How an EV Charger Converter Optimizes Charging Speeds

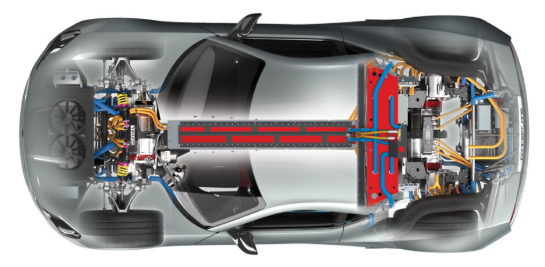

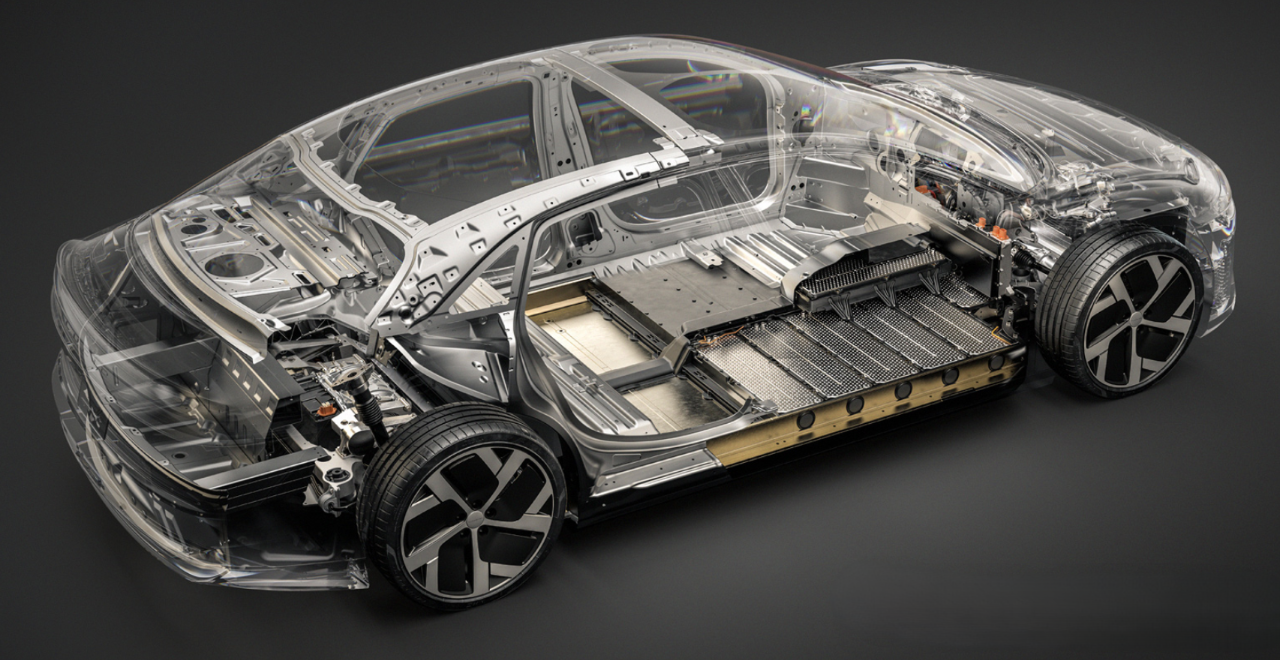

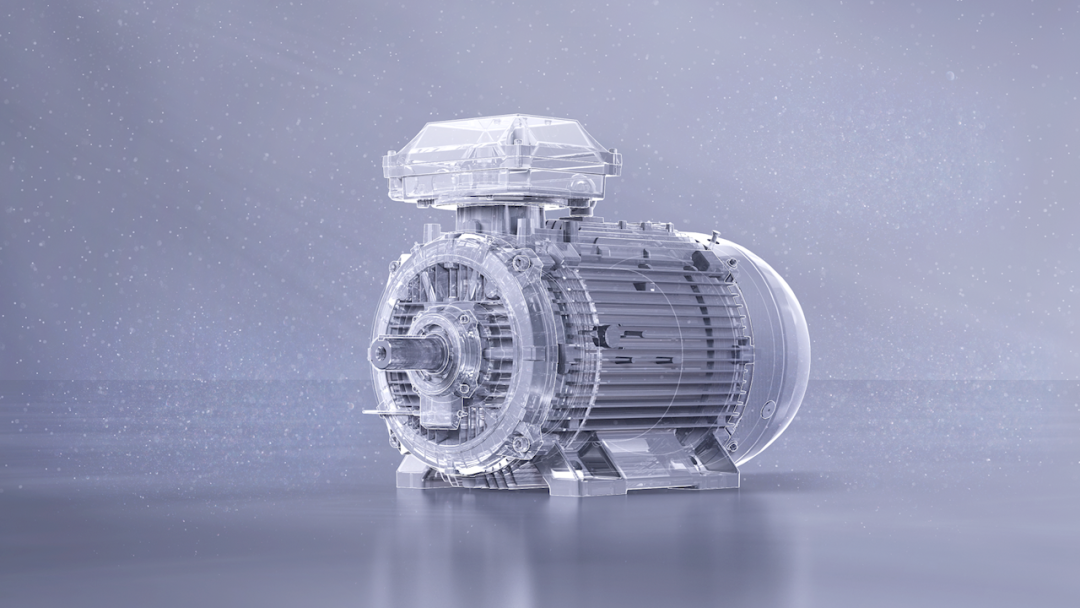

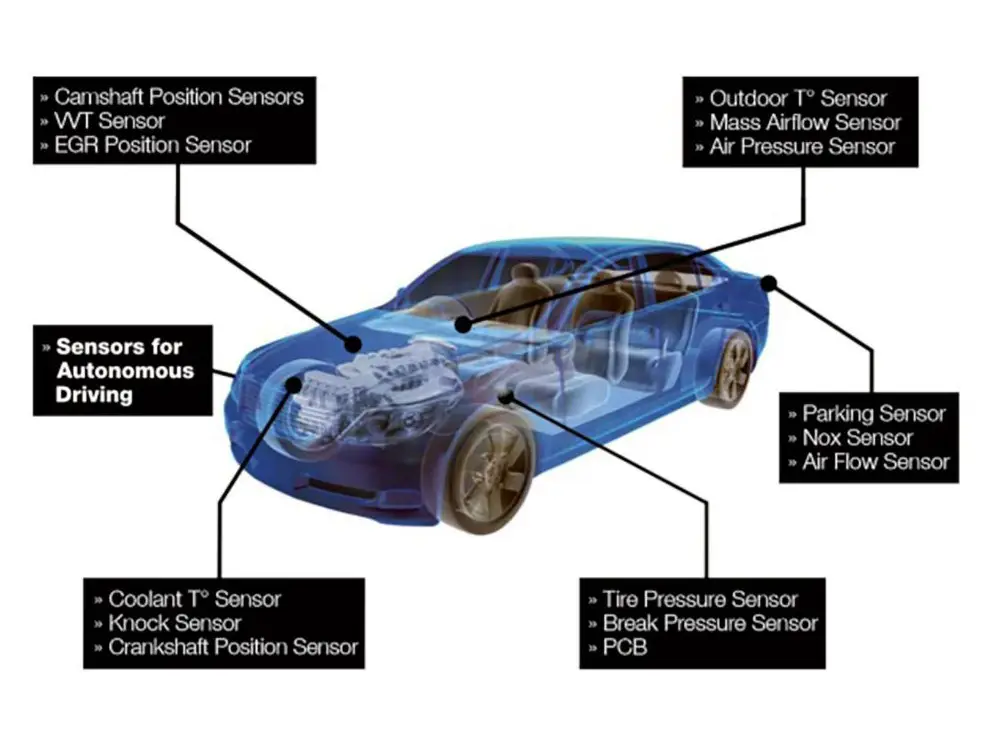

Since electric vehicles (EVs) have established a strong presence in the automotive market, manufacturers have been driving advancements in higher-power drivetrains, larger battery capacities, and faster charging speeds. To meet customer demands and extend driving ranges, EV manufacturers continue to increase battery energy capacity. However, larger batteries come with longer charging times. As the era of internal combustion engines as the primary power source for vehicles wanes, electric motors have emerged as the favored alternative. Original equipment manufacturers (OEMs) in the automotive industry are looking to the semiconductor sector for the electronic innovations necessary to achieve this electrified future. While many are excited by the gadgets and features inside vehicles, driving range and charging capabilities remain key concerns.

Understanding the Role of EV Charger Converters

The rapid development of the EV market has brought significant advancements, but the charging speed of vehicle batteries and the time required remain major hurdles. Improving battery charging speed and efficiency is a key factor in determining whether EVs can fully replace combustion vehicles.

How EV Charger Converters Optimize Charging Speed: Enabling High-Speed Charging

Wide-bandgap (WBG) technologies, such as silicon carbide (SiC), have greatly benefited automotive power conversion. Compared to traditional power devices like IGBTs, WBG technologies provide significant advantages. Passive component manufacturers have also been innovating. New inductor designs ensure that WBG technologies can support faster switching topologies, enabling greater range and faster, more reliable charging.

