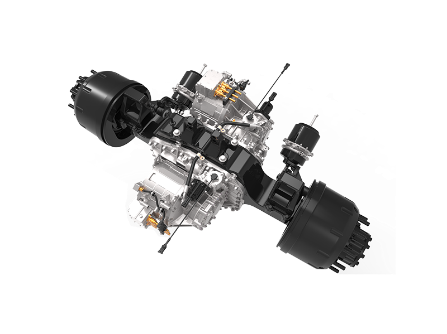

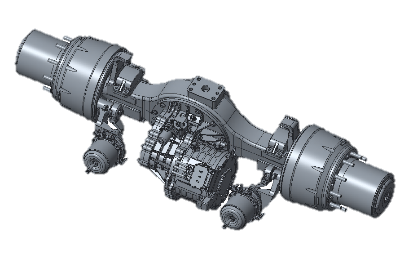

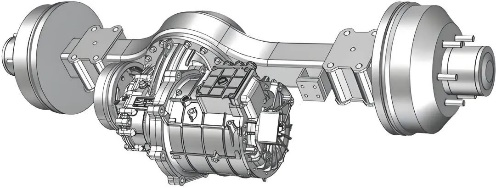

Pumbaa 130/286kW Integrated e-axle for electric sanitation trucks/heavy-duty trucks/tractor

