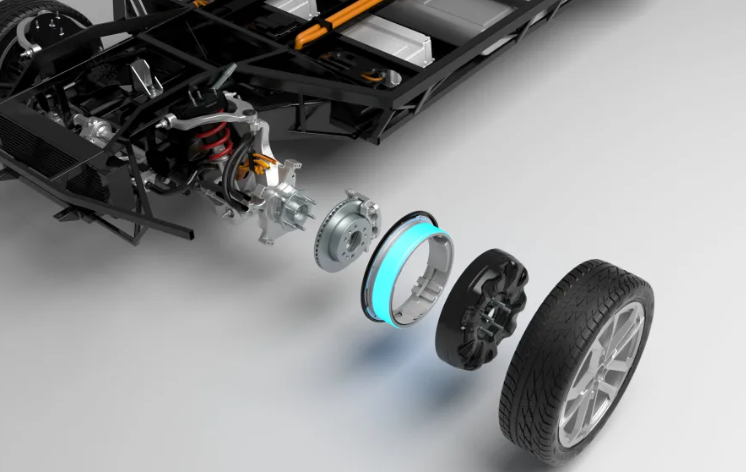

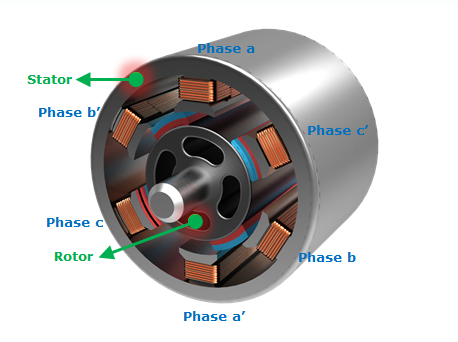

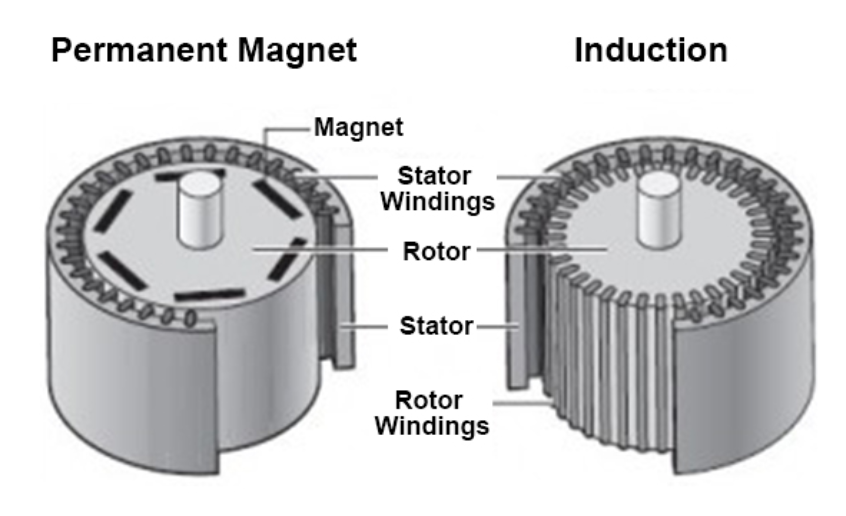

A Permanent Magnet Synchronous Motor (PMSM) is a type of synchronous motor that uses permanent magnets embedded in the rotor to create a magnetic field. This differs from induction motors, which rely on electromagnetic induction to generate the magnetic field. In PMSMs, the rotor's magnetic field is constantly synchronized with the stator’s rotating magnetic field, allowing the motor to operate with high efficiency and minimal energy loss.

Key Components of a PMSM Motor:

- Stator: The stator is the stationary part of the motor that contains coils of wire. These coils are powered by alternating current (AC) to generate a rotating magnetic field. The stator is essential for generating the motor’s torque.

- Rotor: The rotor is the rotating part of the motor and contains permanent magnets. These magnets interact with the stator’s magnetic field to produce torque. The rotor is driven by the electromagnetic force created by the stator.

- Controller: The controller regulates the current flow to the stator windings, controlling the motor's speed and torque. It ensures that the rotor remains synchronized with the stator’s magnetic field.

This configuration enables PMSM motors to offer high efficiency, reliability, and power density, making them ideal for electric vehicles.

