Electric Car Engine Conversion Kit Guide: Can I Get My Car Converted to Electric?

Introduction

As electric vehicles (EVs) become more popular, many drivers are exploring the option of converting their internal combustion engine (ICE) vehicles to electric power. An electric car conversion offers an eco-friendly alternative to buying a new EV, making it a compelling option for car enthusiasts, those with classic cars, or people looking to reduce their environmental impact. This guide explains the key aspects of an electric car engine conversion kit, the conversion process, costs involved, and whether it’s worth the investment.

What is an Electric Car Engine Conversion Kit?

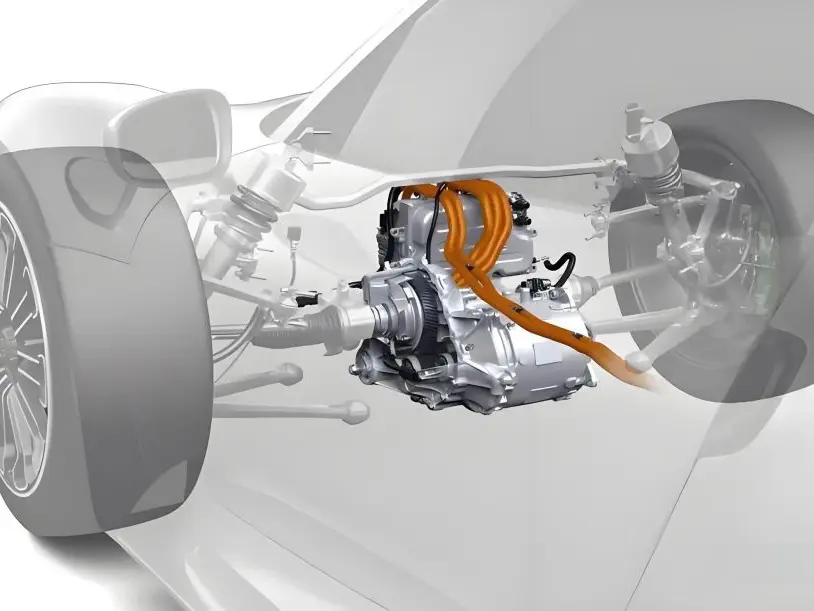

An electric car engine conversion kit is a collection of parts that allows you to replace your gasoline-powered engine with an electric motor and battery system. These kits typically include essential components like an electric motor, battery pack, controller, and other necessary parts to convert a car to electric power. By removing the traditional engine and installing these electric components, you can turn a gas-powered vehicle into a fully electric one.

Components of an Electric Car Engine Conversion Kit

1. Electric Car Motor: Provides the torque and power needed to drive the vehicle. DC or AC motors are the most commonly used. AC motors are typically more efficient and powerful.

2. Battery Pack: Stores the electricity that powers the motor. Usually lithium-ion batteries are preferred for their efficiency and longevity.

3. EV Motor Controller: Regulates the power from the battery to the motor, allowing for smooth acceleration. This device controls the flow of electricity from the battery to the motor based on your throttle input.

4. Charger: Used to recharge the battery pack, typically from home outlets or dedicated EV chargers.

5. DC-DC Converter: Converts the high-voltage battery power to lower voltage to power the car’s electrical systems (lights, radio, etc.).

6. Mounting Hardware and Wiring: These parts ensure the new components fit securely and function correctly within the vehicle.

PUMBAA power conversion & distribution for electric vehicles PPs500

PUMBAA power conversion & distribution for electric vehicles PPs500

Why Consider an Electric Car Conversion?

Environmental Impact

Converting a car to electric significantly reduces carbon emissions. Electric vehicles emit zero tailpipe emissions, making them cleaner for the environment. This is especially important as many regions are pushing for greener alternatives in transportation.

Cost Savings and Fuel Efficiency

Over time, electric vehicles are cheaper to operate than traditional gas-powered cars. Electricity is generally less expensive than gasoline, and since EVs have fewer moving parts, they require less maintenance. The savings on fuel and reduced repair costs can make the initial conversion investment worthwhile.

Enhanced Driving Performance

Electric motors provide immediate torque, meaning better acceleration and a smoother driving experience. The quiet operation of electric cars also enhances comfort while driving.

Types of Electric Conversion Kits

Universal Kits

These kits are designed to fit a wide variety of vehicle models. While versatile, universal kits might require more customization during installation to suit your specific car.

Custom Kits

Custom kits are tailored to specific car models. These kits provide a more seamless installation process and are often more efficient, but they can come at a higher price.

What is the Electric Car Conversion Kit Price

EV conversion kits typically cost between $5,000 and $10,000, with higher-end options offering more powerful motors and larger battery capacities.

For a reliable and high-quality solution, Pumbaa EV stands out as a leading manufacturer in the industry. They offer a complete range of products necessary for electric vehicle conversions, including:

· Electric Motors: High-efficiency motors designed for various vehicle types.

· Vehicle Control Unit (VCU): Ensures seamless integration and control of different systems within the car.

· Motor Controller: Regulates power between the battery and motor, allowing smooth acceleration and optimal performance.

· Power Conversion & Distribution Unit (CDU): Manages the distribution of electrical power across different components efficiently.

With Pumbaa EV’s expertise, you can expect competitive Electric Car Conversion Kit prices without compromising quality, making it easier than ever to switch from internal combustion engines to eco-friendly electric power. For exact pricing, it’s recommended to contact Pumbaa EV directly, as costs may vary based on customization and vehicle needs.