Pumbaa PMEA45000Z Integrated e-axle Specification

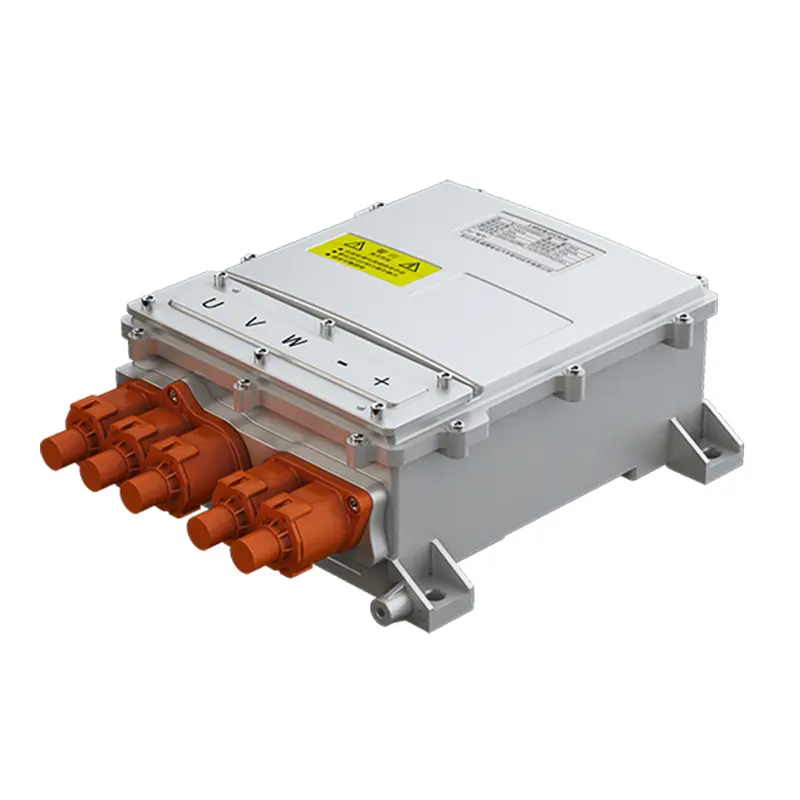

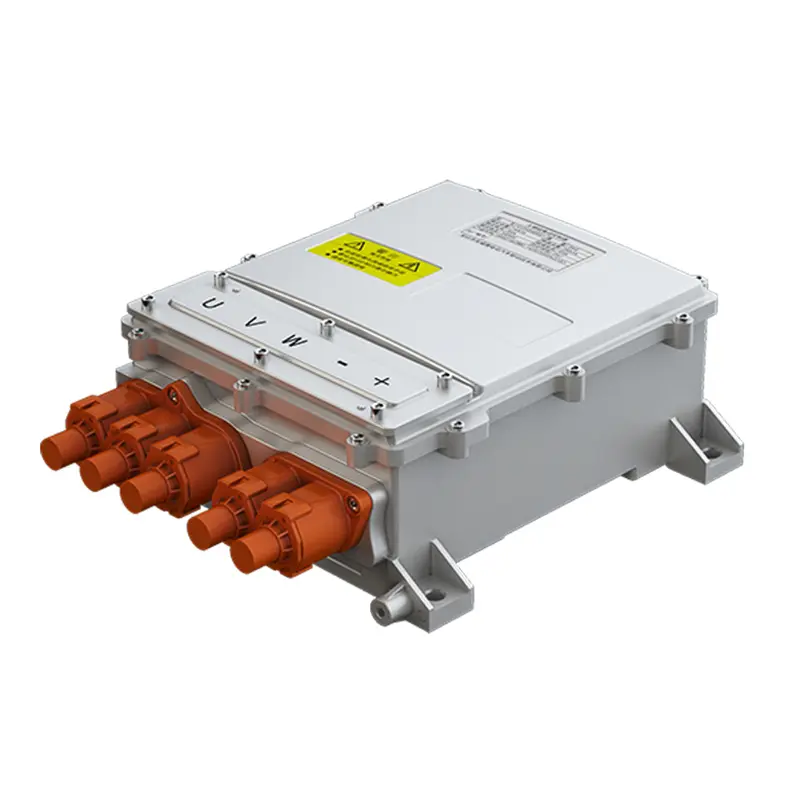

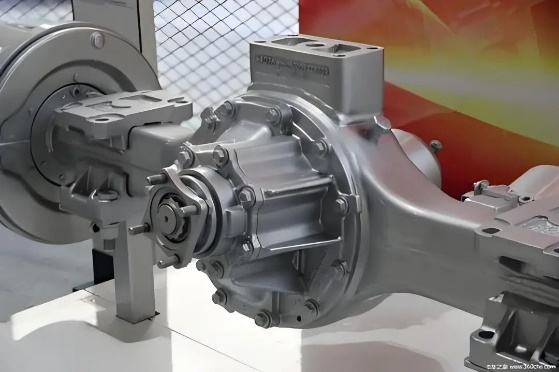

AMT/Basic drive structure: dual-motor drive + 2-speed AMT

|

Drive motors |

Rated/peak power |

72/160kW |

|

(Dual-drive motor) |

Nominal/peak torque |

156/380Nm |

|

|

Maximum speed |

10000rpm |

|

Gearbox |

Gearbox ratio |

70.44~8.25 |

|

Gear shift form |

AMT |

|

|

Assembly |

Rated axle load |

13000kg |

|

Output Power Rated/Peak |

130/286kW |

|

|

Wheel end output torque |

44570Nm |

|

|

Ground clearance of the bridge package |

≥300mm |

|

|

Total weight |

≤950kg |

|

|

Mounting interfaces |

Leaf spring mounting distance(mm) |

1020-1040可选 |

|

Rim mounting distance(mm) |

1836 |

|

|

Overall width(mm) |

2420 |

|

|

Brake specifications |

Drum pose/φ410×220 |

|

|

Air chamber size/connection size(mm) |

30/30 M16×1.5 |

|

|

Maximum braking torque(0.8MPa) |

2×18000Nm |

|

|

Wheel bolt specifications and distribution |

