Why We Use EV DC/DC Converter in Electric Vehicles

Introduction

Electric vehicles (EVs) are transforming the landscape of modern transportation. They offer cleaner alternatives to internal combustion engine vehicles, with reduced emissions, lower operational costs, and improved energy efficiency. However, the move to electrification brings unique engineering challenges, especially in managing electrical power within the vehicle. Among the vital components enabling EV functionality is the EV DC/DC converter.

Although not as publicly celebrated as batteries or electric motors, the EV converter is fundamental to a well-functioning EV system. It ensures seamless interaction between the high-voltage propulsion battery and the low-voltage systems that control everything from dashboard lights to safety features.

In this blog, we’ll take a deep dive into what EV DC/DC converters are, why they're necessary, how they work, their types, benefits, challenges, and where innovation is headed in this space.

Understanding EV DC/DC Converters

To appreciate the value of an EV DC/DC converter, it’s essential to first understand its role in power management.

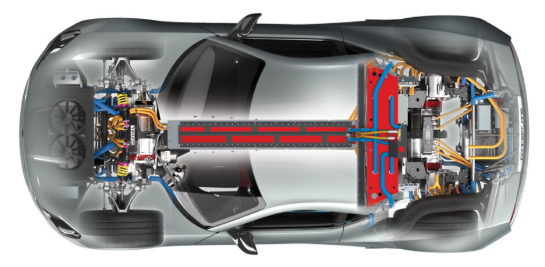

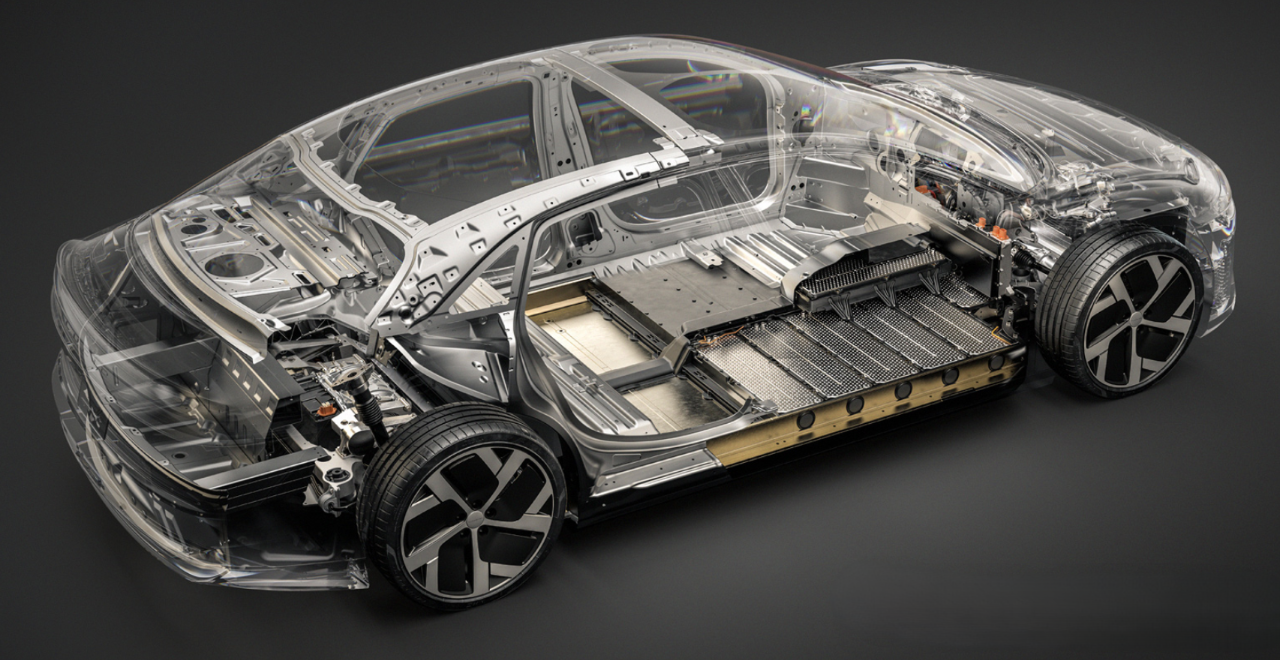

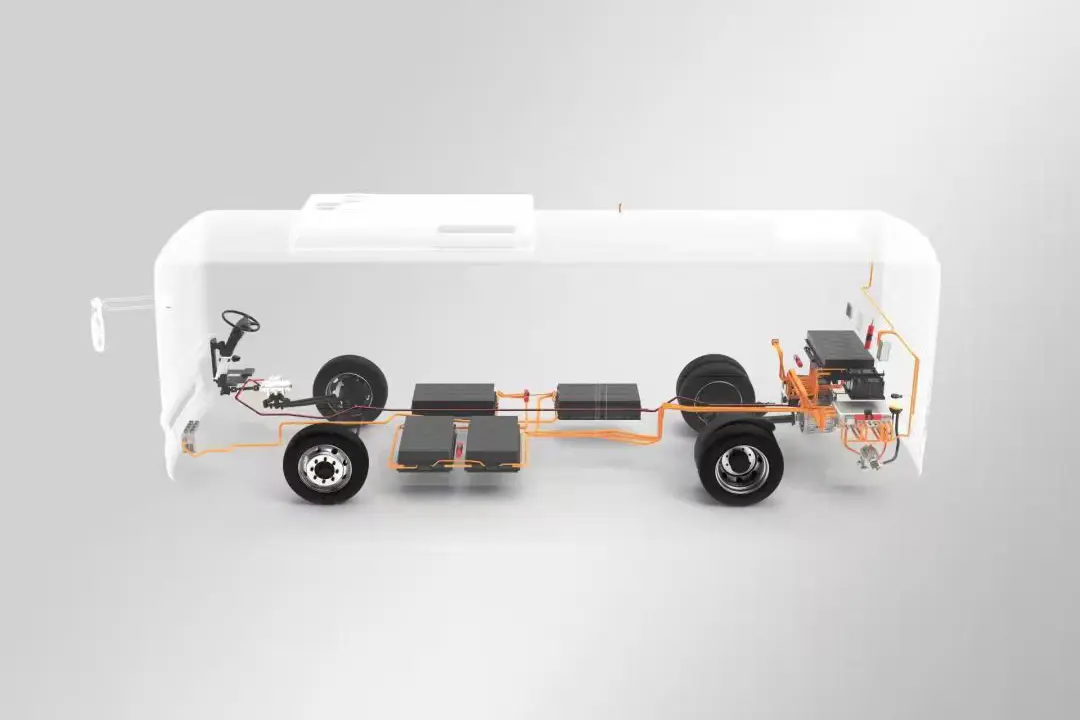

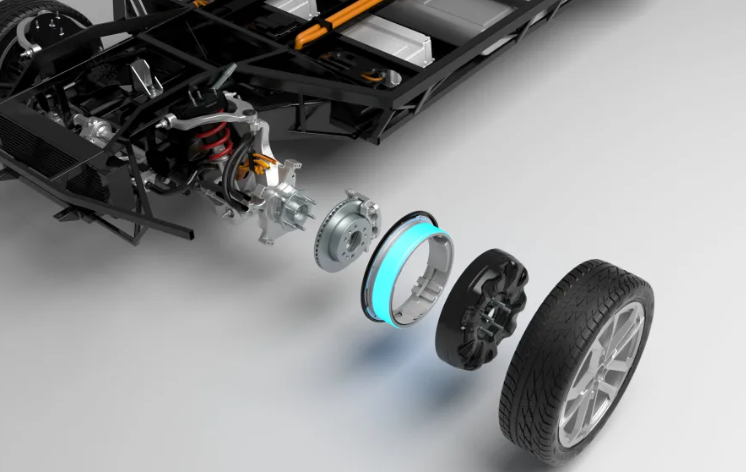

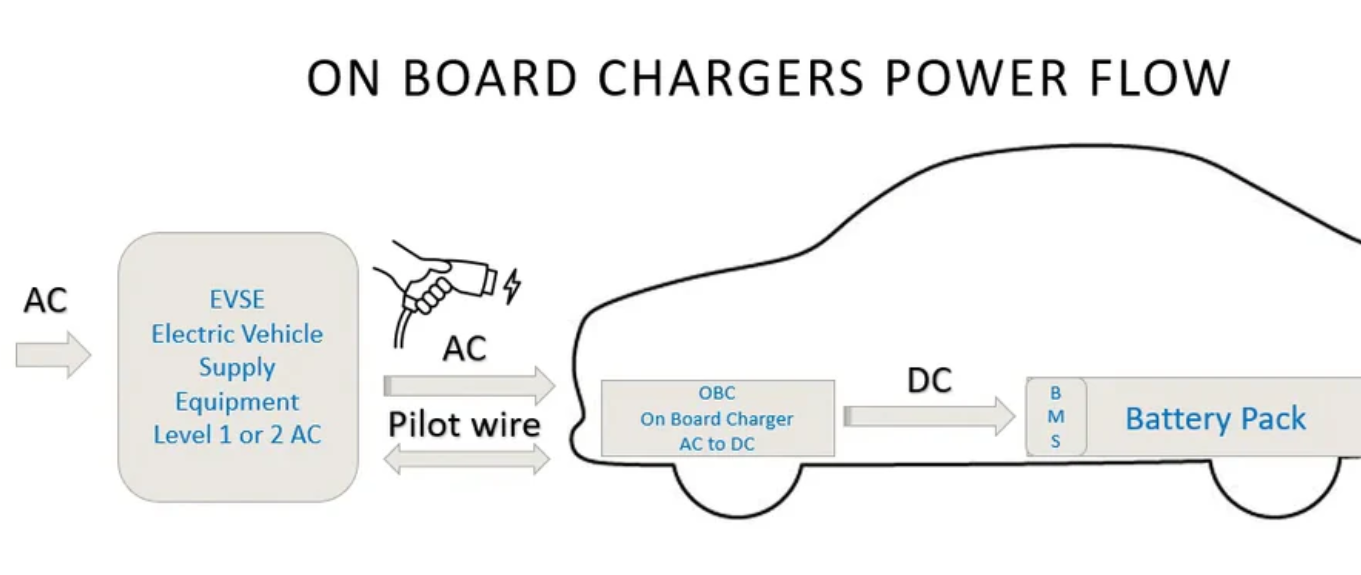

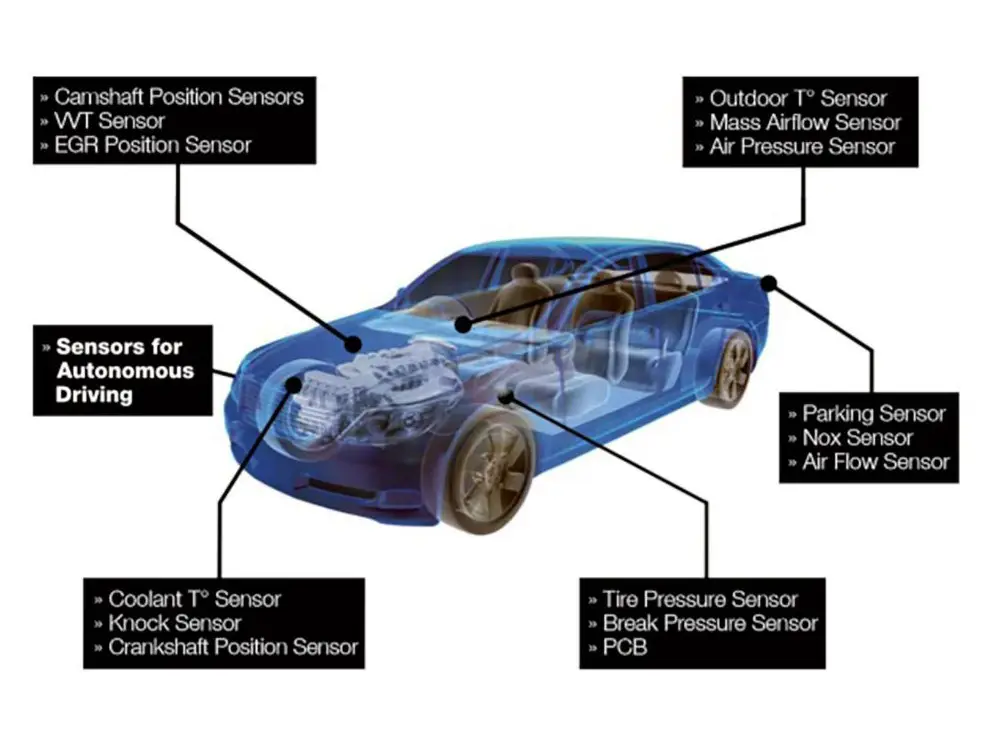

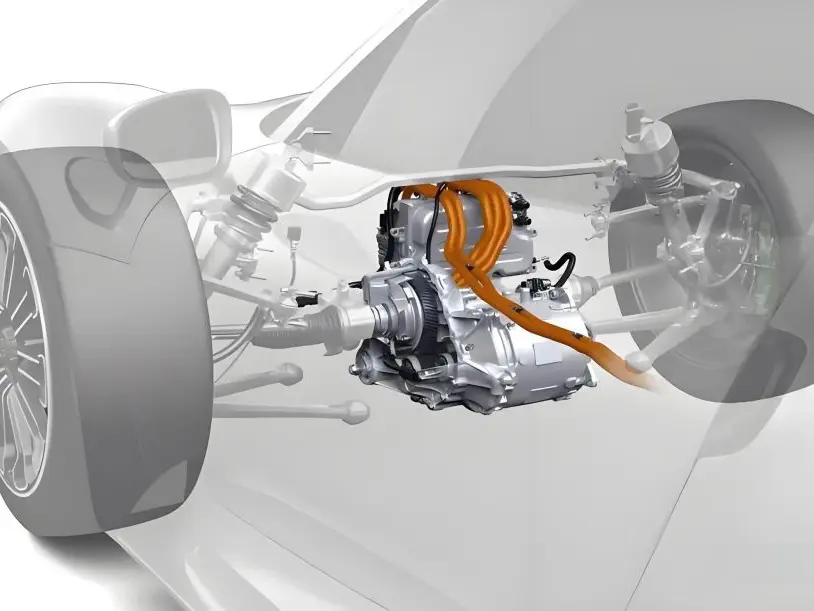

EVs are equipped with a high-voltage battery system (typically between 200V and 800V), which is mainly used to power the electric motor and drive system. However, many vehicle systems—such as the infotainment unit, power steering, air conditioning, lights, and vehicle control units—run on a traditional 12V or sometimes 48V system. Directly connecting these components to a high-voltage battery would be unsafe and inefficient.