Key Features of PMSM Motors

PMSM motors come with a range of features that make them particularly suitable for EV applications. These include:

- High Power Density: PMSM motors are known for their high power output relative to their size. This allows for compact and lightweight motor designs, which is a critical factor for EVs where space and weight are often at a premium. By using high-performance magnets, PMSMs can generate more power with less material, which is ideal for electric vehicles that require powerful yet compact motors.

- Efficient Performance: One of the most significant advantages of PMSMs is their high efficiency. PMSMs can achieve efficiency levels of up to 95% or more, significantly reducing energy losses. This high efficiency translates to less battery consumption, longer driving ranges, and better overall performance in EVs.

- Smooth Operation: PMSM motors provide a smooth, continuous flow of power with minimal vibration or noise. This makes them ideal for passenger vehicles where comfort and noise reduction are essential. Their smooth operation contributes to a better driving experience, especially in urban environments with frequent stops and starts.

- Wide Speed Range: PMSMs can operate efficiently across a broad range of speeds. This is essential for EVs, which require flexibility to handle both low-speed urban driving and high-speed highway driving. PMSMs maintain their efficiency and torque output across these varying speeds, making them highly versatile.

- Durability: The robust construction of PMSM motors ensures a long operational lifespan. These motors are built to withstand the wear and tear of everyday driving and require minimal maintenance. The absence of brushes, which are present in some other motor types, further reduces the risk of mechanical failure.

Advantages of PMSM Motors in EV Applications

The advantages of PMSM motors for EVs are manifold, and they directly contribute to the growing adoption of these motors in the automotive industry. Below are some key benefits:

1 High Efficiency

PMSMs are among the most efficient electric motors available. The use of permanent magnets reduces energy loss during the conversion of electrical energy to mechanical energy. This is especially important in EVs, where maximizing energy efficiency is essential for increasing the driving range. With PMSMs, energy consumption is minimized, allowing EVs to travel further on a single charge.