With EV revenue projected to exceed $620 billion by 2024 and grow at an annual rate of 10%, the demand for advanced SiC MOSFETs and improved passive components is clear. Engineers are increasingly focused on evaluating these technologies to improve charging performance and range.

Managing Power Conversion Efficiency

Power efficiency is critical to minimizing heat loss, saving energy, and meeting design weight and space constraints. Electric vehicles are increasingly seen as potential sources for balancing grid disturbances (vehicle-to-grid, V2G) or providing emergency power for homes (vehicle-to-home, V2H). This necessitates bidirectional charging topologies, leading to innovations like totem-pole PFC, dual active bridge (DAB), and LLC DC/DC converters.

SiC-based power converters, known for their high efficiency and power density, are becoming increasingly popular in power electronics. SiC devices are rapidly adopted in energy infrastructure, including solar, UPS systems, storage, and EV charging systems, for their ability to enhance efficiency and power density—key considerations for addressing environmental and energy costs.

Adaptive Charging Technologies and Smart Charging System Integration

Principles of Smart Charging Systems

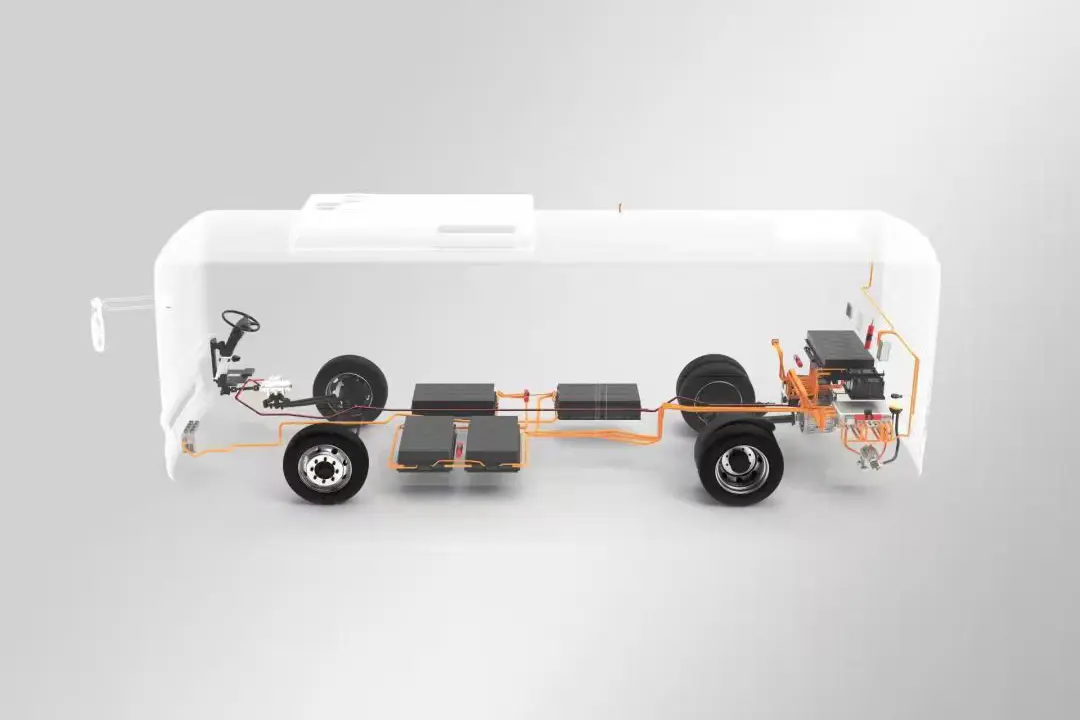