This is where the EV converter comes in. It steps down the voltage from the high-voltage battery pack to a lower, stable voltage level that low-voltage components can safely use. The EV DC/DC converter is thus responsible for ensuring a reliable power supply across all vehicle systems, acting as a bridge between high and low-voltage domains.

Some converters can also function in reverse—stepping voltage up or managing bidirectional energy flow for systems like regenerative braking and vehicle-to-grid (V2G) technologies.

Why EVs Need DC/DC Converters

Electric vehicles consist of a complex ecosystem of electrical components with diverse power requirements. Without an EV DC/DC converter, synchronizing these systems would be nearly impossible. Let’s look at the primary reasons these converters are indispensable:

a. High-Voltage to Low-Voltage Conversion

The most basic requirement is to convert the high-voltage from the traction battery to a safer 12V or 48V. This conversion powers low-voltage systems essential for safety, comfort, and communication.

b. Auxiliary Battery Charging

EVs still include a traditional 12V lead-acid or lithium-ion battery to power systems when the car is off or during startup. The EV converter keeps this auxiliary battery charged by drawing energy from the main battery.

c. Reduced Component Complexity

By centralizing voltage conversion, DC/DC converters reduce the need for multiple power sources and help streamline the vehicle’s electrical architecture.

d. Safety and Isolation

Converters often include galvanic isolation, which protects users and sensitive electronics from potential high-voltage faults.

e. Emergency Power Supply

In scenarios like battery failure or low charge, a DC/DC converter can continue to supply essential low-voltage components, such as lights or emergency signaling systems, ensuring driver and passenger safety.

