PUMBAA Electric Vehicle Motor Controller Unit (MCU) PMC32A

Technical features of the Electric Commercial Vehicle Motor Controller Unit (MCU)

Motor speed controller is the control unit that controls the motor to drive the whole vehicle, and belongs to the core components of electric vehicles. Motor speed controller has CAN communication function, over-current protection, overload protection, under-voltage protection, over-voltage protection, phase loss protection, energy feedback, power limit, high voltage interlock, fault reporting and other functions. The motor controller technology is relatively mature at present, it has the characteristics of high integration, high power density, long life, stable output, etc.

description2

Components of the Electric Commercial Vehicle Motor Controller Unit (MCU)

The electric motor speed controller unit consists of an inverter and a controller. Among them, the inverter receives the DC power delivered by the battery and converts it into three-phase AC power to power the car motor. Next, the electric motor speed controller unit receives signals such as motor speed and feeds them back to the instrument. When braking or acceleration occurs, the frequency of the electric motor spped controller unit increases or decreases, thus achieving acceleration or deceleration.

description2

Specification of the Electric Commercial Vehicle Motor Speed Controller Unit (MCU)

|

Model |

Cooling Method |

Overall Dimensions |

Voltage Range |

Rated Current |

Peak Current |

Protection Grade |

Weight |

Applications |

|

PMC32A |

Water cooling |

505*449*143 |

450-750 |

360 |

720 |

IP67 |

25 |

Bus, heavy truck, Mining trucks |

description2

Application of motor speed controller

Coach

Heavy truck

Heavy truck

Mining trucks

description2

Electric vehicle Motor controller structure and working principle

Motor Controller, as one of the core components of electric vehicle, is the decisive factor of vehicle power performance. It obtains the requirements of the whole vehicle from the whole vehicle controller, obtains the electric energy from the power battery pack, modulates by its own inverter, obtains the current and voltage needed to control the motor, and provides it to the motor, make the motor speed and torque to meet the requirements of the vehicle.

The Motor controller is a central nervous system that connects the motor and the battery to adjust the vehicle's various performance. The intelligent electronic control can not only ensure the basic safety and accurate control of the vehicle, also can let the battery and the motor play the sufficient strength.

Composition

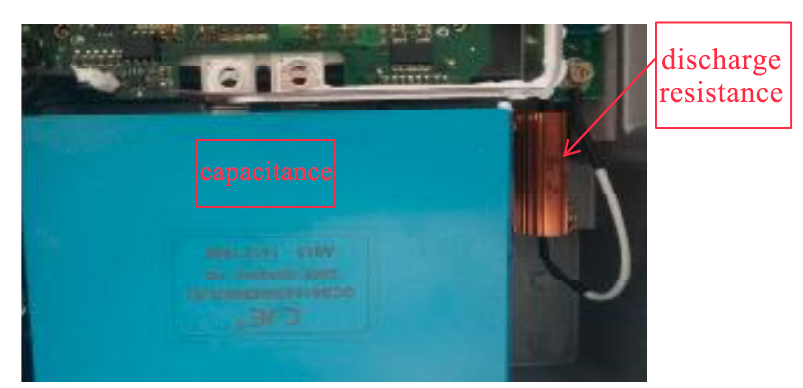

The Motor controller is divided into two parts: low-voltage and high-voltage. The low-voltage part includes input-output interface circuit, Control Motherboard, arithmetic unit, memory, sensor, etc. The high voltage part includes IGBT module, drive motherboard, Super Capacitor, discharge resistance, DC high voltage connector, UVW connector and so on.

The Motor controller housing is provided with a water channel inside the housing and an inlet and outlet pipe joint outside the housing. The outlet pipe under the radiator is connected to the pump, which sends coolant to the Motor controller to cool IGBT components, which then flow into the motor and back to the return pipe above the radiator.

Second, the role of the components

(1) Input/output interface circuit, responsible for external input signal and control motherboard conversion connection, responsible for control motherboard output signal and external conversion connection.

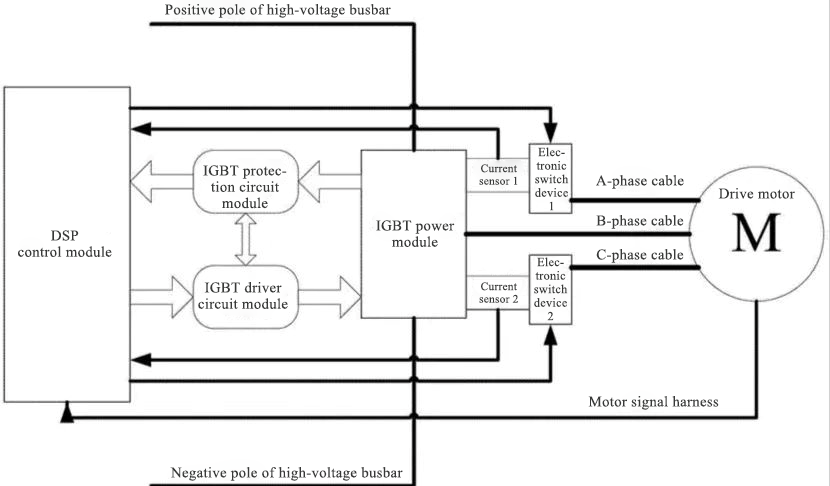

(2) Control motherboard, communicate with VCU, supply power to the sensor, analyze the signal, control IGBT, monitor the current of high voltage DC bus, monitor the temperature of IGBT module, monitor the connection of high voltage plug.