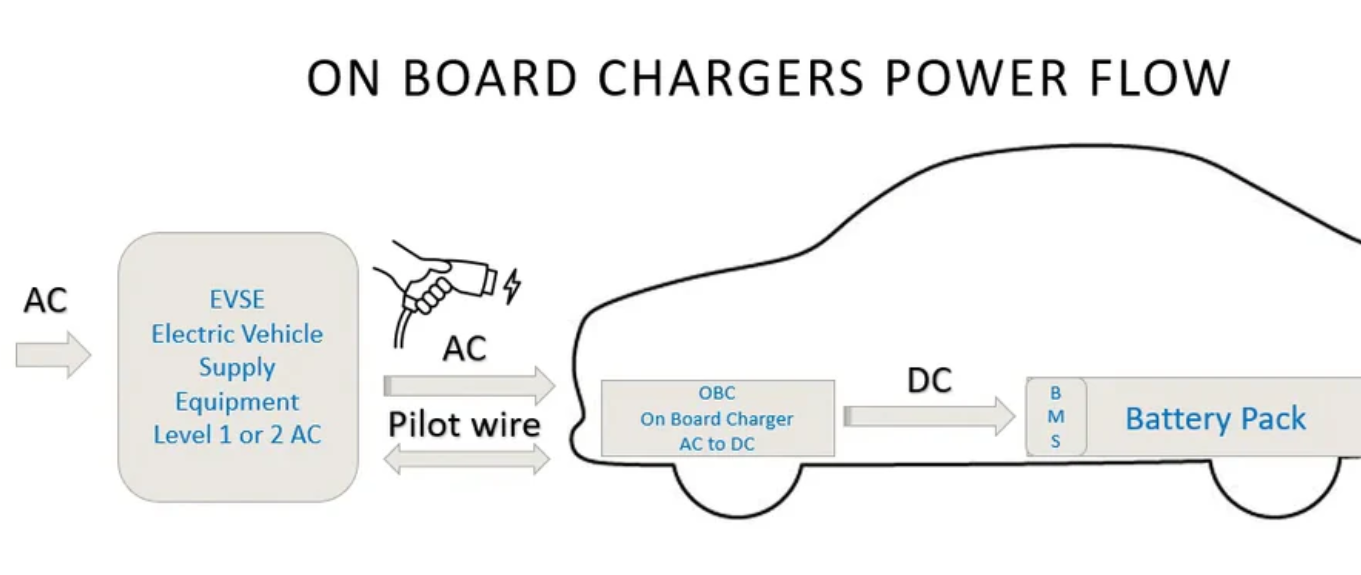

Smart charging systems are integral to EVs, managing high-voltage and low-voltage networks and their communication. Here’s how they work:

-

High-Voltage Network:

- Fast charging systems convert AC from charging stations into high-voltage DC power for direct battery charging, often at power levels reaching hundreds of kilowatts.

- Slow charging systems use onboard chargers (OBCs) to convert external AC power into DC for charging, suitable for home or workplace environments.

-

Low-Voltage Network:

- DC/DC converters step down high-voltage battery power to 12V or 24V for auxiliary systems.

- Battery Management Systems (BMS) monitor and control battery states to ensure safe charging and communicate with OBCs and DC/DC converters via CAN signals.

-

Charging Process:

- Upon connecting the charging plug, the OBC verifies the connection and sends a charging request to the BMS.

- The BMS assesses the battery status and responds, executing high-voltage power-up or power-down steps.

- Charging involves coordinated steps including AC power supply, system wake-up, charging demand detection, charging commands, and stopping.

Through these processes, smart charging systems ensure safe and efficient charging while meeting various environmental and operational requirements.