Key Functions of DC/DC Converters in EVs

The functionality of an EV DC/DC converter goes well beyond simply reducing voltage. These devices support a wide array of critical tasks:

a. Voltage Step-Down (Buck Conversion)

The primary job of the converter is to step down the voltage from hundreds of volts to a usable 12V or 48V. This powers electronics like:

- Window regulators

- Door lock actuators

- Windshield wipers

- Electronic control units (ECUs)

b. Voltage Regulation and Stabilization

Even as the traction battery depletes or the load on the system changes, the converter ensures that low-voltage systems receive a constant and clean supply of power.

c. Isolation Between Systems

In isolated converters, the input and output sides are electrically separated. This prevents faults in one domain from affecting the other—improving system resilience and safety.

d. Auxiliary Battery Management

By controlling the flow of energy from the main battery to the auxiliary battery, the converter ensures that it remains charged and ready to power critical systems like keyless entry, alarm systems, and control modules.

e. Diagnostic and Monitoring Capabilities

Advanced converters can monitor voltage levels, temperature, current draw, and report anomalies. They may be integrated with vehicle onboard diagnostics (OBD) to alert users of issues before they escalate.

Types of DC/DC Converters in Electric Vehicles

There are different types of DC/DC converters used in electric vehicles based on function, level of isolation, and direction of energy flow.

a. Isolated DC/DC Converters

These have electrical isolation between the input and output, usually via a transformer. They are safer but tend to be more complex and expensive.

Key characteristics:

- Enhanced safety

- Suitable for battery charging and isolated subsystems

- Higher cost and complexity

b. Non-Isolated DC/DC Converters

These lack isolation but are simpler, smaller, and more efficient for applications where electrical separation isn’t required.

Key characteristics:

- Compact design

- High efficiency

- Limited use where safety isolation is needed

c. Bidirectional DC/DC Converters

These allow energy flow in both directions, critical for regenerative braking and emerging technologies like V2G and vehicle-to-load (V2L).

Key characteristics:

- Two-way power flow

- Enables energy recovery

- Supports emerging EV-grid integrations

Each type of EV converter plays a specific role in the vehicle, depending on its configuration and powertrain design.

Advantages of Using DC/DC Converters in EVs

Integrating a reliable EV DC/DC converter brings several advantages to vehicle performance, safety, and user experience:

a. Energy Efficiency

High-quality converters minimize conversion losses, ensuring that energy from the battery is used effectively across all systems. This translates to improved range and reduced battery wear.

b. Compact Vehicle Design

Instead of using separate power supplies, one centralized converter can distribute power throughout the vehicle. This reduces component redundancy and allows for a more compact vehicle design.

c. Safety Assurance

Converters isolate sensitive low-voltage components from high-voltage areas, reducing risk in the event of a short circuit or system failure.

d. System Reliability and Redundancy

With built-in protection features such as overcurrent protection, thermal shutdown, and fault detection, DC/DC converters enhance system durability.

e. Support for Smart Features

Some advanced converters can communicate with the central vehicle controller, adjusting output dynamically based on load, temperature, or operational mode.

Challenges and Considerations in DC/DC Converter Design

While EV DC/DC converters offer immense benefits, they also present several design challenges that manufacturers must address:

a. Managing Heat Dissipation

High-power converters generate significant heat. If not properly managed, this can lead to reduced efficiency and early failure.

Design response: Use of heat sinks, thermal paste, forced air cooling, or even liquid-cooled converter enclosures.

b. Maintaining High Efficiency

As converters work under varying loads and environmental conditions, maintaining high efficiency across the entire operating range is difficult.

Solution: Use of wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN) to reduce switching losses and increase performance.

c. Electromagnetic Interference (EMI)

Switching components inside converters can produce EMI, which may interfere with nearby electronics, including critical vehicle systems.