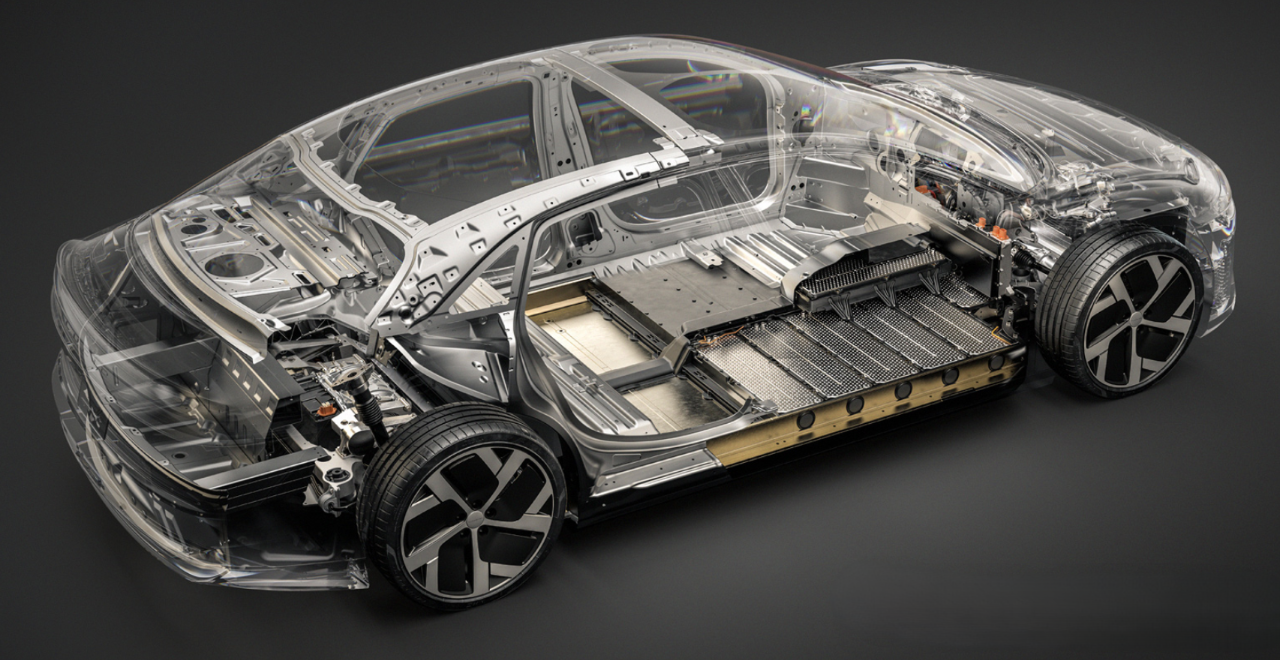

2 Compact and Lightweight

Due to their high power density, PMSM motors are relatively compact and lightweight compared to other motor types, such as induction motors. This compactness is a significant advantage for electric vehicles, as it allows manufacturers to design more space-efficient vehicles. Moreover, reducing the weight of the motor helps improve the overall efficiency of the EV by reducing the amount of energy required to move the vehicle.

3 Excellent Torque Characteristics

PMSMs are known for their excellent torque characteristics, particularly at low speeds. This is particularly beneficial for EVs, where smooth acceleration and deceleration are key to providing a comfortable driving experience. The high torque output at low speeds also enhances the EV’s performance in stop-and-go traffic, which is typical in urban environments.

4 Low Maintenance

PMSMs have fewer moving parts compared to other motor types. They do not require brushes or slip rings, which reduces the need for regular maintenance and the risk of mechanical wear. This translates to lower maintenance costs and less downtime for EVs, making them more reliable and cost-effective in the long run.

5 Regenerative Braking Compatibility

PMSMs are well-suited for regenerative braking, a key feature of electric vehicles. During braking, the motor can act as a generator, converting kinetic energy back into electrical energy, which is then stored in the battery. This process improves the overall energy efficiency of the EV and helps extend the driving range.

6 Superior Thermal Management

PMSMs are designed to generate less heat than other types of motors, thanks to their high efficiency and robust construction. Effective thermal management is crucial for maintaining the performance and longevity of the motor, especially in EVs that operate in various temperature conditions. PMSMs can handle higher power outputs without overheating, ensuring optimal performance in both cold and hot environments.

Technological Advancements in PMSM Motors

The continuous evolution of PMSM motor technology has further enhanced its performance and suitability for EV applications. Here are some of the key advancements:

1 Enhanced Magnet Materials

The development of advanced magnet materials, such as neodymium-based magnets, has significantly improved the power density and efficiency of PMSM motors. These high-performance magnets allow for smaller, lighter motors that can generate more torque, making them ideal for EVs.

2 Improved Cooling Techniques

Efficient cooling systems are crucial for maintaining the performance of PMSMs, especially at higher power levels. Advanced liquid cooling and air cooling techniques have been integrated into PMSM designs to ensure that the motor remains at an optimal temperature during operation. These cooling systems help prevent overheating and improve the overall efficiency and lifespan of the motor.

