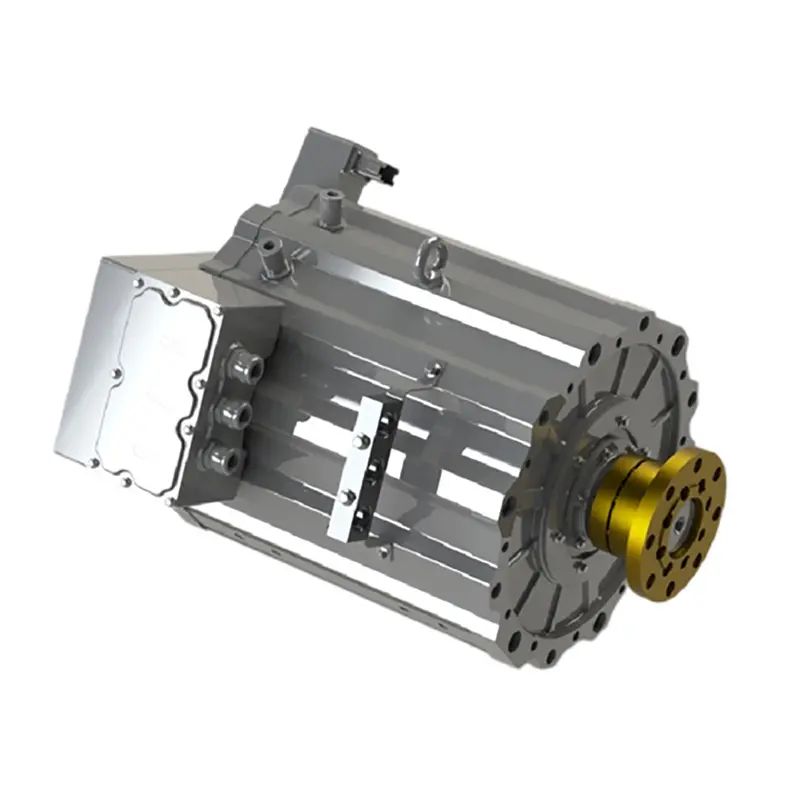

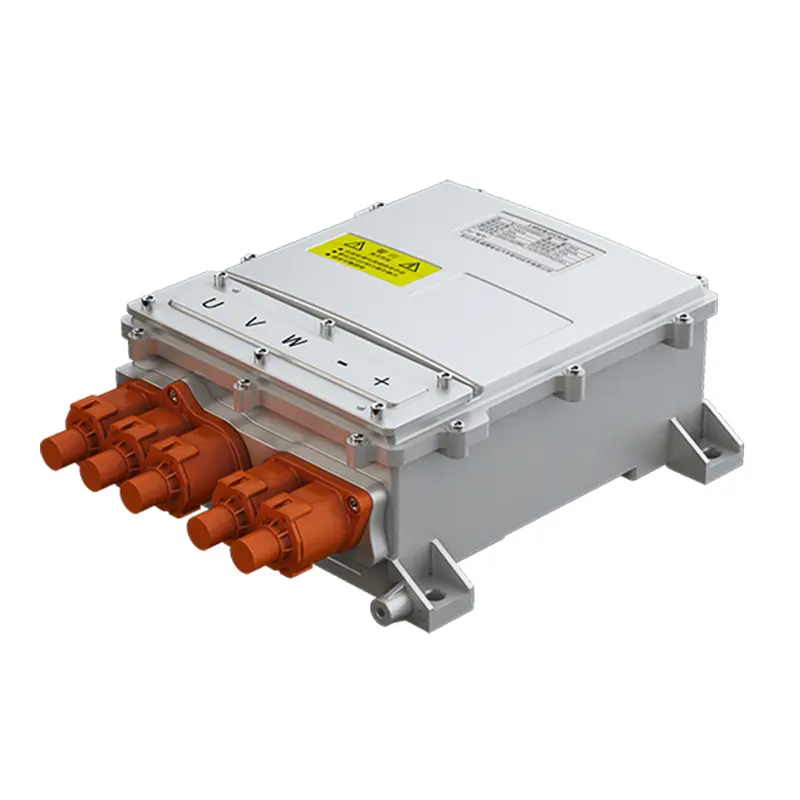

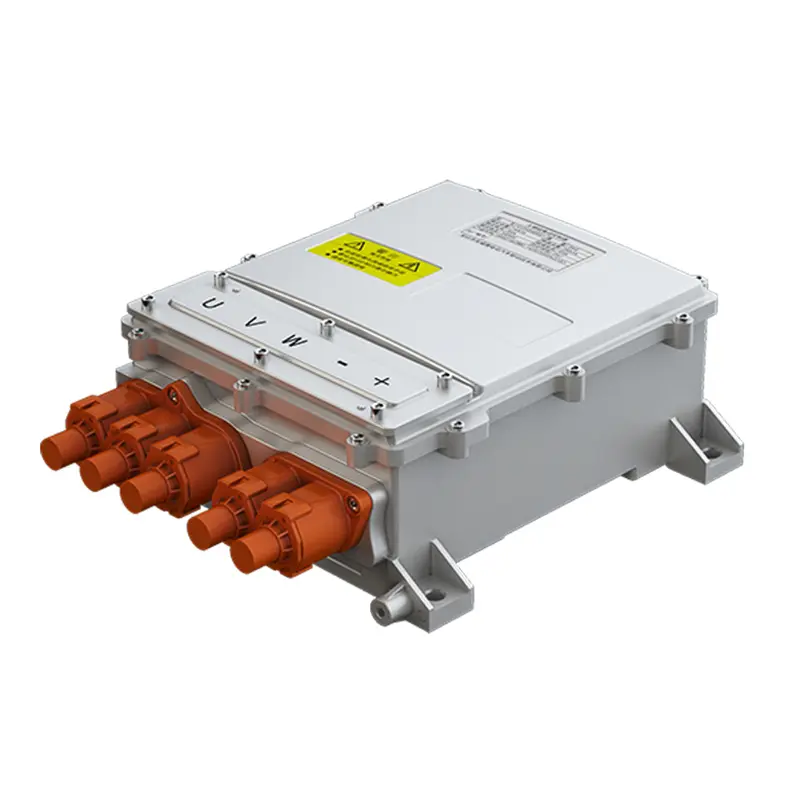

PUMBAA Electric Vehicle Drive Controller Unit PEVC007 (Applies to all models)

Benefits of the Electric Vehicle Drive Controller Unit

● Proven platform control algorithms available

● Hardware based on cost-effective, high-volume platform

● All necessary communication standards can be achieved

● Basic software according to AUTOSAR standard

● Integration platform for powertrain

● Charge communication, thermal management and battery management can be optionally integrated

● Advanced cyber security concepts

● Broad system know-how of vehicle E/E architecture with worldwide local support

● Perfect system architecture design and first-class energy management algorithm and control strategy

● Complete UDS fault diagnosis, including all components of the electrical drive subsystem fault diagnosis strategy

● Through EMC and other reliability tests, to meet the requirements of production-grade products

Our vehicle controller, electric vehicle control unit, and vehicle control unit in EV are designed to optimize performance and reliability for electric vehicles. These cutting-edge solutions provide precise control, seamless system integration, and enhanced energy efficiency. Perfectly suited for modern EV architectures, they