Mitigation: Careful PCB layout, shielding, and the inclusion of EMI filters help keep emissions within regulatory limits.

d. Cost vs. Performance Tradeoffs

High-performance converters with advanced features and isolation tend to be more expensive. Finding a balance between functionality and cost is essential for mass adoption.

Future Trends and Innovations in EV DC/DC Converters

As EV technology continues to evolve, EV DC/DC converters are also undergoing rapid innovation:

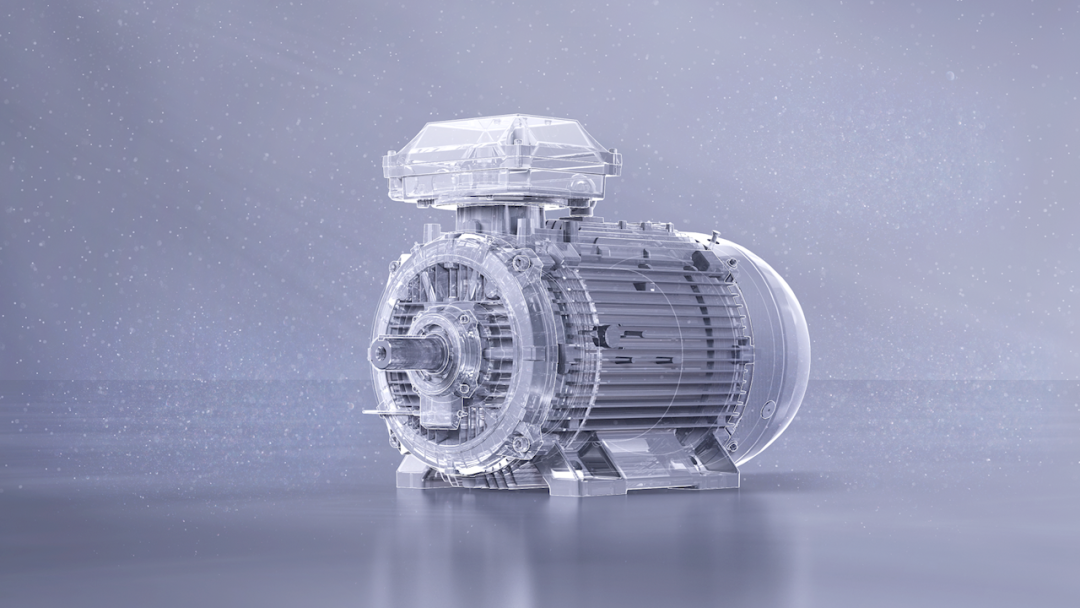

a. Wide Bandgap Materials (SiC, GaN)

These materials allow higher switching frequencies, better thermal performance, and increased efficiency—leading to smaller, lighter converters.

b. Integrated Power Electronics

Instead of separate inverters, converters, and chargers, manufacturers are developing integrated power modules that handle multiple functions in a single unit.

c. AI and Smart Controls

With AI and digital control loops, converters can adapt to changing loads and optimize performance in real-time, improving overall energy management.

d. Modular Architecture

Future EV platforms are expected to use modular DC/DC converters, making it easier to scale up or down depending on vehicle requirements.

e. Bidirectional Energy Flow

Next-generation vehicles will increasingly use bidirectional converters to support grid services, home energy supply (V2H), and energy trading.

Conclusion

The EV DC/DC converter is more than just a voltage regulator—it’s a crucial component that enables electric vehicles to function safely, efficiently, and reliably. As EVs become more complex and integrated into smart grids and digital ecosystems, the role of the EV converter becomes even more critical.

From powering essential 12V systems to enabling bidirectional energy flow, the DC/DC converter ensures that energy is distributed where and when it’s needed. It allows for lightweight, space-saving designs and supports the smart electrification of transport.

In the future, innovations in material science, power electronics, and software control will make EV converters even more compact, efficient, and intelligent. Whether you’re an EV designer, fleet manager, or simply an EV owner, understanding the importance of DC/DC converters provides insight into the invisible yet vital tech driving electric mobility forward.

Read More: Increasing Electric Vehicle Adoption is Propelling the Market Expansion