2-10×M22×1.5/Φ335 |

|

|

Locate the stop(mm) |

Φ280.8 |

description2

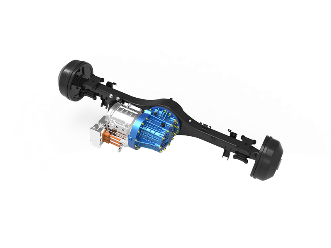

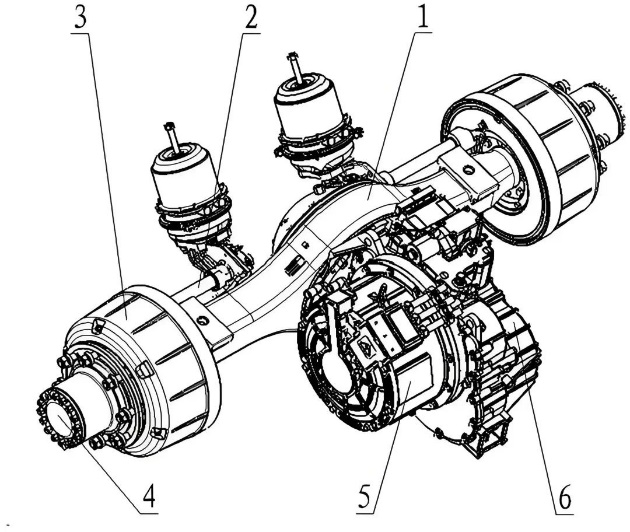

PMEA45000Z Integrated e-axle Application

Pumbaa PMEA45000Z Integrated e-axle is designed for use in 18T sanitation truck.

Our electric axle for trucks incorporates cutting-edge motor and transmission technology, delivering a seamless driving experience with high-speed operation and intelligent thermal management. Whether for urban logistics or long-haul transportation, the truck e-axle ensures superior efficiency and sustainability.

.png)

PMEA45000Z Integrated e-axle Application

Pumbaa PMEA45000Z Integrated e-axle is designed for use in 18T loading truck. Our PMEA45000Z Integrated E-Axle is designed for next-generation electric trucks, providing high efficiency, superior power, and unmatched durability. With an optimized electric axle system, your fleet benefits from enhanced performance, reduced energy consumption, and lower operational costs.