ensure smooth operation, advanced diagnostics, and robust durability, making them ideal for both personal and commercial applications. Choose our products to power your EV with innovation and reliability.

description2

Product characteristics of the Electric Vehicle Drive Controller Unit PEVC007:(Applies to all models

|

Functional description |

Specifications |

||

|

VCU |

Input |

Low voltage |

DC 9-32V |

|

Can Channel |

3 channels, 2 isolated, 1 non-isolated |

||

|

Sensor Power |

6 channels 5V DC |

||

|

Analog input |

8-way voltage 0-5V, Resolution 10 bits |

||

|

Digital quantity input-low side |

9-way 0-2.1 V available |

||

|

Digital quantity input-high side |

Route 96-32v is available |

||

|

Duty cycle input |

4-way, amplitude 5-30V, duty cycle 0-100% |

||

|

Output |

Digital quantity output-high side |

8-way 8-32V effective |

|

|

Digital quantity output-low side 1 |

8 Road 0-2.84 V 500mA |

||

|

Digital quantity output-low side 1 |

8 Road 0-2.84 V 1a |

||

|

Duty cycle output |

4-way, amplitude 8-32V, duty cycle 0-100% |

||

|

System |

Operating temperature |

-40~80℃ |

|

|

Cooling mode |

Water cooling |

||

|

Size |

207L*135W*42H |

||

|

Weight |

About 0.5 kg |

||

|

Protection level |

IP67 |

||

description2

Pumbaa’s Electric Vehicle Drive Controller Unit(VCU)