(3) Drive the motherboard, accept the control motherboard instruction, control each IGBT open or open.

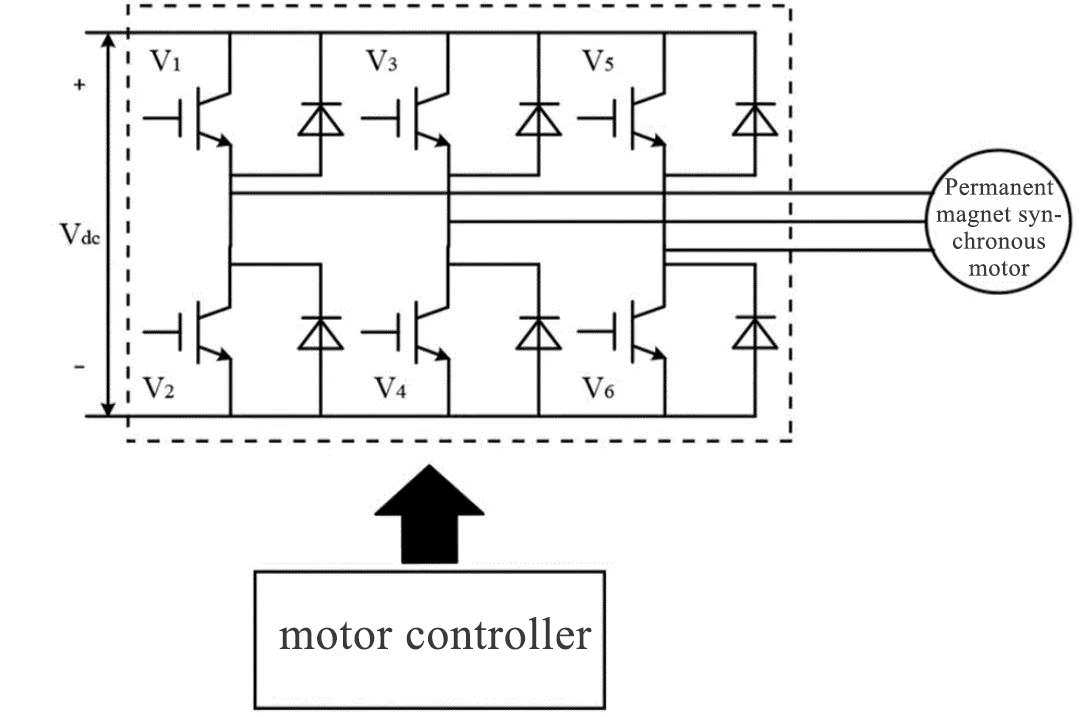

(4) IGBT (insulated-gate bipolar transistor) , which converts DC to three-phase electric power and converts frequency to control motor speed and rotation direction, recovers energy when the vehicle decelerates, and converts three-phase electric power to high voltage DC, charge the power battery.

(5) Ultracapacitor, ultracapacitor and high-voltage DC bus parallel connection, the role is to start the motor to maintain voltage stability.

Three. Principle

The motor is driven by modulating the output sine wave through an inverter bridge, and the multi-in-one controller includes a distribution circuit. Provide power distribution for each part of the integrated controller, such as TM (power transformer) contactor, fuses, electric air conditioning circuit power supply, electric defrosting circuit power supply, etc.

IGBT drive circuit: Receive Control Signal, Drive IGBT and feedback status, provide voltage isolation and protection.

Auxiliary power supply: Supply Power for control circuit, supply isolated power for drive circuit.

DSP circuit: receive vehicle control instructions, and provide feedback information, detection motor system sensor information, motor control signal transmission according to the instructions.

Structure and cooling system: provide cooling for Motor controller, controller installation support, controller safety protection.

Four. Function

(1). control the positive and negative rotation of the motor, the positive rotation of the motor vehicle forward, reverse the motor reverse vehicle.

(2). speed control, according to the driver's instructions to perform acceleration, uniform speed, deceleration, etc.

(3). control crawling, put D or R gear, lift the brake pedal, do not step on the accelerator pedal, the vehicle slowly.

(4). energy recovery, also known as kinetic energy feedback, when the motor into a generator.

(5). communication function, communicate with other control unit and gateway through CAN bus.

(6). fault diagnosis, store fault code when self-diagnosis abnormal, and send it to VCU at the same time.

(7). protective function to protect Motor controller, drive motors and power batteries from exceeding the operating temperature limit.

(8). driving protection, it can increase anti-shake function according to the customer's demand in the course of driving to ensure the driving comfort.

description2