3 Advanced Control Algorithms

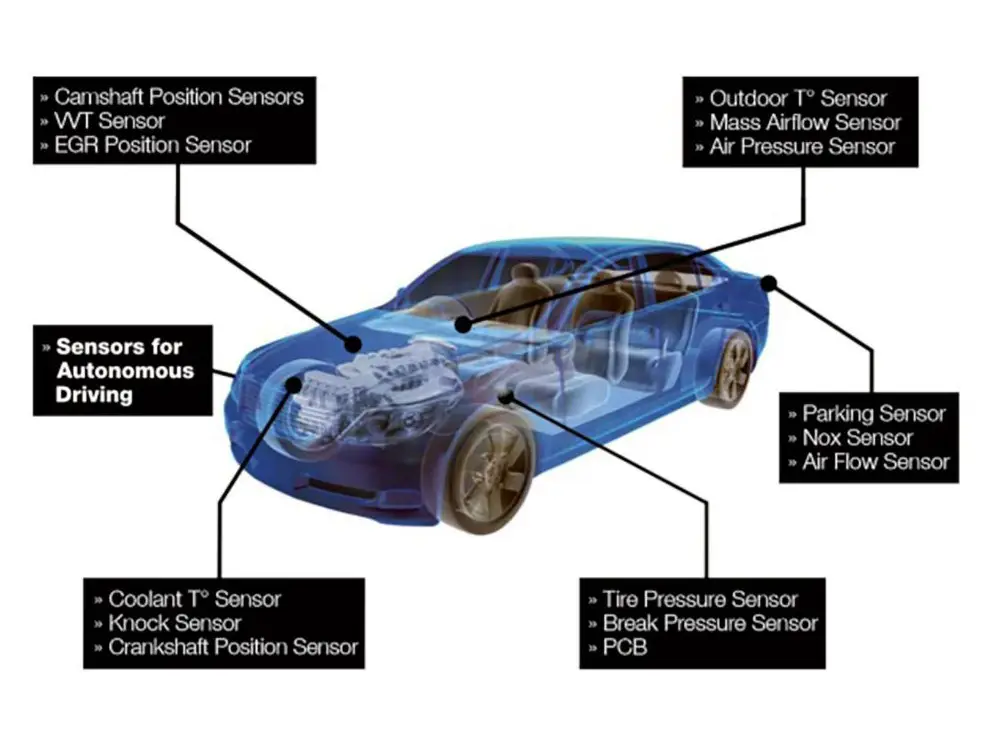

Modern PMSM motors are equipped with advanced control algorithms that optimize their performance in real-time. These algorithms adjust the motor’s speed, torque, and efficiency based on the driving conditions, ensuring smooth operation and maximum energy efficiency.

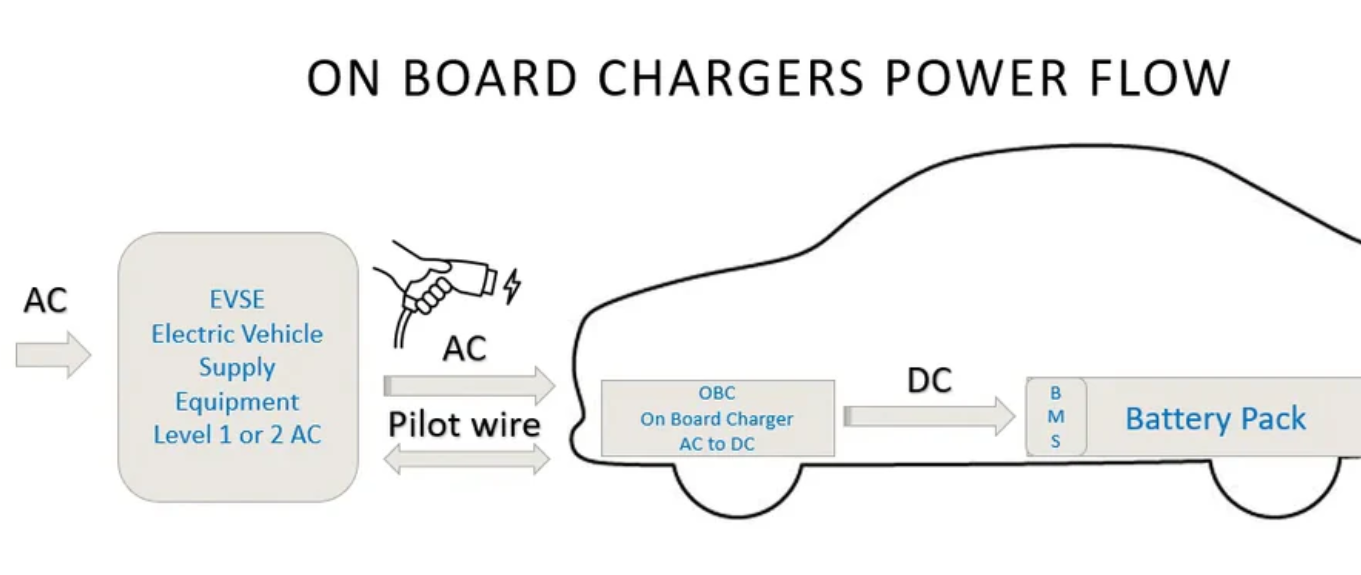

4 Integration with Inverters

PMSM motors are often integrated with high-efficiency inverters that convert direct current (DC) from the battery into alternating current (AC) to power the motor. This integration reduces energy losses and improves the overall efficiency of the powertrain, ensuring that the EV performs optimally under different driving conditions.