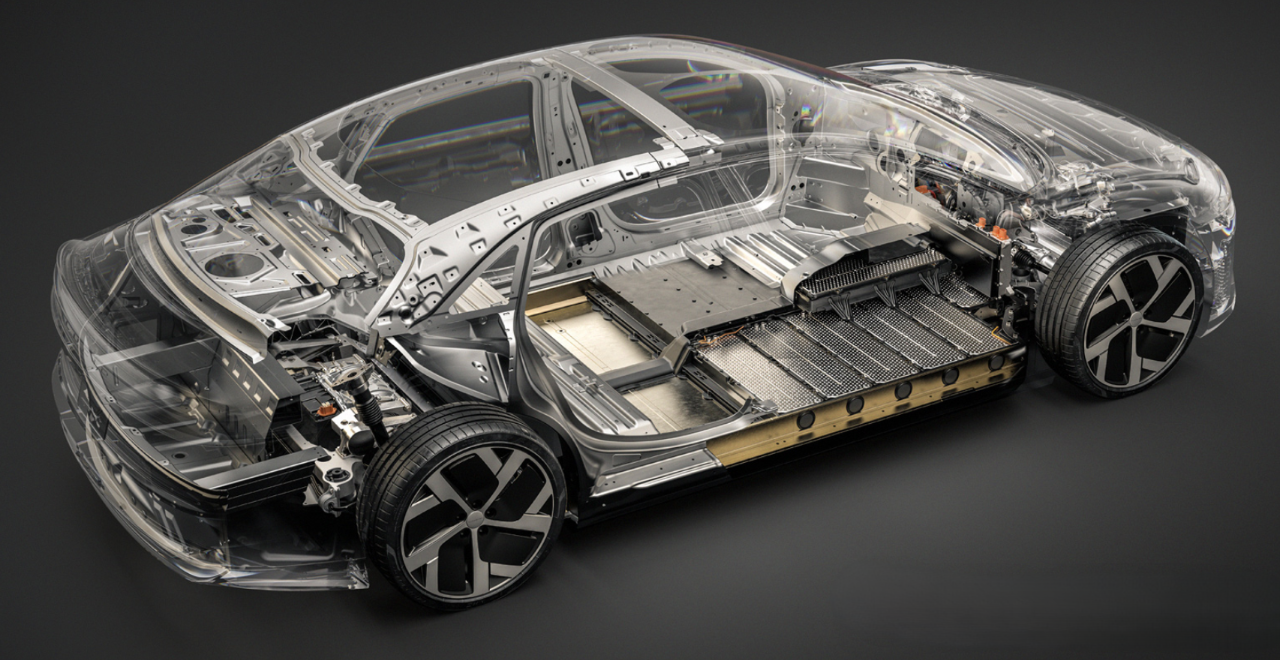

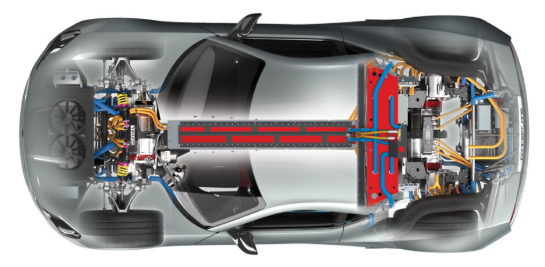

Powertrain diversification is on the rise. While there used to be little else than diesel and gasoline engines in the past, now powertrain solutions include all degrees of electrification. The centralized Powertrain Controller is the solution for the fact that functions and software are getting more complex and that interconnected functions require lots of processing power.