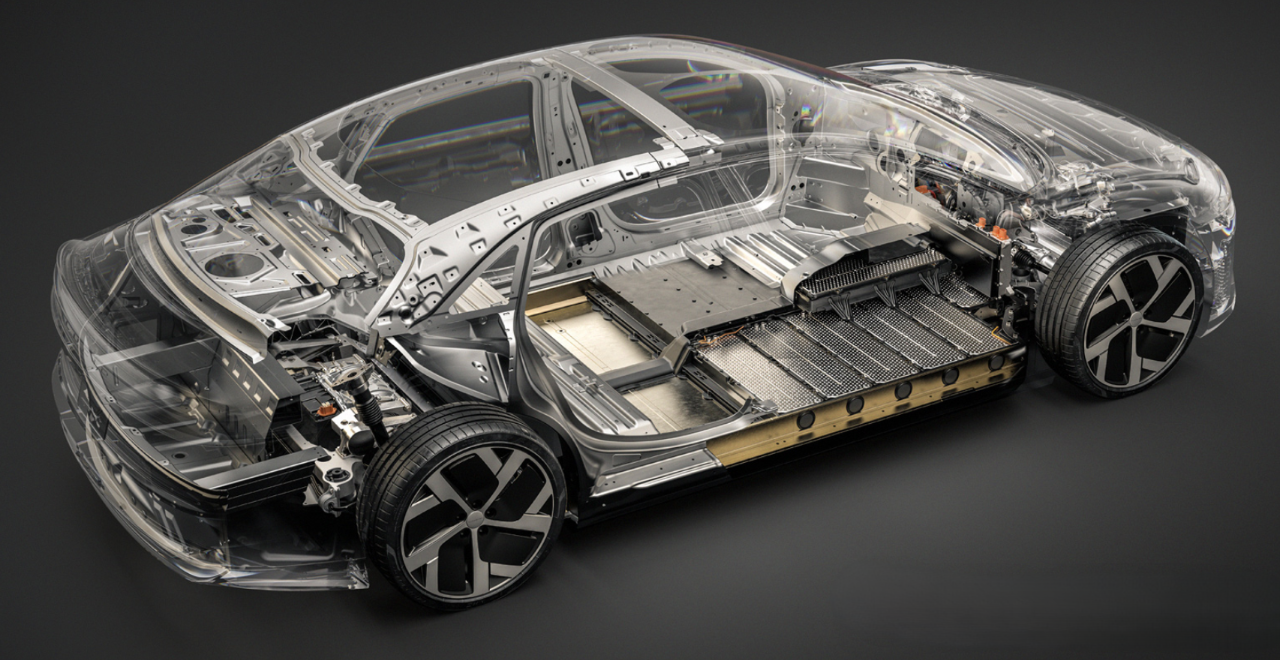

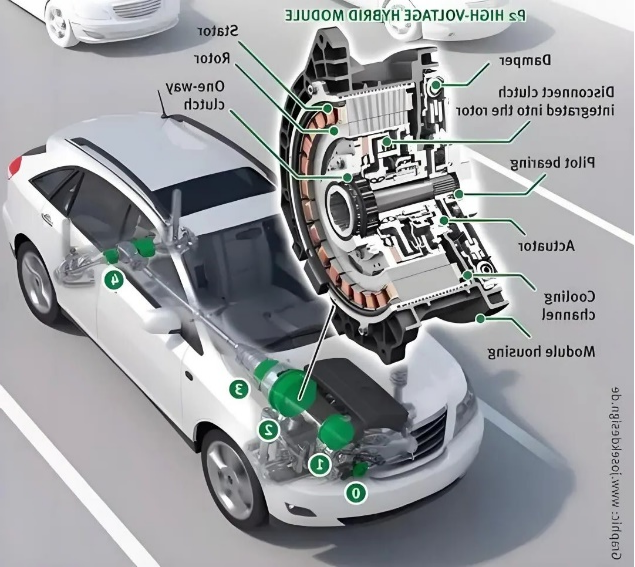

The composition and development trend of electric axles

The electric drive axle is a mechatronics drive system designed for electric vehicles, which has the advantages of high degree of integration, small size and low energy consumption. As the core component of electric vehicles, its performance directly affects the power and economy of electric vehicles. The electric drive axle is derived from the traditional axle and is the transmission system of the car, which plays the functions of bearing load, reducing the speed, increasing torque, ensuring the difference between the left and right wheels, and braking.

1.Overview:

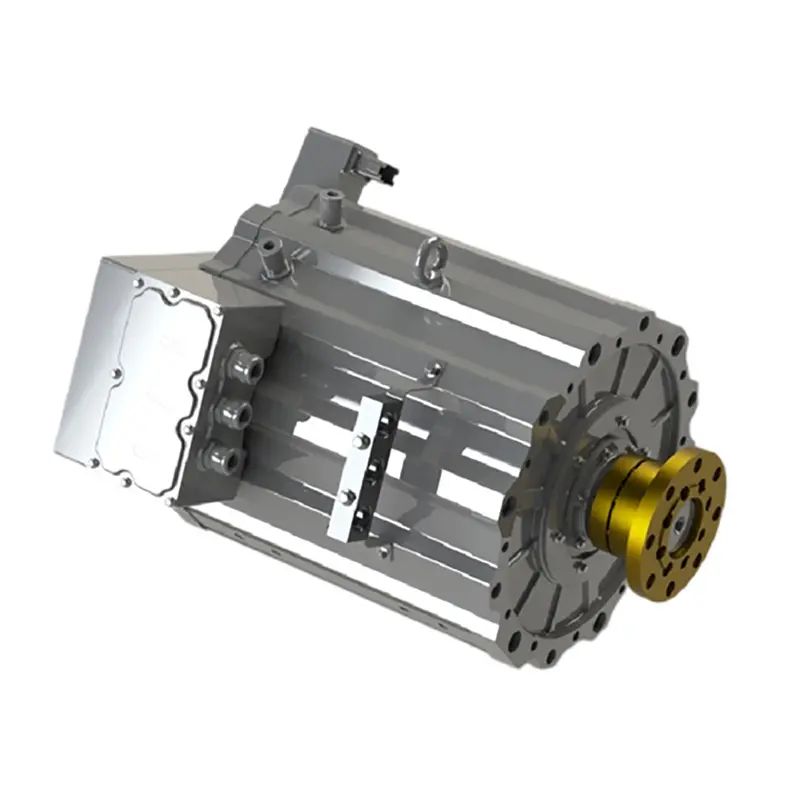

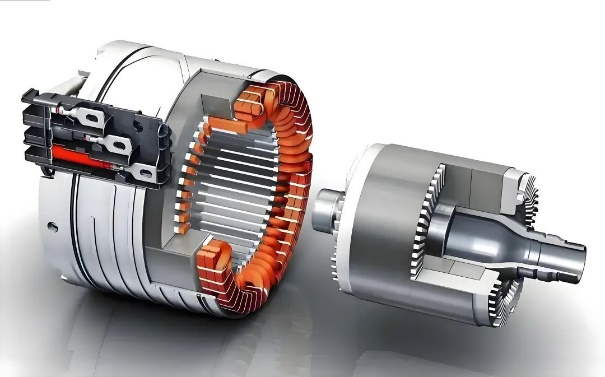

The electric drive axle is mainly composed of components such as electric motors, reducers, and differentials.

Among them, the electric motor is the core part, which is directly connected to the wheels, and converts electrical energy into mechanical energy through the principle of electromagnetic induction, driving the wheels to rotate.

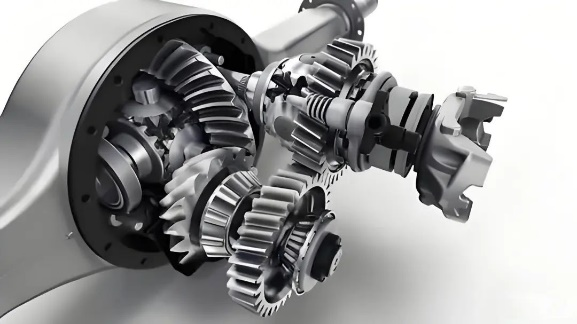

The reducer converts the high-speed rotation of the electric motor into low-speed rotation to ensure the stable driving of the vehicle.

The differential is used to adjust the speed of the left and right wheels to ensure the steering and driving stability of the vehicle.

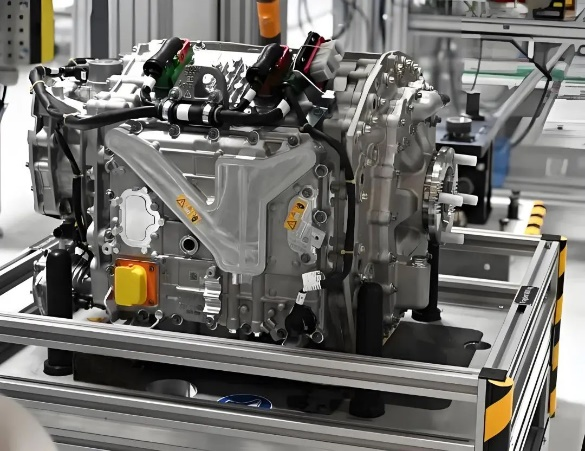

2.How an electric axle works

The electric axle drive wheel is a drive device consisting of a motor and a reducer, which converts electrical energy into power to push the tires. Here's how it works:

1. Motor: The core of the electric drive axle drive wheel is the motor, which is converted into power through electric energy. The output shaft of the motor is connected to the input shaft of the reducer, which transmits the driving force to the reducer.

2. Reducer: The function of the reducer is to convert the high-speed and low-torque output by the motor into low-speed and high-torque, so that the electric axle transmission wheel can provide greater driving force to promote the vehicle.