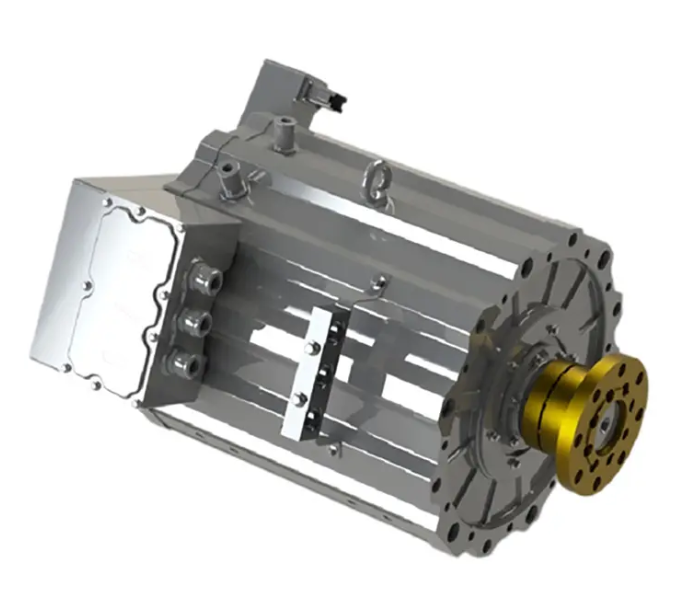

5 Modular Designs

Modular PMSM designs are becoming more common, allowing manufacturers to create scalable and customizable motors for various EV applications. This flexibility reduces production costs and enables easier maintenance, as components can be replaced or upgraded without needing to replace the entire motor.

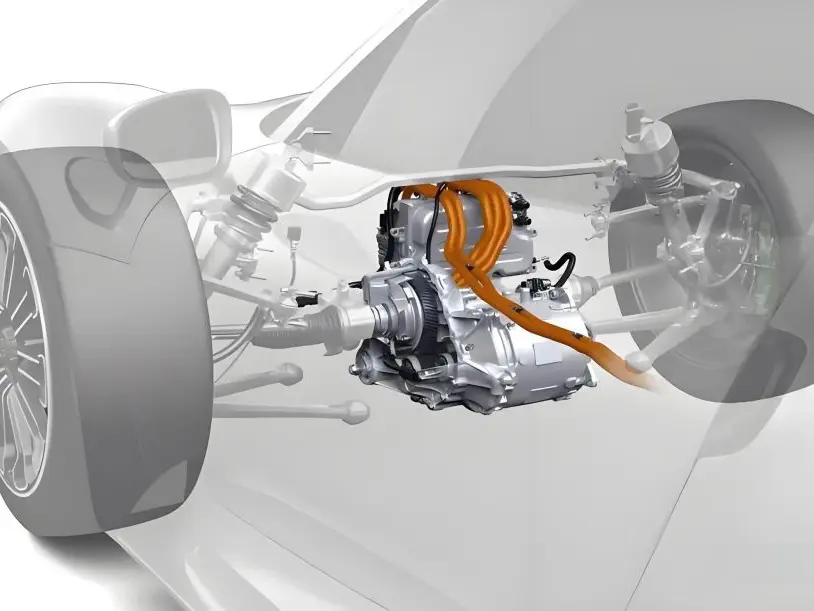

Applications of PMSM Motors in EVs

PMSM motors are used in a wide range of electric vehicles, including:

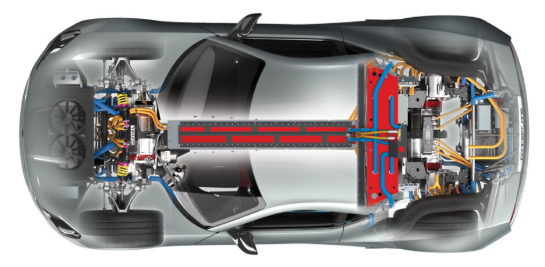

1 Passenger Cars

Most modern electric cars, including popular models from Tesla, Nissan, and Chevrolet, use PMSM motors for their excellent efficiency and performance. These motors help improve the driving range and provide smooth, quiet acceleration.