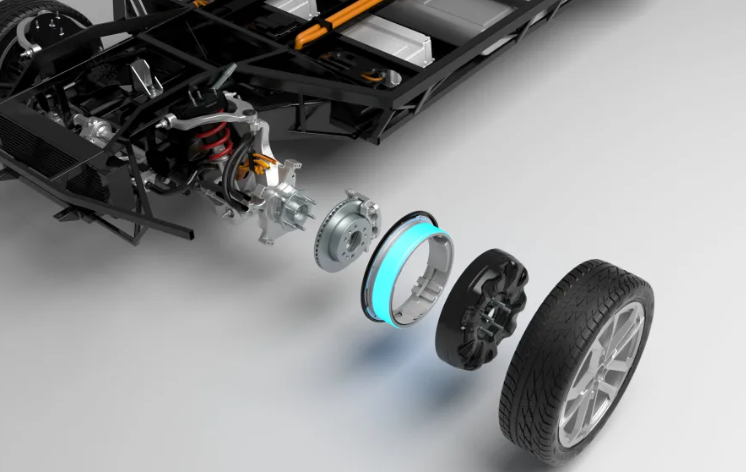

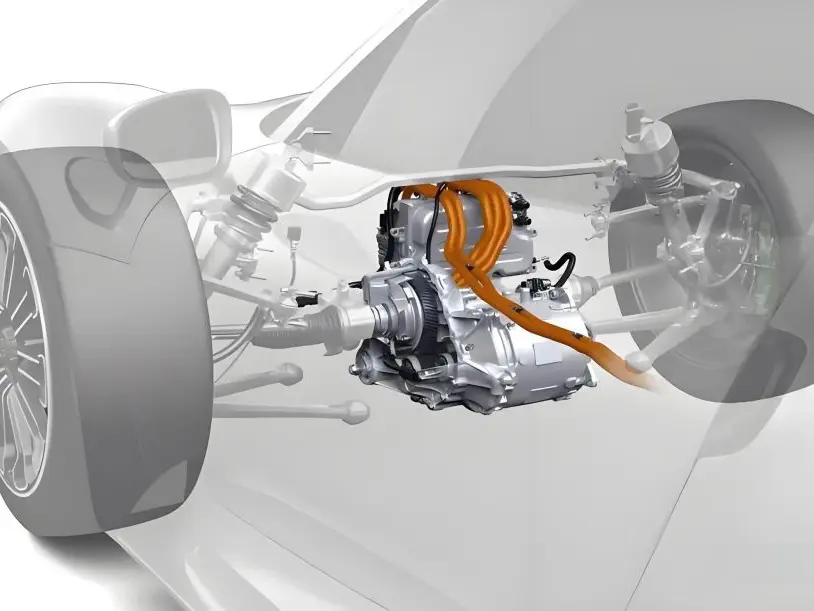

An integrated onboard charging system has garnered sustained attention from academia and industry. Its general structure, as illustrated below, features several distinct principles and advantages:

-

General Principle:

When parked, the electric motor drive system in an electric vehicle is reconfigured into a charger, allowing grid power to charge the battery. This enables time-sharing reuse of the drive motor and power components, requiring minimal or no additional power components. This approach offers significant advantages in terms of cost, weight, and volume. -

Reconfiguration Features:

- The motor windings generally function as the grid-side inductance.

- The drive inverter is typically reconfigured as a fully controlled rectifier or DC converter to complete the energy conversion and charge the vehicle's power battery.

-

High-Power Fast Charging Potential:

Generally, the power level of an electric vehicle's drive system far exceeds that of its charging system. Theoretically, this allows integrated onboard chargers to achieve high-power, fast charging.

Given these advantages, the concept of integrated charging systems has been extensively researched since its inception in 1985. In recent years, with the rapid development of modern power electronics and motor drive control technologies, various integrated charging systems based on different motor types and topologies have emerged, each with unique characteristics and performance. Summarizing and analyzing these topologies and control methods is essential for guiding future research.

On the other hand, the electric vehicle industry has higher demands for motor speed regulation and fault tolerance. Hybrid excitation motors, which inherit the high efficiency and power density of traditional permanent magnet motors while offering direct magnetic field regulation like electrically excited motors, are gaining increasing attention in electric vehicles. Their unique structure and electromagnetic characteristics provide significant advantages for integrated charging systems, offering new technological solutions for their development.

Benefits of Optimized EV Charger Converters

Charging convenience remains a critical challenge. While drivers can charge their EVs overnight at home or during the day at workplaces, these methods provide varying power levels. Enhanced Onboard Charger (OBC) capacities address lengthy charging times but add complexity and design challenges. The shift from 400V to 800V battery systems is improving both charging speed and power output efficiency while reducing charging currents, thereby shortening overall charging times.

Key factors like voltage and switching frequency influence OBC design. By increasing these parameters, OBC capacity can improve significantly. SiC-based 1200V devices are now favored for their higher blocking voltage capabilities, meeting the demands of next-generation EV platforms.

Key Features of Advanced EV Charger Converters

1. High Voltage Step-Down Conversion Ratio

Integrated DC-DC converters can extract power from high-voltage batteries and deliver it to low-voltage devices like 12V batteries.

2. Elimination of Circulating Current

New converter designs include special absorption circuits to eliminate circulating currents, boosting power conversion efficiency.

3. Low Output Current Ripple

By adopting forward converter modes, converters reduce output inductor current ripple, ensuring smoother power delivery.

4. Integrated OBC Functions

Advanced EV charger converters integrate OBC functions, enabling grid-to-vehicle (G2V) charging, vehicle-to-grid (V2G) discharging, and efficient power transfer between main and auxiliary batteries.

5. Design Considerations

· High step-down ratios ensure effective voltage conversion.

· Reduced output ripple ensures stable power for sensitive components.

These features provide high efficiency and reliability while enhancing overall system performance and usability.

Conclusion

Electrification and intelligent technology are driving the automotive industry forward. Advances in battery technology empower EV growth, while smart systems improve safety and efficiency. As EV market share continues to grow, these innovations will play a pivotal role in transforming the transportation landscape.