3. Transmission wheel: The transmission wheel is the output of the transmission wheel of the electric drive axle, which transmits the power transmission to the wheel, so that the wheel can generate power and push the car forward.

3. Advantages of electric axles

(1) Easy operation: The electric drive axle does not need to shift gears, and the vehicle can be accelerated, decelerated and braked through electronic control.

(2) Low energy consumption: The electric drive axle drives the vehicle through electric energy, and the energy consumption is lower than that of the traditional internal combustion engine drive axle.

(3) Good shock absorption effect: The motor of the electric drive axle has a certain shock absorption effect, which can reduce the bumpiness of the vehicle when driving.

4. Disadvantages of electric axles

(1) High price: Under the same configuration, the price of electric drive axle is higher than that of traditional internal combustion engine drive axle.

(2) Short range: Due to the limitation of battery capacity, the range of the electric drive axle has certain limitations.

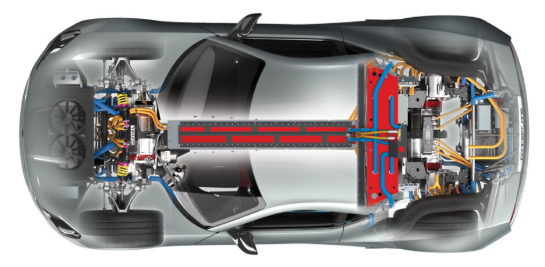

5. The development trend of electric axles

With the continuous progress of science and technology, electric drive technology has become an important part of modern industry and transportation. With the advantages of high efficiency, environmental protection and energy saving, it is gradually changing the traditional driving mode and becoming an important force to promote the sustainable development of society.

(1) Improvement of high-efficiency technology: With the continuous development of materials science, power electronics and control theory, electric drive technology will pay more attention to high-efficiency improvement.

(2) Application of lightweight materials: It is one of the important directions for the development of electric drive technology. By using lightweight, high-strength materials, such as carbon fiber, aluminum alloy, etc., the mass of the electric drive system can be effectively reduced, and its power density can be improved, thereby enhancing the vehicle's dynamic performance and range.

(3) Intelligent control system: With the rapid development of artificial intelligence and big data technology, the level of systematic control of electric drive will be significantly improved. The intelligent control system can realize real-time monitoring and predictive maintenance of the electric drive system, improve the operation efficiency and reliability of the system, and reduce maintenance costs

(4) Green drive: As a clean and green energy conversion method, electric drive technology will receive more and more attention.

(5) Integration and modularization: In order to improve the reliability and maintenance of the electric drive system, the future electric drive technology will tend to be integrated and modularized to improve the reliability and maintenance of the system.

(6) Cost reduction and optimization: With the large-scale application of electric drive technology and the reduction of production costs, the cost of electric drive system will gradually approach or even lower than that of traditional drive methods. This will further promote the wide application of electric drive technology in various fields and promote the sustainable development of society.

(7) Reliability enhancement: Reliability is one of the key factors for the continuous development of electric drive technology. It can significantly enhance the reliability of the electric drive system and provide a strong guarantee for its application in more fields.

(8) With the continuous maturity and cost reduction of electric drive technology, its application field will be further expanded. In addition to traditional automobiles, electric vehicles and other fields, electric drive technology is also likely to be widely used in aerospace, shipbuilding, industrial machinery and other fields, providing a strong impetus for the innovation and development of various industries.

Conclusion

In short, electric drive technology is in a stage of rapid development, and its advantages of high efficiency, environmental protection and energy saving will make it play a more important role in the future society. With the continuous progress of technology and the continuous expansion of application fields, electric drive technology will make an important contribution to the sustainable development of society.

Leave Your Message

Blog

China’s getting a big electric car battery swapping boost in 2025. Would that work across the globe?

Pumbaa's Superior Electric Motor Service: Leading sales center for electric motors

EVs Could Last Much Longer Than You Think