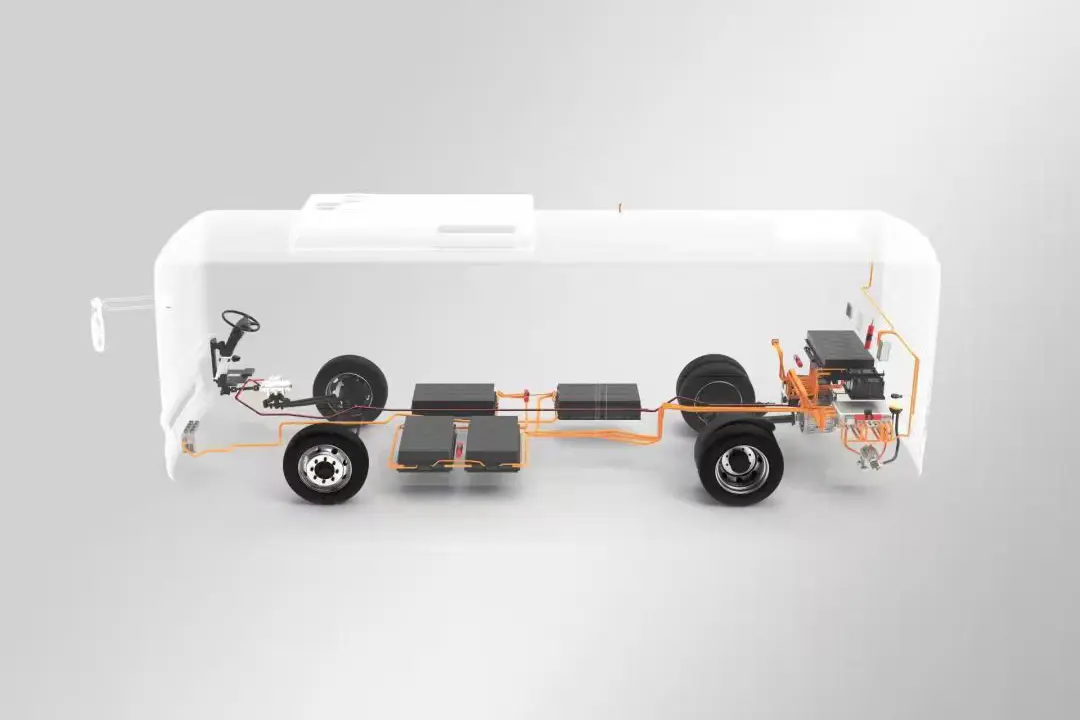

2 Electric Buses

Electric buses benefit from the high torque and efficiency of PMSMs, allowing them to carry heavy loads while maintaining optimal energy consumption. The smooth operation of PMSMs also reduces noise pollution, which is important in urban environments.

3 Commercial EVs

From delivery vans to light-duty trucks, PMSMs are used in a variety of commercial EVs. Their efficiency and reliability make them well-suited for businesses looking to reduce operating costs and environmental impact.

4 Two-Wheelers

Electric scooters and motorcycles use PMSM motors for their lightweight design and high torque output. These motors allow for quick acceleration and efficient energy usage, making them ideal for urban commuting.

5 Hybrid Vehicles

In hybrid vehicles, PMSMs work in tandem with internal combustion engines to optimize fuel efficiency. They provide power during low-speed driving and assist in regenerative braking, contributing to improved overall energy management.

FAQs about PMSM Motors for EVs

Q1: Why are PMSM motors preferred over induction motors for EVs?

PMSM motors offer higher efficiency, reduced energy loss, and better torque characteristics at low speeds compared to induction motors. Additionally, PMSMs are more compact and require less maintenance, making them more suitable for EVs.

Q2: What is the lifespan of a PMSM motor in an EV?

With proper maintenance, PMSM motors can last for several decades. They are built to be durable and require minimal upkeep due to the lack of brushes and slip rings.

Q3: Are PMSM motors expensive to manufacture?

The manufacturing cost of PMSM motors can be higher due to the use of rare-earth magnets, but their long-term benefits, such as efficiency and reduced maintenance, offset the initial cost.

Q4: Can PMSM motors be used in all types of EVs?

Yes, PMSM motors are versatile and can be used in passenger cars, buses, trucks, two-wheelers, and hybrid vehicles.

Q5: How do PMSM motors contribute to the range of an EV?

PMSMs reduce energy consumption and maximize efficiency, allowing EVs to travel longer distances on a single charge.

Conclusion

The PMSM motor for EV is undeniably the perfect choice for electric vehicles. Its superior efficiency, compact design, high torque characteristics, and durability make it the ideal motor for a wide range of EV applications. As the EV industry continues to grow and evolve, PMSM motors will remain at the forefront of this technological revolution, contributing to the development of more efficient, reliable, and sustainable electric vehicles. For both automakers and consumers, the PMSM motor offers a glimpse into the future of transportation—one that is greener, cleaner, and more efficient.

Read More: Top 10 EV Motor Suppliers in China