Versatile

Can handle the growing variant diversity and complexity in vehicles

Powerful

Makes processing power available with high-performance microcontrollers

Powerful in diverse applications

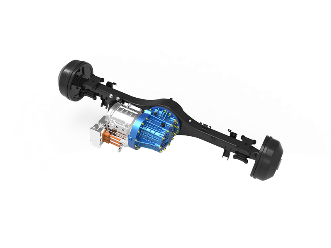

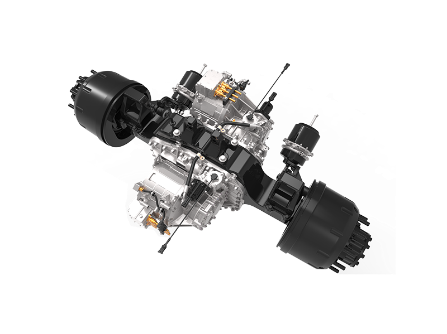

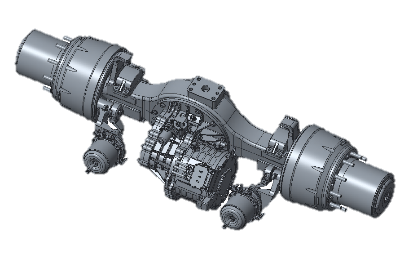

As a powertrain domain controller, the vehicle control unit can provide torque coordination, operation and gearshift strategies, high-voltage and 48V coordination, charging control, on board diagnosis, monitoring, thermal management, charge communication and much more for electrified and connected powertrains.

The vehicle control unit can be used in electrified passenger cars, trucks and Off-Highway vehicles but also in combustion engines applications.

The vehicle control unit also ensures fail-operational function for highly automated driving solutions.

Simple integration of new functions

The vehicle control unit coordinates the components in the powertrain or even assumes some of their functions. This includes control of the inverter and battery management system as well as transmission and engine control. Battery charging control (communication with the charging station via a standardized interface) can be integrated in the vehicle control unit as well.

In addition, the introduction of a new level of abstraction in the E/E architecture makes variant handling of changing powertrain components much easier and saves resources in the subsidiary component-related control units. Due to its modular and configurable hardware and software, the vehicle control unit can be flexibly designed to meet future requirements.

The vehicle control unit standard is available in two standard versions – vehicle control unit standard mid and vehicle control unit standard max – and is scalable to fit customer demands. It uses resource-optimized classic micro-controller technology based on the latest engine management generation.

description2

What’s Electric Vehicle Controller Unit(VCU)

Vehicle Controller VCU is the core control component of vehicle. With energy management, torque coordination and distribution, Motor Battery Coordination Management, safety monitoring, UDS fault diagnosis, braking energy recovery and other functions. The function and performance of VCU determines the driving, power, safety and economy of the whole vehicle.

The vehicle controller functions somewhat like the engine control unit of a fuel-powered vehicle. It is the “Brain” of the new energy vehicle control system, by collecting the signals of the power on the vehicle, the acceleration pedal, the brake pedal, the shift signal, the motor module, the controller, the actuator, the sensor and so on, based on the driving state of the vehicle and the intention of the driver, a comprehensive analysis is made and the corresponding decision is made, then the control signal is output to each lower part controller to control the electric vehicle to enter different operating modes, and display the key information in the vehicle instrument and the big screen.

The function of VCU vehicle controller is to collect various signals. VCU (Vehicle control unit) , as the central control unit of new energy Vehicle, is the core of the whole control system. The VCU collects the status of the motor and the battery, the acceleration pedal signal, the brake pedal signal, the actuator and the sensor signal, and makes the corresponding judgment according to the driver's intention comprehensive analysis, monitor the actions of the lower level component controllers. It is responsible for the normal running of the vehicle, braking energy feedback, the whole vehicle drive system and Power Battery Energy Management, network management, fault diagnosis and treatment, vehicle status monitoring, etc. , so as to ensure the vehicle in a better power, high economy and reliability of the normal and stable working state. It can be said that the performance of the vehicle controller directly determines the performance of the new energy vehicle, played a mainstay role.

VCU control function introduction

1. According to the driver's requirements, vehicle status, and other working conditions, reasonable control of motor working state and power output, to meet the driving conditions. Including acceleration and deceleration, constant speed, braking and backward working conditions.

2. Brake energy feedback control judge brake mode, calculate brake torque distribution and recover part of energy according to brake pedal and acceleration pedal information, vehicle running information and power battery loading status information.

3. Vehicle energy optimization through the coordination of Electric Vehicle Motor Drive system, battery management system, transmission system and other vehicle energy-consuming components and the tube to change the light, to obtain the best energy utilization ratio, extended use.

description2

Blog

China’s getting a big electric car battery swapping boost in 2025. Would that work across the globe?

Pumbaa's Superior Electric Motor Service: Leading sales center for electric motors

EVs Could Last Much Longer Than You Think