PUMBAA Electric Vehicle Motor Controller Unit(MCU)PMC20A

How Much Does It Cost to Convert a Car to Electric?

The cost of converting a car to electric varies significantly depending on the type of kit, labor, and components used. On average, the cost ranges from $6,000 to $20,000. Here's a breakdown:

1. Electric Car Conversion Kit Price: The cost of a basic kit can range from $5,000 to $10,000. Higher-end kits with more powerful motors or larger battery packs can cost more.

2. Batteries: Batteries are the most expensive component of the conversion, typically costing between $1,000 and $3,000, depending on the desired range.

3. Labor: If you choose professional installation, labor costs can add another $1,000 to $5,000. DIY installations will save on labor but require more time and skill.

4. Additional Components: Other parts like adapters, wiring, and chargers can add an extra $1,000 to $2,000 to the total.

In general, while the upfront costs are high, the long-term savings on fuel and maintenance make it a worthy investment for many drivers.

Step-by-Step Guide to Converting a Car

Converting a gas-powered car to electric power involves multiple steps. Here is a simplified guide:

1. Remove the Gas Engine: The first step is to remove the internal combustion engine and any associated parts, such as the fuel system and exhaust.

2. Install the Electric Motor: The electric motor is mounted in place of the old engine, often using an adapter plate to connect it to the vehicle’s original transmission.

3. Install the Battery Pack: The batteries are placed in a secure location, often in the trunk or under the seats. Battery placement is crucial for maintaining balance and performance.

4. Connect the Controller: The controller is wired to both the motor and the battery pack, managing how much power is delivered to the motor based on driver input.

5. Wiring: Complete the electrical connections, including wiring for the charging system, and ensure all components are properly secured.

6. Testing and Calibration: Once the components are installed, you will need to test and calibrate the system to ensure everything works as expected.

DIY vs. Professional Installation

A DIY conversion can be a rewarding project for those with mechanical and electrical experience. However, it’s time-consuming and requires specialized tools and knowledge. The advantage of DIY is saving on labor costs, but the risk is that mistakes can be costly and dangerous.

Pros of DIY

· Lower Cost: No labor costs, and you can shop around for the best deals on parts.

· Customization: Full control over the process and components.

Cons of DIY

· High Complexity: Requires significant technical knowledge.

· Time-Consuming: A DIY project could take months to complete.

For those who prefer a hassle-free approach, hiring a professional installer ensures the job is done safely and correctly. Though more expensive, professional installations are often more reliable.

Legal and Registration Requirements

In most areas, converting a car to electric power requires compliance with local laws and regulations. After the conversion, the vehicle will need to pass a safety inspection to be roadworthy. Additionally, in some regions, converted vehicles must meet emissions standards, though these are generally easier to satisfy since electric vehicles produce no tailpipe emissions.

It’s important to consult your local Department of Motor Vehicles (DMV) or relevant authority to understand the specific legal requirements for your area.

Range and Performance Expectations For Electric Car Conversion

The range and performance of your converted electric vehicle will largely depend on the size of the battery pack and the efficiency of the motor. Typically, a basic conversion kit will offer a range of 60–100 miles per charge, while higher-end conversions with larger batteries can provide 200 miles or more. Performance, including acceleration and top speed, will also vary, but most conversions result in a smooth, quiet driving experience with plenty of torque for everyday driving.

FAQs For Electric Car Conversion

Q: How much does it cost to convert an engine to electric?

A: The cost ranges from $6,000 to $20,000, depending on the electric car conversion kit price, and labor involved.

Q: Is it worth converting a car to electric?

A: Converting a car to electric can be worth it if you’re looking to lower your carbon footprint, reduce fuel costs, and extend the life of an older vehicle. However, the initial investment is high, so it may not be financially viable for everyone.

Q: Can you swap an engine for an electric motor?

A: Yes, replacing a traditional gas engine with an electric motor is the core of an electric vehicle conversion. With the right kit and components, this swap is entirely feasible.

Q: How to add an electric motor to a car?

A: Adding an electric motor involves mounting it where the old engine was located, connecting it to the existing transmission or drivetrain, and wiring it to a battery pack and controller.

Q: How big of an electric motor is needed to power a car?

A: The size of the electric motor needed depends on the vehicle’s weight and desired performance. Typically, motors in the 50-100 kW range are sufficient for small to medium-sized vehicles, while larger vehicles may require more powerful motors.

Tips for Maximizing Conversion Efficiency

· Minimize Weight: Reducing the weight of the car can significantly improve range and efficiency.

· Battery Care: Properly maintaining and charging the battery will extend its life and improve performance.

· Driving Habits: Gentle acceleration and using regenerative braking where possible can help maximize battery life.

Comparing Conversion to Buying an Electric Vehicle

Conversion Pros

· Lower upfront cost for those who already own a car.

· Customizable to your preferences.

· Sustainable by repurposing an existing vehicle.

Conversion Cons

· Complex installation process.

· Limited range compared to new EVs.

· Potential legal and registration hurdles.

Buying an EV Pros

· Warranties and reliability from automakers.

· Latest technology and features.

· Higher range and performance.

Buying an EV Cons

· Higher purchase cost for new vehicles.

· Depreciation like any new car purchase.

Conclusion

Converting your car to electric is a great way to reduce emissions, save on fuel, and enjoy the benefits of electric driving. While the initial cost can be steep, the long-term savings and environmental benefits make it an appealing option for many. Whether you choose to undertake the project yourself or hire a professional, this guide should provide a clear understanding of what to expect in the process of converting a gas car to electric.